Liquid sustained-release acid breaker

A slow-release acid gel breaker and liquid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of oil well scrapping, large impact on construction effect, poor operability, etc., and achieve small impact on colloid performance, Improvement of construction operability and effectiveness, slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1, a liquid slow-release acid breaker, is prepared by putting 100 g of dimethyl malonate and 400 g of petroleum ether into a 1000 mL flask at room temperature and stirring evenly. This product is added to 50 kg of water-based jelly fracturing fluid, stirred evenly, and pumped downhole together with the fracturing fluid.

[0013] Hydrolysis of ethyl formate, its chemical formula:

[0014] CHOOC 2 h 5 O+H 2 O→HCOOH+C 2 h 5 Oh

Embodiment 2

[0015] Embodiment 2, a kind of liquid sustained-release acid breaker, is at normal temperature, puts 100g of diethyl oxalate, 300g of butyl acetate into the flask of 1000mL and stirs uniformly to make. This product is added to 10 kg of water-based jelly fracturing fluid, stirred evenly, and pumped downhole together with the fracturing fluid.

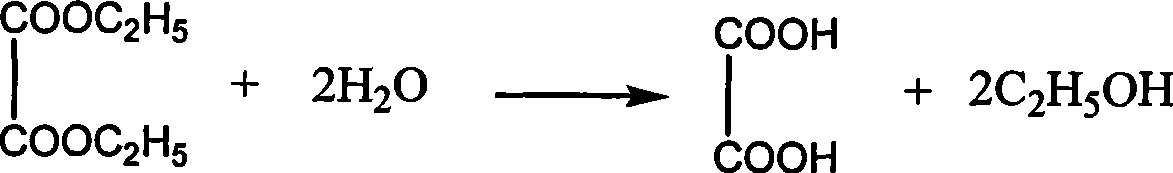

[0016] Hydrolysis of diethyl oxalate, its chemical formula:

[0017]

Embodiment 3

[0018] Embodiment 3, a kind of liquid sustained-release acid breaker, is at normal temperature, puts 100g of ethyl formate, 500g of butyl acetate into the flask of 1000mL and stirs uniformly to make. This product is added to 30 kg of water-based jelly fracturing fluid, stirred evenly, and pumped downhole together with the fracturing fluid.

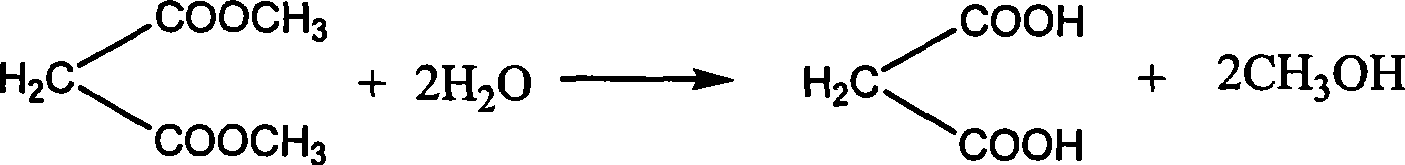

[0019] Dimethyl malonate is hydrolyzed, and its chemical formula is:

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com