Combustion synthesis apparatus for fullerenes

A combustion synthesis, fullerene technology, applied in the C70 and fullerene derivatives and other carbon cluster devices to prepare C60 field, can solve the problems of safety hazards, complex diffusion devices, synthesis ability defects, etc., to achieve operational flexibility High performance, good safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

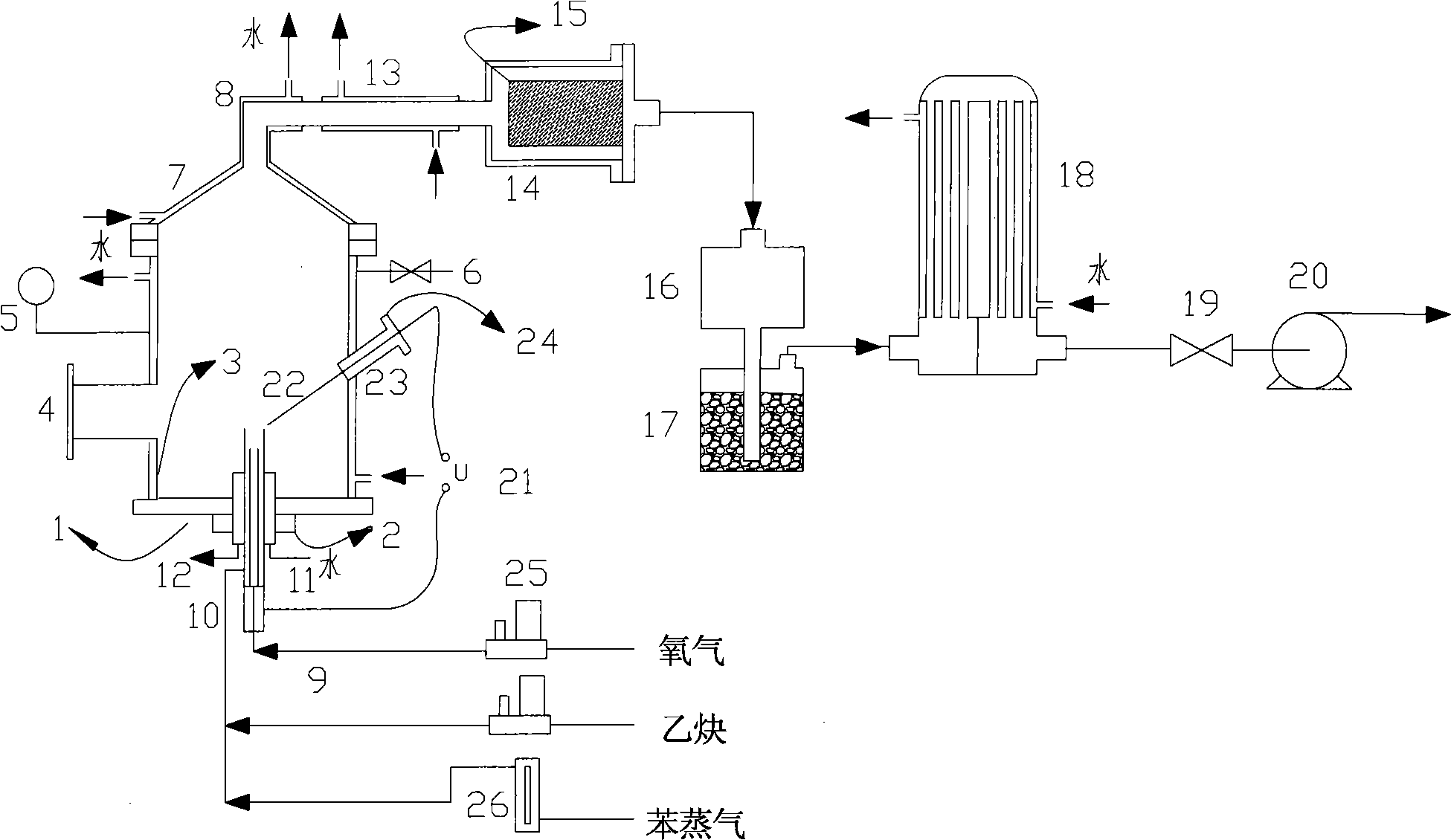

[0028] see figure 1 , The present invention is equipped with a combustion furnace, a combustion nozzle, a sleeve condenser, a canister, a liquid filter, a heat exchanger, a vacuum pump, a vacuum regulation system, an ignition system, a gas supply and control system, a vacuum test and display device.

[0029]The combustion furnace is the main part of the embodiment of the present invention, and consists of a chassis 1, a furnace body 3 and a furnace cover 7 sealed by an O-ring from bottom to top. Chassis 1 is a stainless steel disc with a round hole in the middle, and the length of the circular passage is increased by welding a round pipe 2 with the same inner diameter as the round hole. There is a groove in the passage, which is fixed and sealed by a rubber gasket and passes through it. combustion nozzle. The height design of the furnace body 3 shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com