Polyimide film, and method for production thereof

A technology of polyimide film and manufacturing method, applied in the direction of chemical instruments and methods, other household appliances, synthetic resin layered products, etc., capable of solving the problem of property degradation, operability degradation, foaming of polyimide film, etc. Problems, achieve fast film-making speed, reduce heat energy and heating time, and reduce the effect of tensile physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples.

[0098] The physical properties of the self-supporting film and the polyimide film were evaluated according to the following methods.

[0099] (1) Initial elastic modulus, breaking strength, and breaking elongation of self-supporting film and polyimide film

[0100] The film was punched into the shape of a dumbbell (dumb-bell) according to the IEC450 standard. As a test piece, TENSILON manufactured by ORIENTEC was used to measure the initial modulus of elasticity, breaking strength, elongation at break.

[0101] (2) Imidization rate of self-supporting film

[0102]Using the Magna550FT-IR manufactured by Nikolai (Nikore), the FT-IR spectrum of the self-supporting film and its fully matured film (polyimide film) was measured using Ge crystal (GE Crystal) and the ATR method at an incident angle of 45°. Use 1775cm -1 The peak h...

Embodiment 1~19

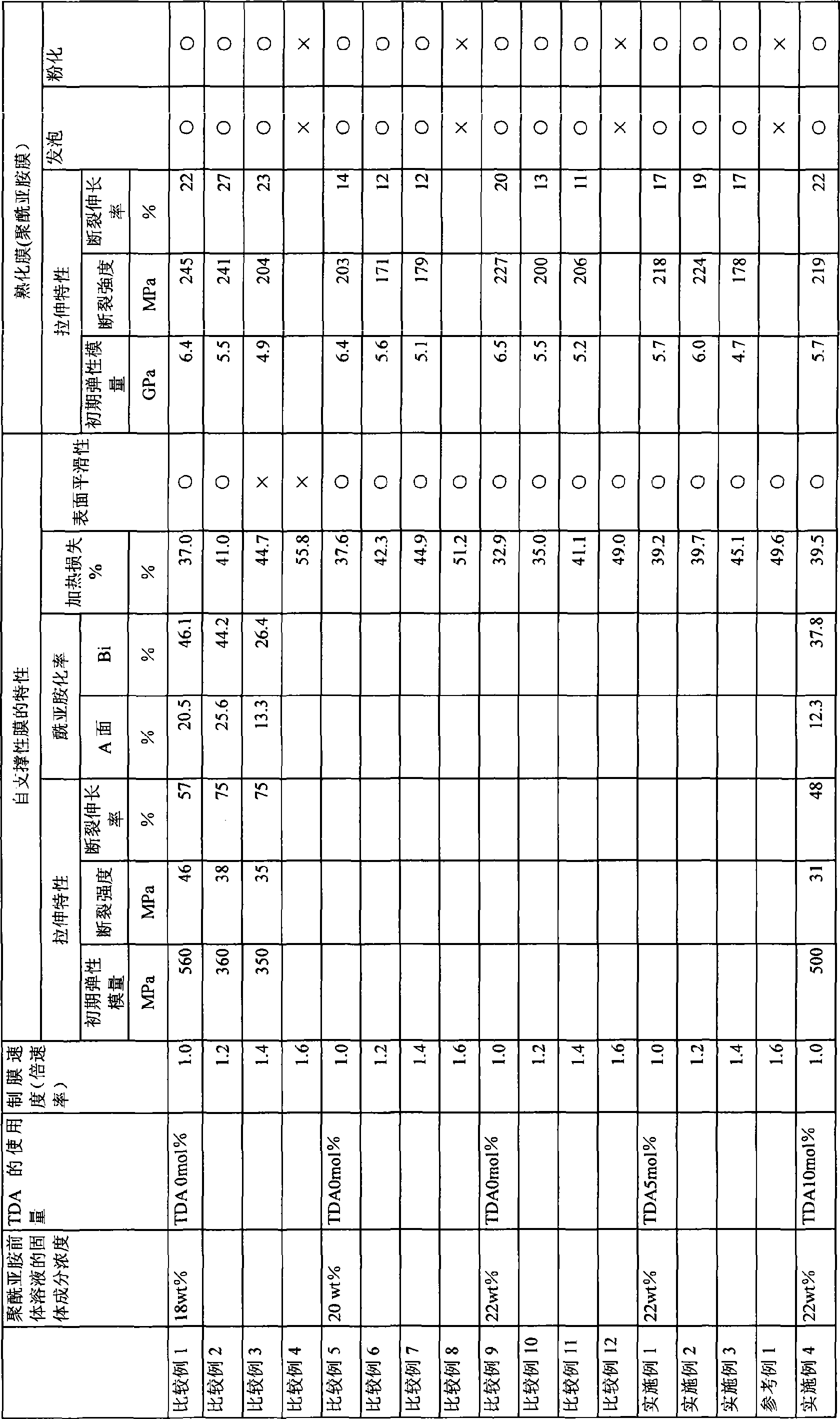

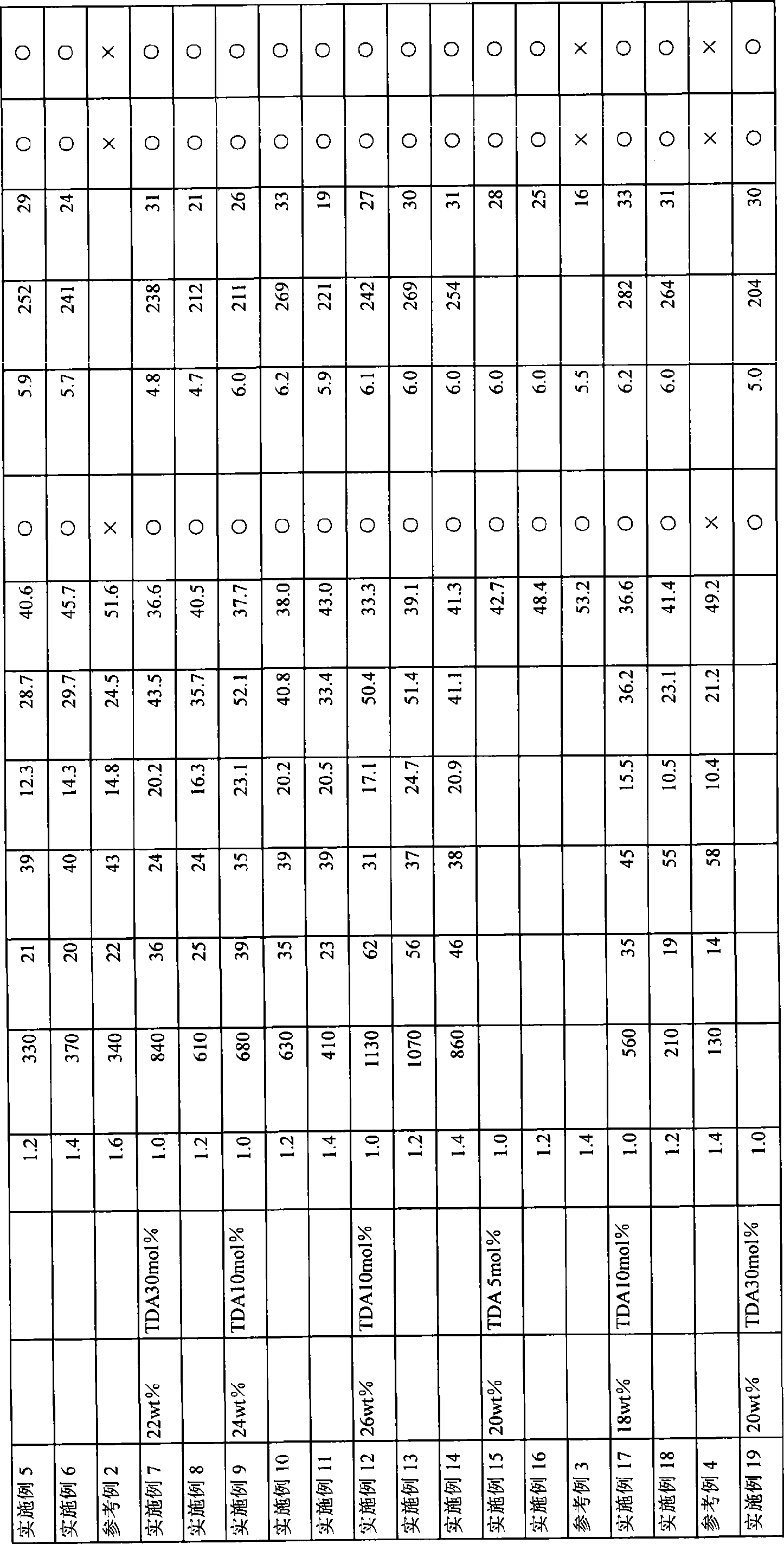

[0139] (Examples 1-19, Reference Examples 1-4)

[0140] As the aromatic diamine component, in addition to p-phenylenediamine, 2,4-toluenediamine (TDA) was used in the amount shown in Table 1, and the solid content concentration and / or preparation of the polyimide precursor solution Except having changed the film velocity as shown in Table 1, it carried out similarly to the comparative example 1, and obtained the polyimide film.

[0141] In the table, the film forming speed is represented by the multiplication rate relative to the film forming speed of Comparative Example 1. Similarly to Comparative Examples 2 to 12, the heating time in each step of casting and aging shown in Comparative Example 1 was shortened equally in order to make the film forming rate the multiplication rate shown in the table. In addition, the usage-amount of 2, 4- toluenediamine is shown by the ratio with respect to the whole aromatic diamine component (PPD+TDA).

[0142] Table 1 shows the physical pr...

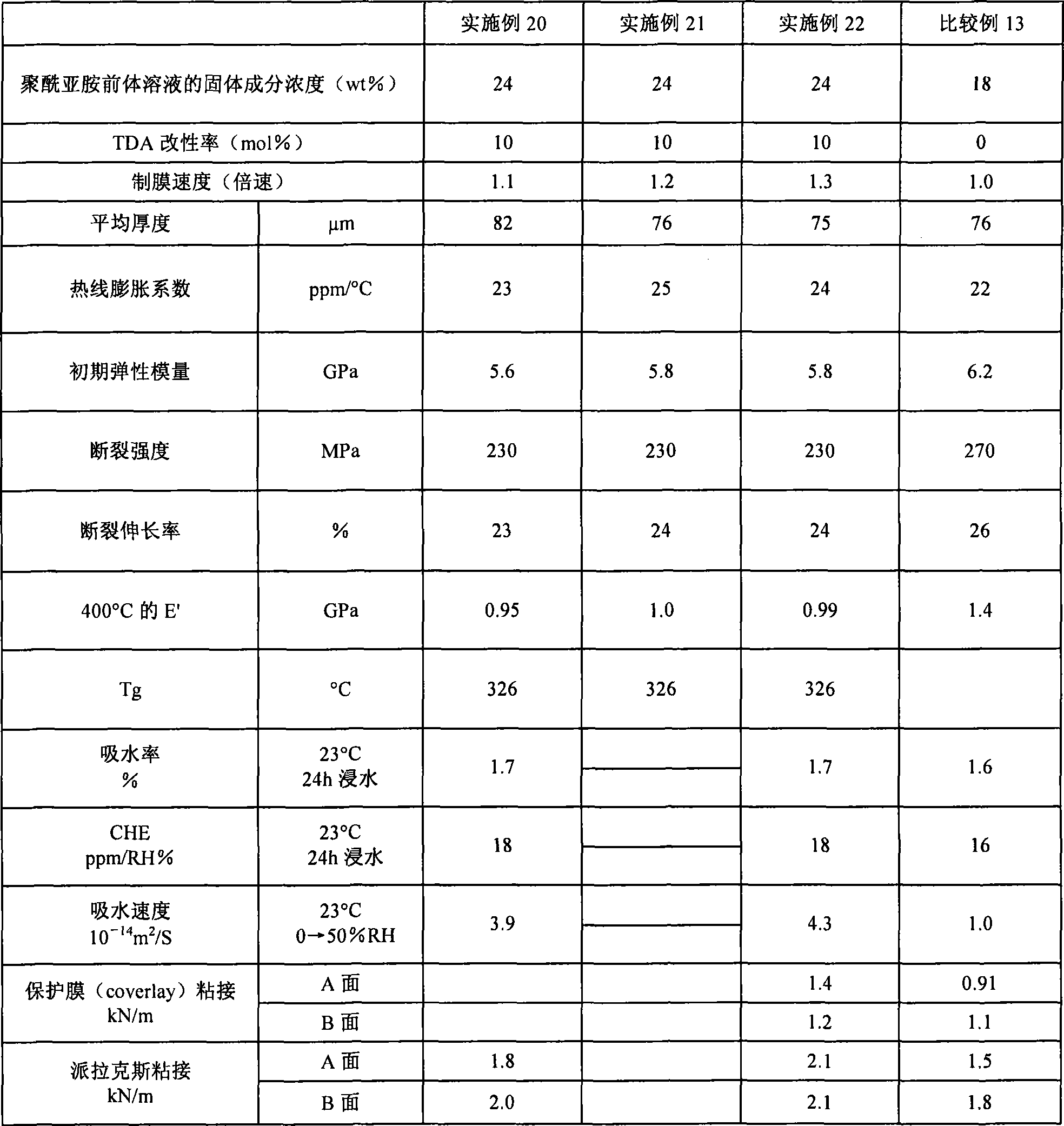

Embodiment 20~22

[0152] Carry out in the same manner as Examples 9-11, prepare the polyimide precursor solution composition that the solid content concentration is 24% by mass, introduce 10 mol% TDA, and cast it continuously from the gap of the T die head metal type. Films are formed by extrusion on a smooth metal support in a drying oven. Next, the film was heated at 155° C. for a predetermined time, and then peeled from the support to obtain a self-supporting film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com