Fe-based bulk amorphous alloy material and method of producing the same

A technology of amorphous alloy and bulk, which is applied in the field of iron-based bulk amorphous alloy material and its preparation, can solve the problems that engineering materials cannot be widely used, and achieve the effects of high hardness, strong glass forming ability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

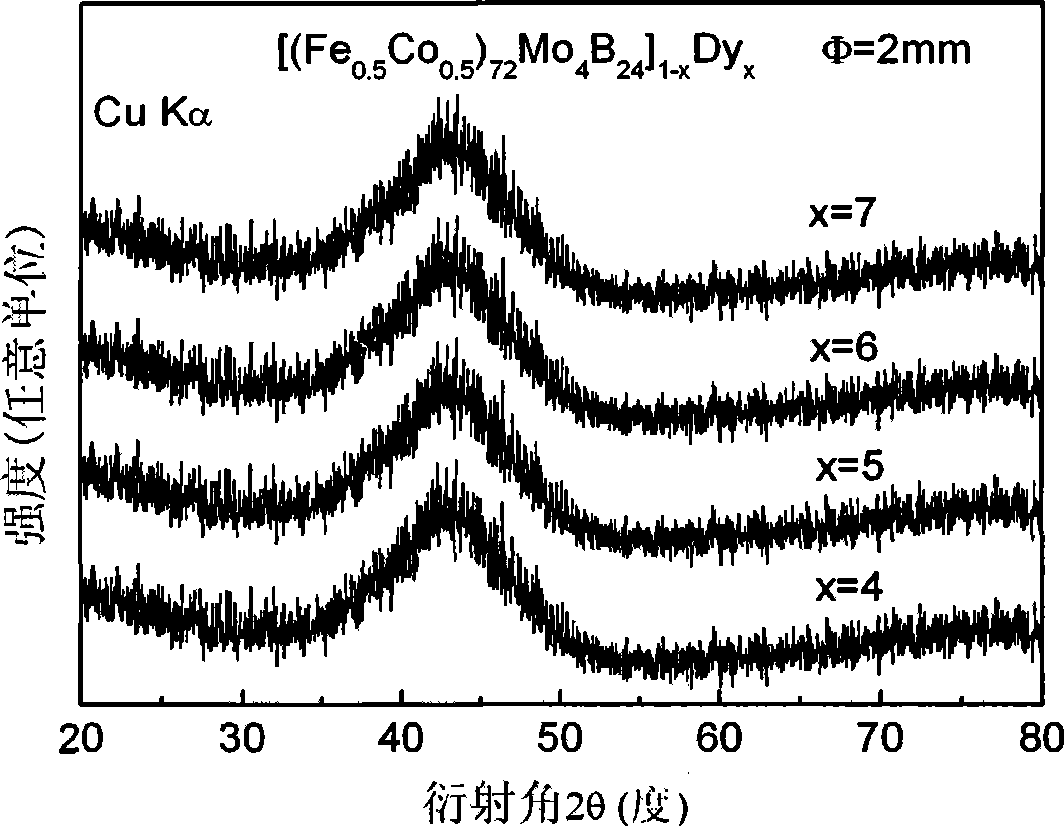

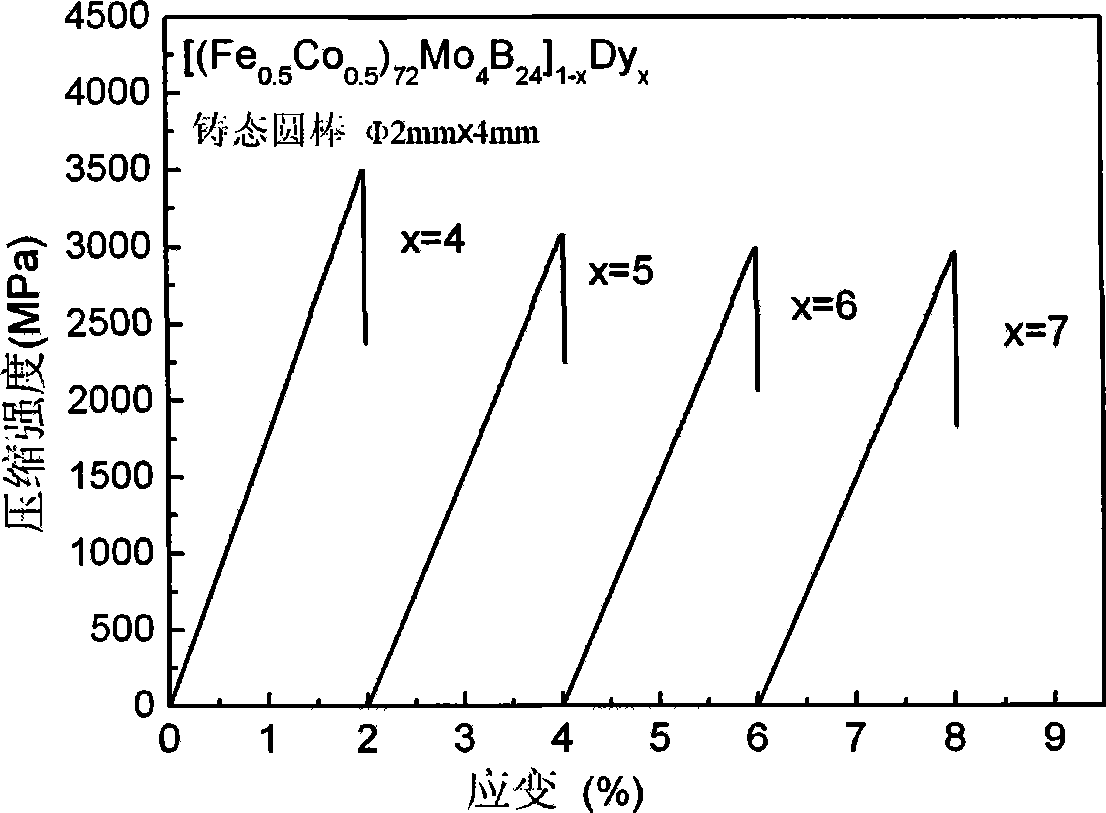

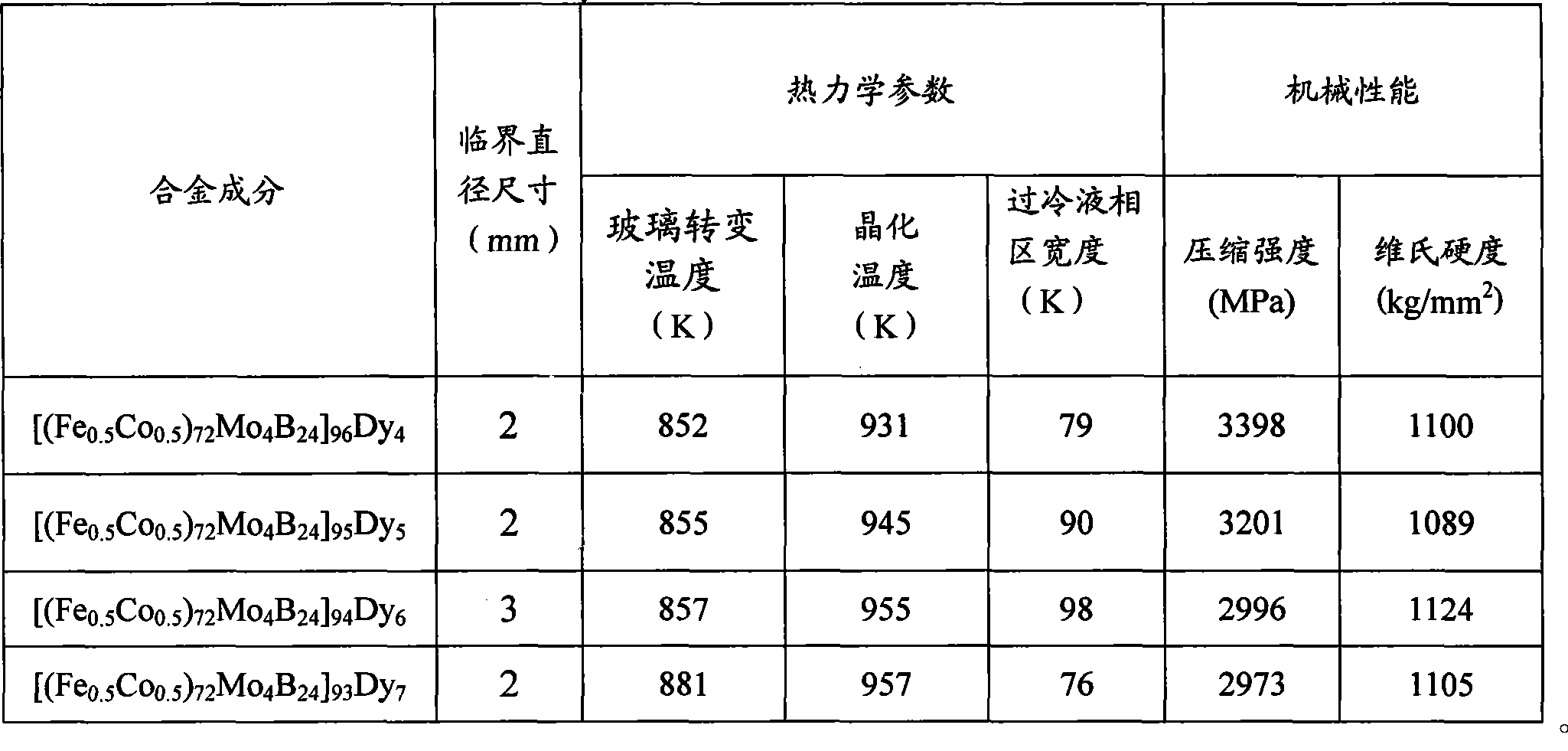

[0016] Embodiment 1: preparation [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 96 Dy 4 Amorphous Alloy Rods

[0017] Fe, Co, Mo, B and Dy elements according to [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 96 Dy 4 After the alloy atomic percentage is converted into mass percentage, accurately weigh Fe with a purity of 99.6%, Co with a purity of 99.9%, Mo with a purity of 99.8%, Dy with a purity of 99.9% and FeB alloy, and put the quartz in the induction furnace tube, to be evacuated to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting for 9 times to obtain evenly mixed [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 96 Dy 4 Master alloy ingots. will get [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 96 Dy 4 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol. Then put it into a quartz tube with an open lower end and a hole diameter of 0.5mm, and draw a vacuum ...

Embodiment 2

[0018] Embodiment 2: preparation [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 95 Dy 5 Amorphous Alloy Rods

[0019] Fe, Co, Mo, B and Dy elements according to [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 95 Dy 5After the alloy atomic percentage is converted into mass percentage, accurately weigh Fe with a purity of 99.6%, Co with a purity of 99.9%, Mo with a purity of 99.8%, Dy with a purity of 99.9% and FeB alloy, and put the quartz in the induction furnace tube. To be vacuumed to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting 10 times to obtain a well-mixed [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 95 Dy 5 Master alloy ingots. will get [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 95 Dy 5 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol. Then put it into a quartz tube with an open lower end and a hole diameter of 0.4 mm, and draw a vacuum to ...

Embodiment 3

[0020] Embodiment 3: preparation [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 94 Dy 6 Amorphous Alloy Rods

[0021] Fe, Co, Mo, B and Dy elements according to [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 94 Dy 6 After the alloy atomic percentage is converted into mass percentage, accurately weigh Fe with a purity of 99.6%, Co with a purity of 99.9%, Mo with a purity of 99.8%, Dy with a purity of 99.9% and FeB alloy, and put the quartz in the induction furnace tube. To be vacuumed to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting 6 times to obtain evenly mixed [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 94 Dy 6 Master alloy ingots. will get [(Fe 0.5 co 0.5 ) 72 Mo 4 B 24 ] 94 Dy 6 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol. Then put it into a quartz tube with an open lower end and a hole diameter of 0.4 mm, and draw a vacuum to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com