Nickel-free Zr-based bulk amorphous alloy with excellent biocompatibility as well as preparation method and application of nickel-free Zr-based bulk amorphous alloy

A biocompatible, amorphous alloy technology, applied in the field of nickel-free Zr-based bulk amorphous alloy and its preparation, can solve problems such as damage to liver and lung function, decline in animal growth rate and reproductive ability, and carcinogenicity. The effect of low, low elastic modulus, high manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is copper mold spray casting (Zr 53.6 Al 18.6 co 27.8 ) 0.99 Ag 1 (at.%) Amorphous alloy rod.

[0038] The preparation method of this embodiment is as follows: first, the industrial-grade raw materials Zr, Al, Co, and Ag are prepared according to atomic percentage, and smelted under the protection of argon to obtain a master alloy ingot. In order to ensure the quality, it is necessary to use pure Ti as an oxygen absorber to remove residual oxygen in the furnace, and the alloy ingots are smelted at least four times. Then the alloy ingot was mechanically crushed, and spray casting equipment was used to heat and melt the broken master alloy ingot, and sprayed with argon gas into a copper mold with a diameter of 4mm for cooling (4mm is the maximum forming ability of this component). The spray-casting temperature is 1000°C, and the vacuum before spray-casting is 10 -2 Pa.

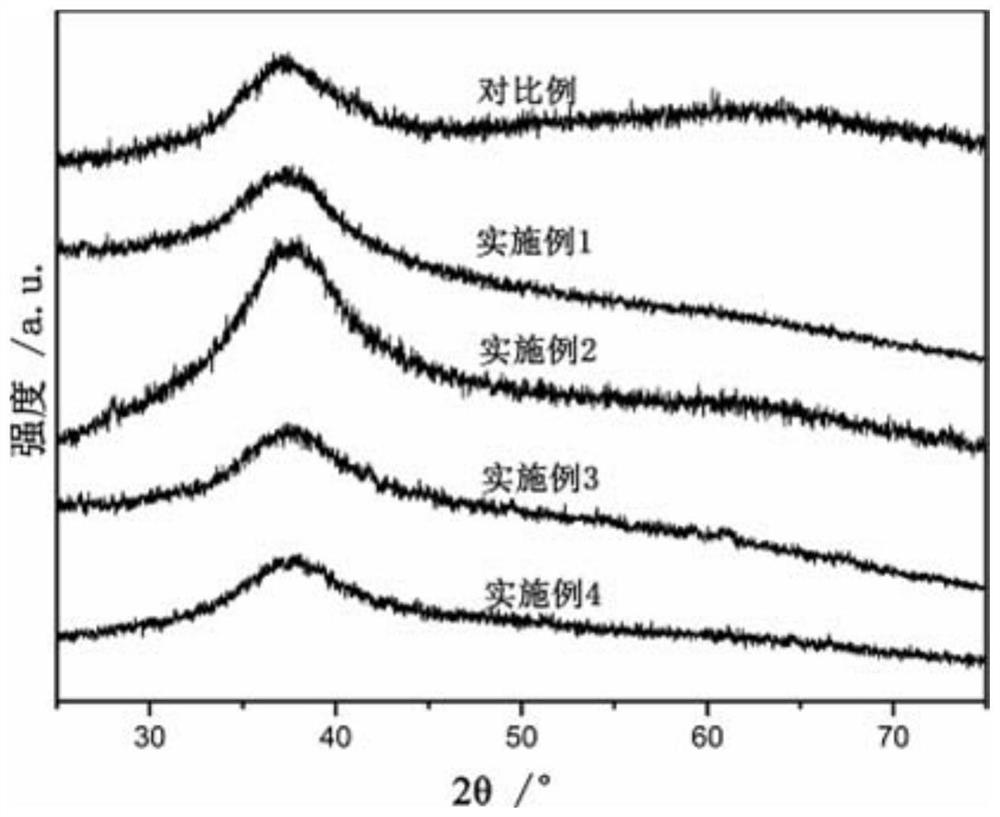

[0039] Such as figure 1 As shown, the X-ray diffraction results show that the ...

Embodiment 2

[0042] This embodiment is copper mold spray casting (Zr 53.6 Al 18.6 co 27.8 ) 0.98 Ag 2 (at.%) alloy bar.

[0043] The ingredients and master alloy smelting method of this embodiment are the same as in Example 1. In the casting stage, use spray casting equipment to heat and melt the master alloy fragments, and spray them with argon into a 6mm copper mold for cooling (6mm is maximum forming capacity of the component). Among them, the spray casting heating temperature is 1000°C, and the vacuum degree before spray casting is 10 -2 Pa.

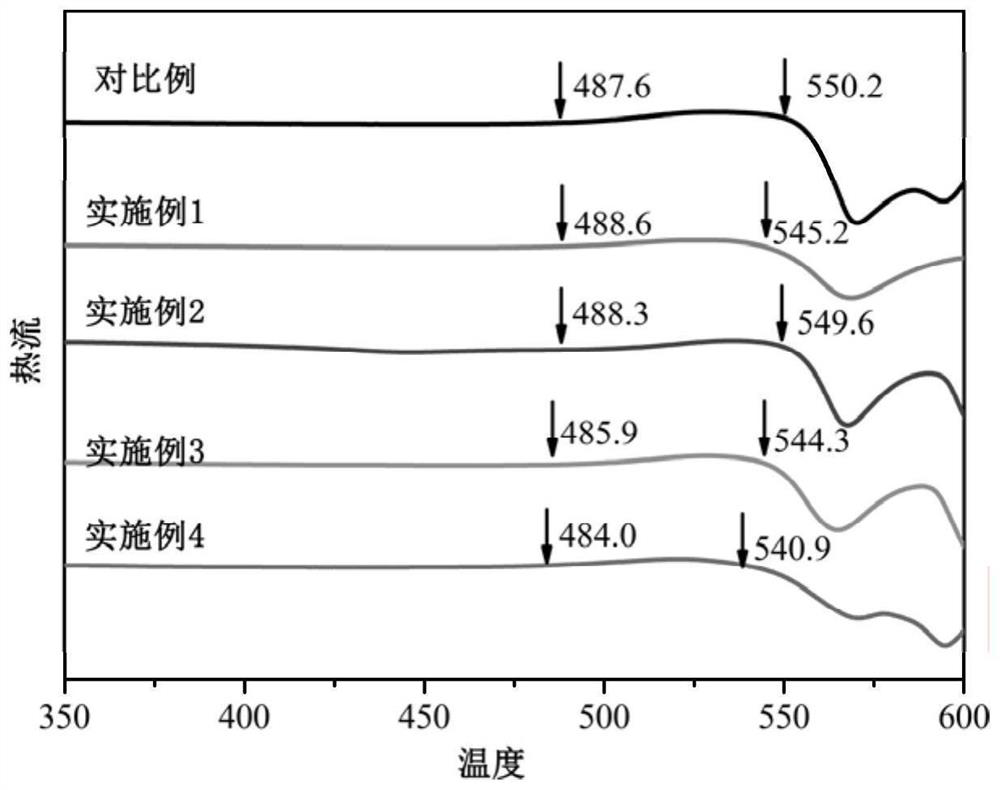

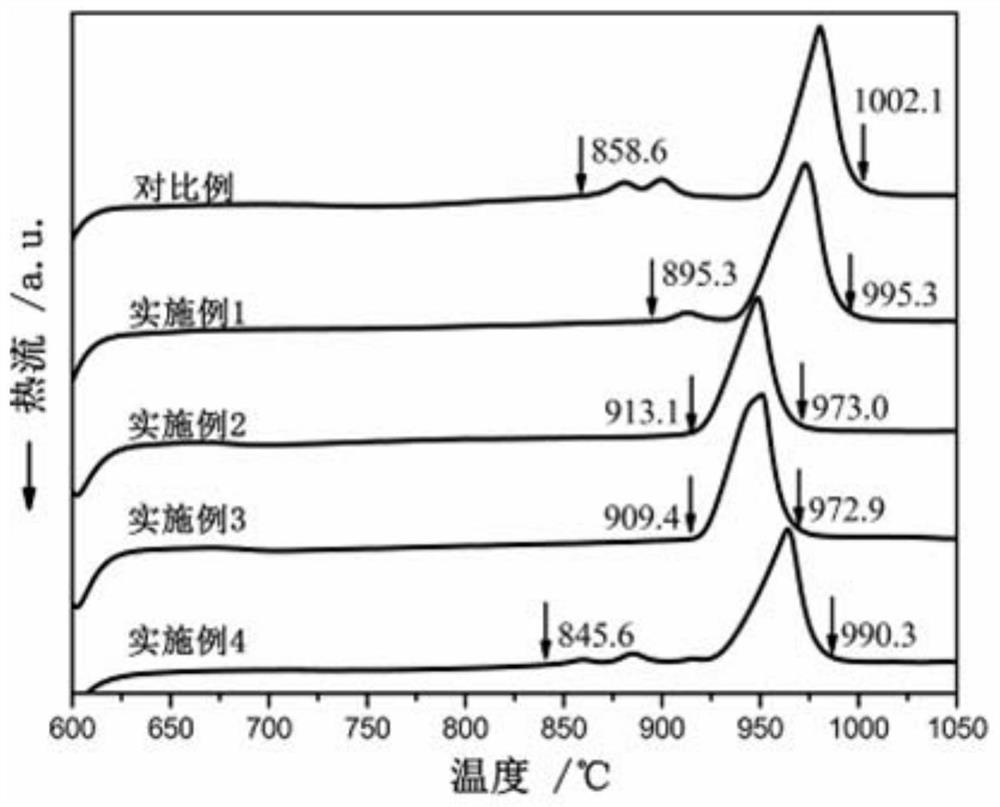

[0044] Such as figure 1 As shown, the X-ray diffraction results show that the 6mm rod provided by this comparative example is a pure amorphous structure. Such as Figure 2-3 As shown, the glass transition temperature T of the amorphous alloy g : 488.3, supercooled liquid region △T: 62.7℃, initial melting temperature T m : 913.1℃, liquidus temperature T l : 973.0°C, T l -T m : 59.9°C.

[0045] Use the same process to spray-cast am...

Embodiment 3

[0046] Figure 7 is the OD value of the activity of MC3T3-E1 cells cultured on the amorphous alloy and TC4 in this embodiment. For MC3T3-E1 cells incubated for 24 hours, the OD value of the amorphous alloy was slightly higher than that of the TC4 alloy. After 48 hours, the difference in OD values between the amorphous alloy and TC4 increases. After 72 hours, the OD value of the amorphous alloy was significantly higher than that of TC4. Therefore, compared with cells cultured on TC4, cells cultured on amorphous alloys have higher survival rate and proliferation ability, showing good biocompatibility. Embodiment 3: the present embodiment is copper mold injection casting (Zr 53.6 Al 18.6 co 27.8 )Ag 3 Alloy bars.

[0047] Example 3:

[0048] This embodiment is copper mold spray casting (Zr 53.6 Al 18.6 co 27.8 ) 0.97 Ag 3 (at.%) alloy bar.

[0049] The ingredients and master alloy smelting method of this embodiment are the same as in Example 1. In the casting stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com