Plant source herb residual machine-made carbon and method of processing the same

A technology of plant-derived medicine and mechanism charcoal, which is applied in the fields of biofuel, waste fuel, petroleum industry, etc., can solve the problems of high cost, insufficient number of raw material sources, and high cost of mechanism charcoal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

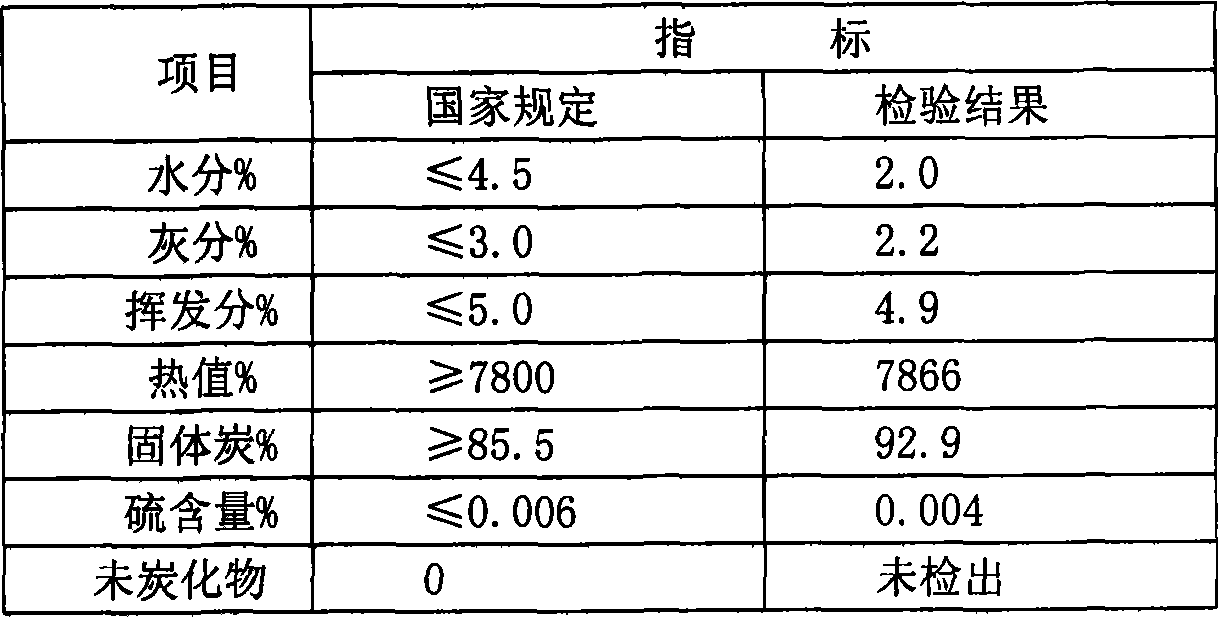

Image

Examples

Embodiment Construction

[0016] Non-limiting examples are described as follows:

[0017] 1. Take 60kg of naturally dried plant-derived medicinal residues (including the peel and shell of camellia oleifera and hickory), take 25kg of pine branches, 5kg of bamboo chips, and 10kg of mulberry branches, and break them into debris. cm 2 Extruded into billets under pressure. The required temperature is taken from the waste heat of the carbonization furnace on the one hand (increasing the ambient temperature is conducive to drying), and on the other hand from the compression heat of the mixture. The billet has a square cross-section, a specification of 5.0 x 5.0 x 60cm, a through hole in the center (with an inner diameter of 1.5-2.0cm), and is dried and dehydrated to a moisture content of 14%.

[0018] Stack the billets into the vertical carbonization furnace with the through holes aligned upwards. Place a igniter on the top of the stacked billets, ignite the billets to spontaneously ignite, close the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com