Gas magnetic mixing suspension type plane motor with six freedom degrees

A planar motor and gas-magnetic hybrid technology, which is applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of not dynamically adjusting the size of the air flotation air gap, affecting the positioning accuracy of the planar motor, and low precision requirements, etc., to achieve processing The effect of low difficulty, reduced mass and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

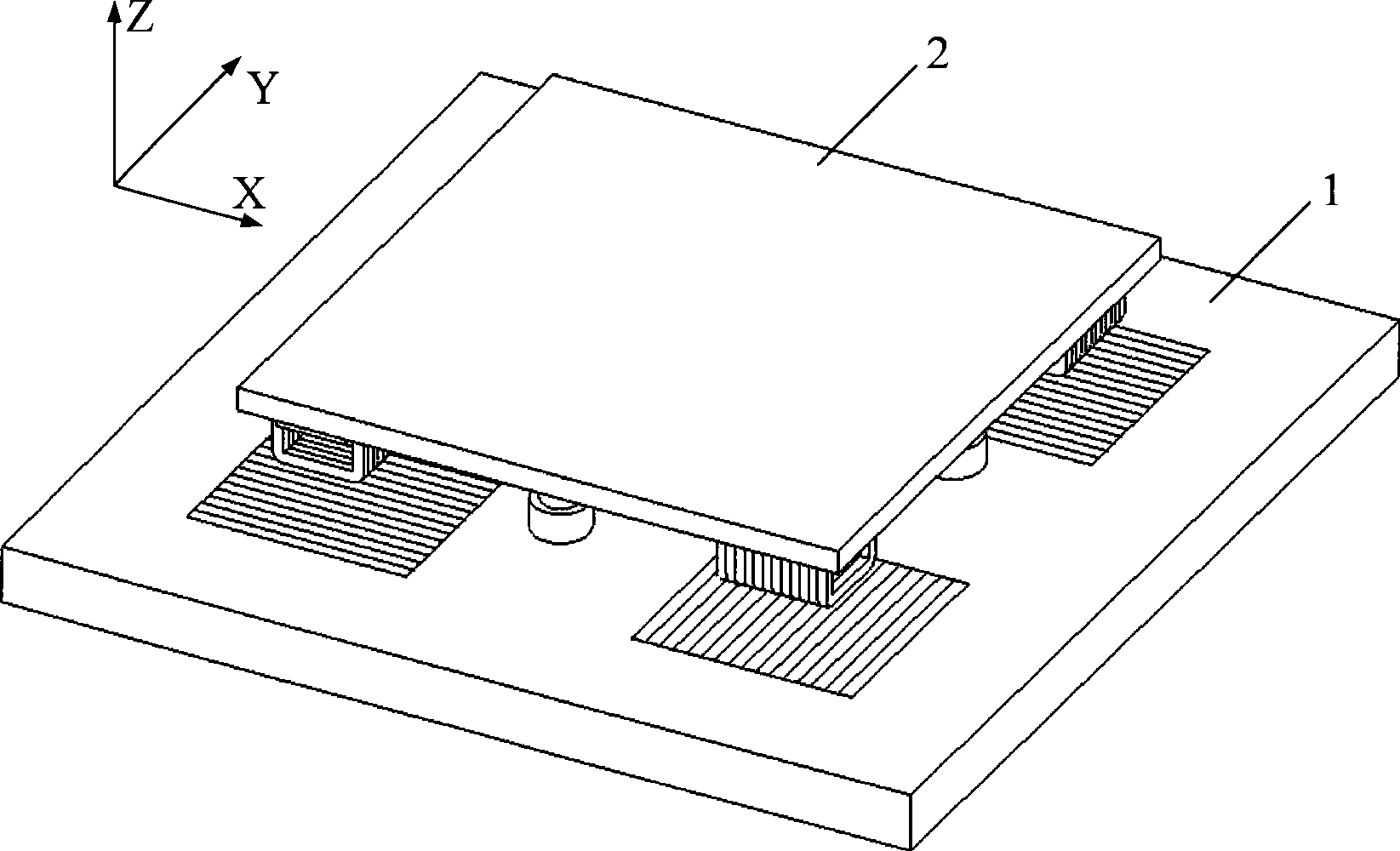

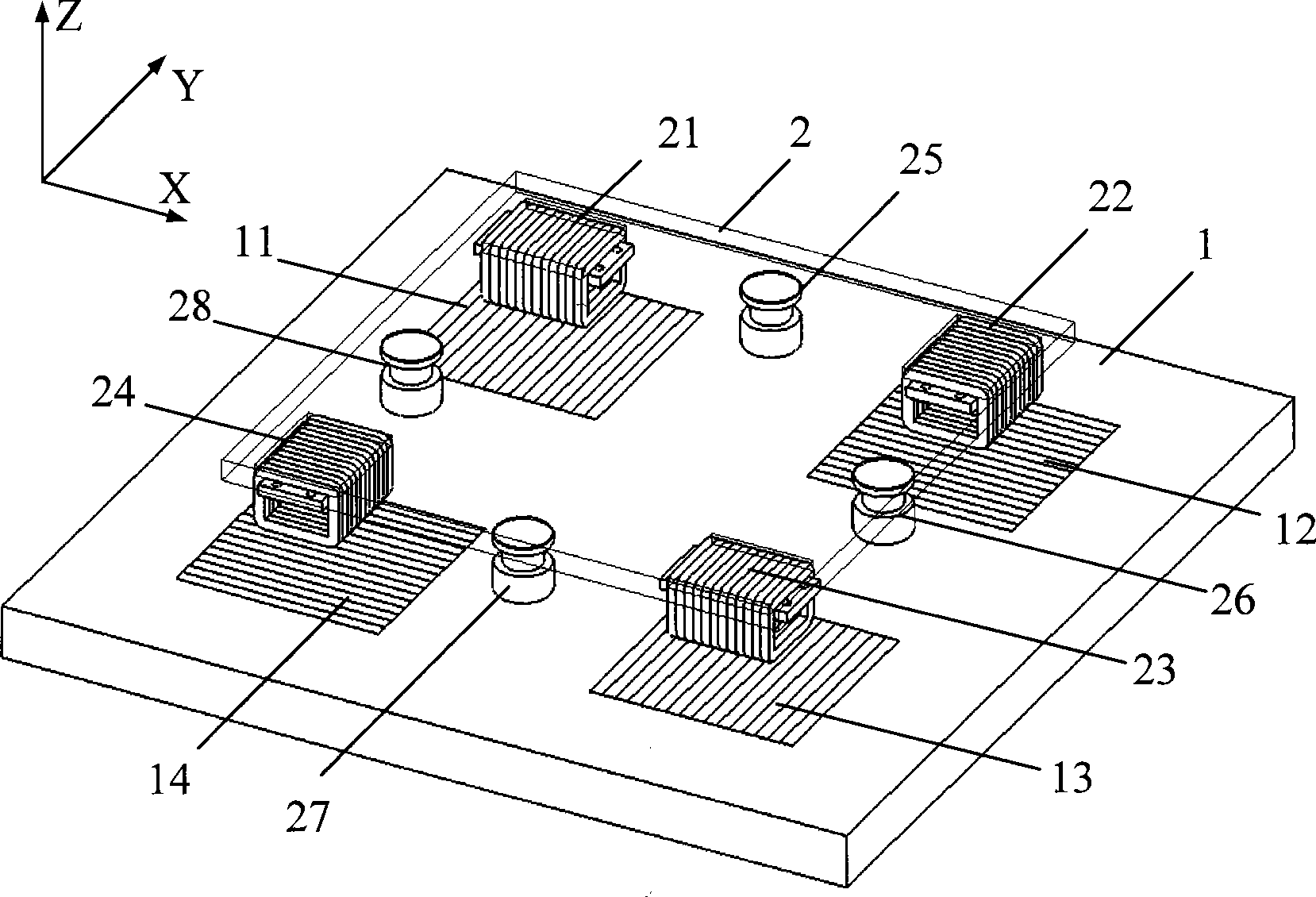

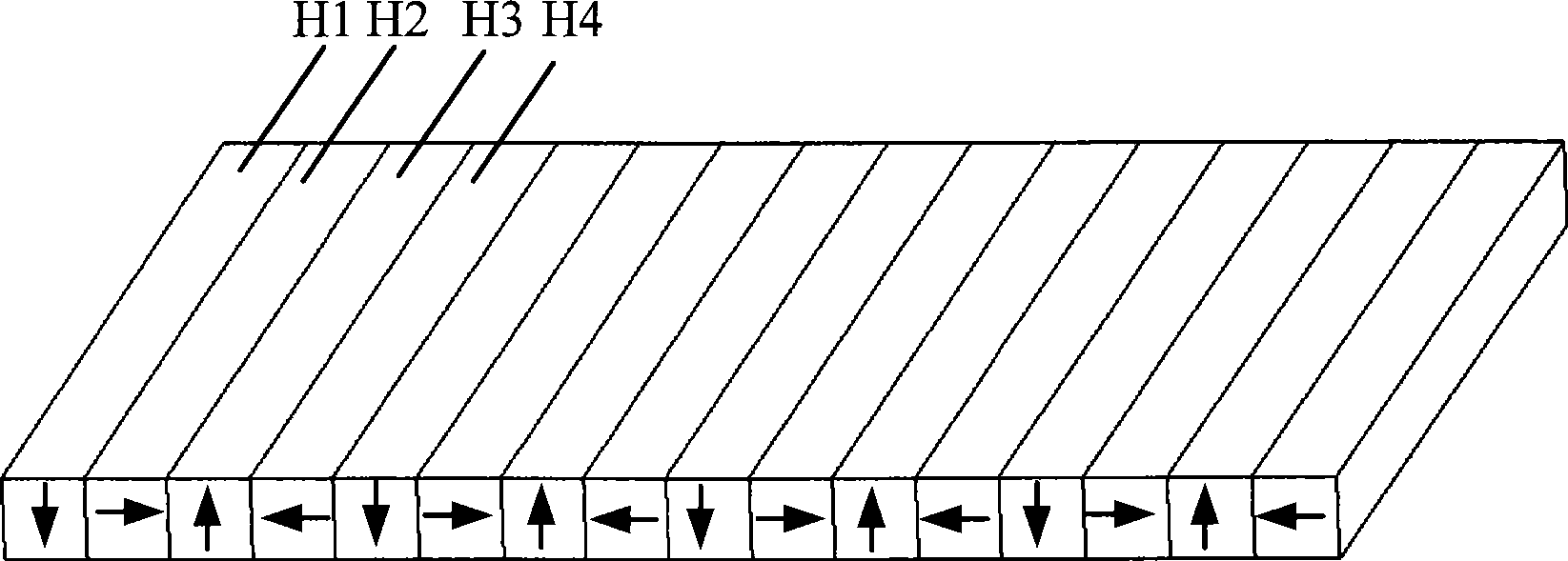

[0040] see figure 1 , figure 2 , the present invention adopts a single mover structure in which the mover platform is a single-layer structure, including a stator base 1 placed along the horizontal XY plane and a mover base 2 floating on the stator base 1 and parallel to the stator base 1 . The four corners of the upper surface of the stator base 1 are respectively embedded with a first Halbach permanent magnet array 11, a second Halbach permanent magnet array 12, a third Halbach permanent magnet array 13, and a fourth Halbach permanent magnet array 14, wherein the first Halbach permanent magnet array 11 The wavelength direction of the third Halbach permanent magnet array 13 is in the same direction as the X axis, and the wavelength direction of the second Halbach permanent magnet array 12 and the fourth Halbach per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com