Method for producing peanut cheese and peanut yoghurt

A production method and technology for peanut milk, which are applied in the field of process production of cheese and yogurt, can solve the problems of low addition amount of peanut milk and the like, and achieve the effect of improving the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

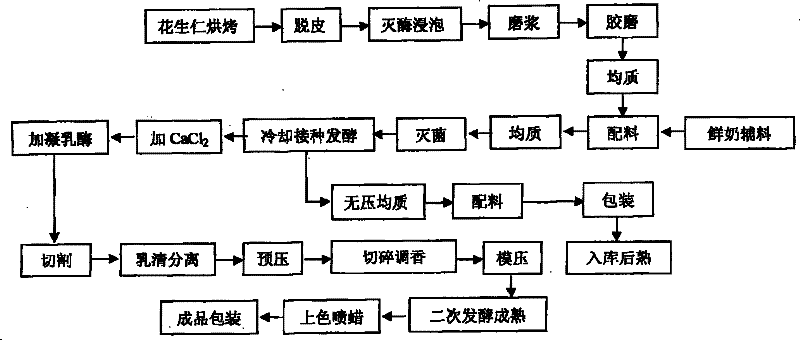

[0045] Embodiment 1: the production method of peanut cheese

[0046] Accurately weigh 10Kg of peeled peanut kernels, soak them in about 3 times of water and wash them with NaHCO 3Adjust the pH of the soaking water to 8.5-9.0 overnight, and wash it twice with water in the morning of the next day; refine the pulp according to 1:6 of the dry weight of peanut kernels, that is, 60Kg hot water (90°C); use 40Kg water for the first time, and use it for the second time. 20Kg of water, grind the peanut dregs again, combine the second slurry and pour it into the colloid mill for fine grinding once, the formula is as follows:

[0047] Peanut milk 80% sucrose 5.5%

[0048] Fermentation Accelerator 2.5% Milk 12%

[0049] The fermentation accelerator is that the weight ratio of sodium citrate, sodium tripolyphosphate and glucose is 1:1:2;

[0050] Pour the auxiliary material granulated sugar, accelerator and milk into the peanut milk to mix and stir to dissolve. At this time, the temperat...

Embodiment 2

[0054] Embodiment 2: the production of peanut yoghurt

[0055] The milk-making process of yogurt, the pretreatment of peanut kernels and peanut milk are the same as implementation 1.

[0056] Season according to the following recipe

[0057] Peanut milk 85% sucrose 6%

[0058] Fermentation Accelerator 3% Fermentation Accelerator 2.5%

[0059] 0.35% stabilizer, 3.15% milk, appropriate amount of spices

[0060] After the material liquid has been homogenized twice, heat it up at 85°C for 15 minutes in a hot and cold cylinder or sterilize it at ultra-high temperature (135°C for 3 to 4 seconds), put it into the fermentation tank to adjust the temperature at 45°C, stir and add 3% fermentation strain, the strain is Bulgaria Lactobacillus and Streptococcus thermophilus are 1:2 mixed species, fermented for 2.5 to 3.0 hours, acidity 80 to 90°T, pH 4.6 to 4.4, naturally formed into curd, through thick slurry pump or rotor pump, into the packaging machine In the barrel, the eight cups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com