Industrialized biological degumming technique for kenaf bast fiber

A biological degumming and industrialization technology, applied in the direction of bacterial retting, etc., can solve the problems of long degumming cycle, unstable fiber output and quality, etc., and achieve the effect of shortening the degumming cycle, stable product quality and small site occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

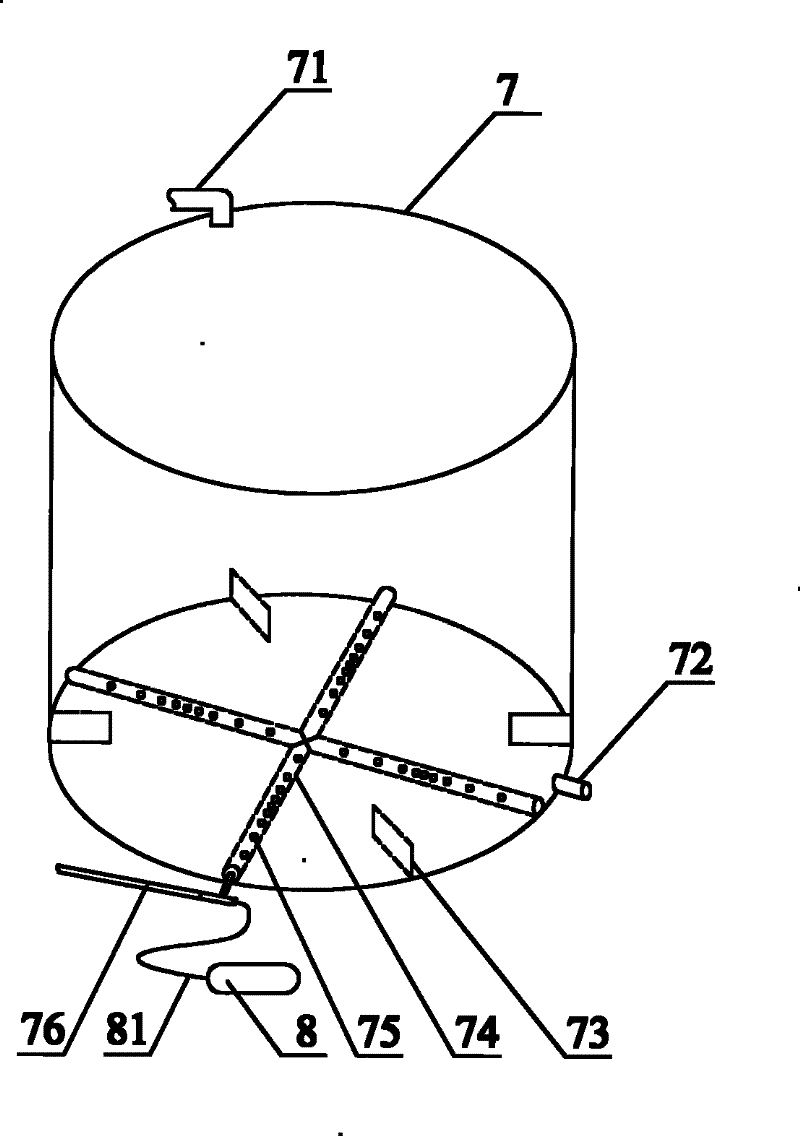

[0046] The kenaf bast 400kg of the different varieties that the farmer buys from Zhejiang, Anhui, Henan and other kenaf production areas and places of production is carried out biological degumming, specifically comprises the following steps (see Figure 4 Process flow shown):

[0047] (1) Pretreatment of kenaf bast: the above-mentioned kenaf fiber unbundled, straightened and divided into hemp handles, each with a quality of 1kg, rolling the above-mentioned kenaf bast hemp handles; rolling When the kenaf bast is loose and the kenaf fibers are not damaged (easy to be infected by microorganisms), stop rolling, and then shake off most of the sundries (silt, hemp bones, petioles) attached to the kenaf bast , young shoots, miscellaneous bacteria and decayed tissues, etc.);

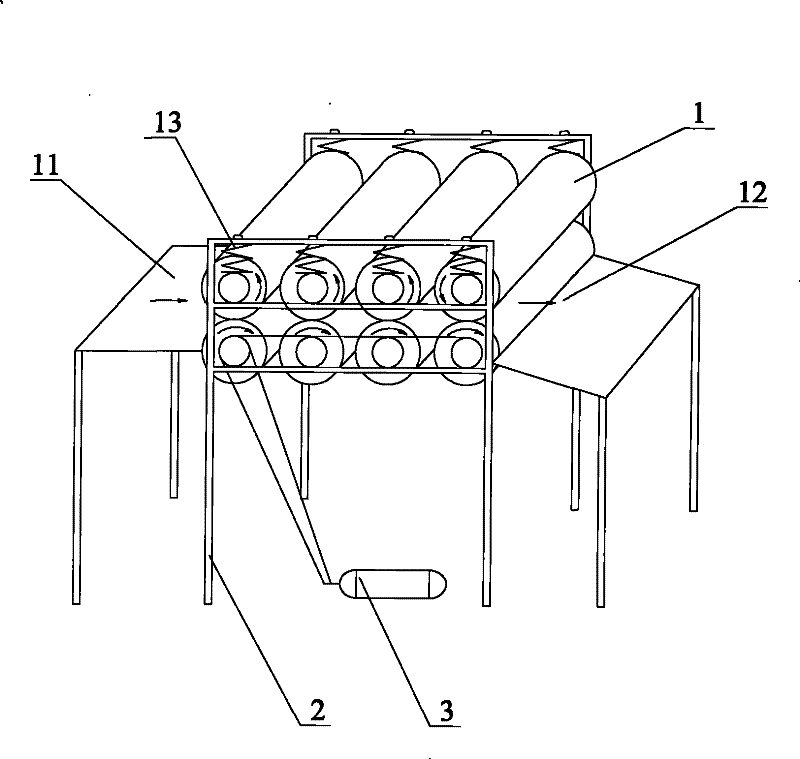

[0048] The above-mentioned rolling process can be used as figure 1 The roller rolling device shown is processed, including roller 1 (length is 240-480mm, diameter is 120-240mm), machine base 2 and driving dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com