Device for clearing and cutting fixed length of clad tube

A technology of cleaning device and cladding tube, which is applied in metal processing and other directions, can solve the problems that it is difficult to guarantee the processing accuracy and processing efficiency of components, the processing accuracy and cleanliness of components cannot be guaranteed, and the requirements of assembly line operation cannot be met, so as to achieve the convenience of replacement and purchase , easy maintenance, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

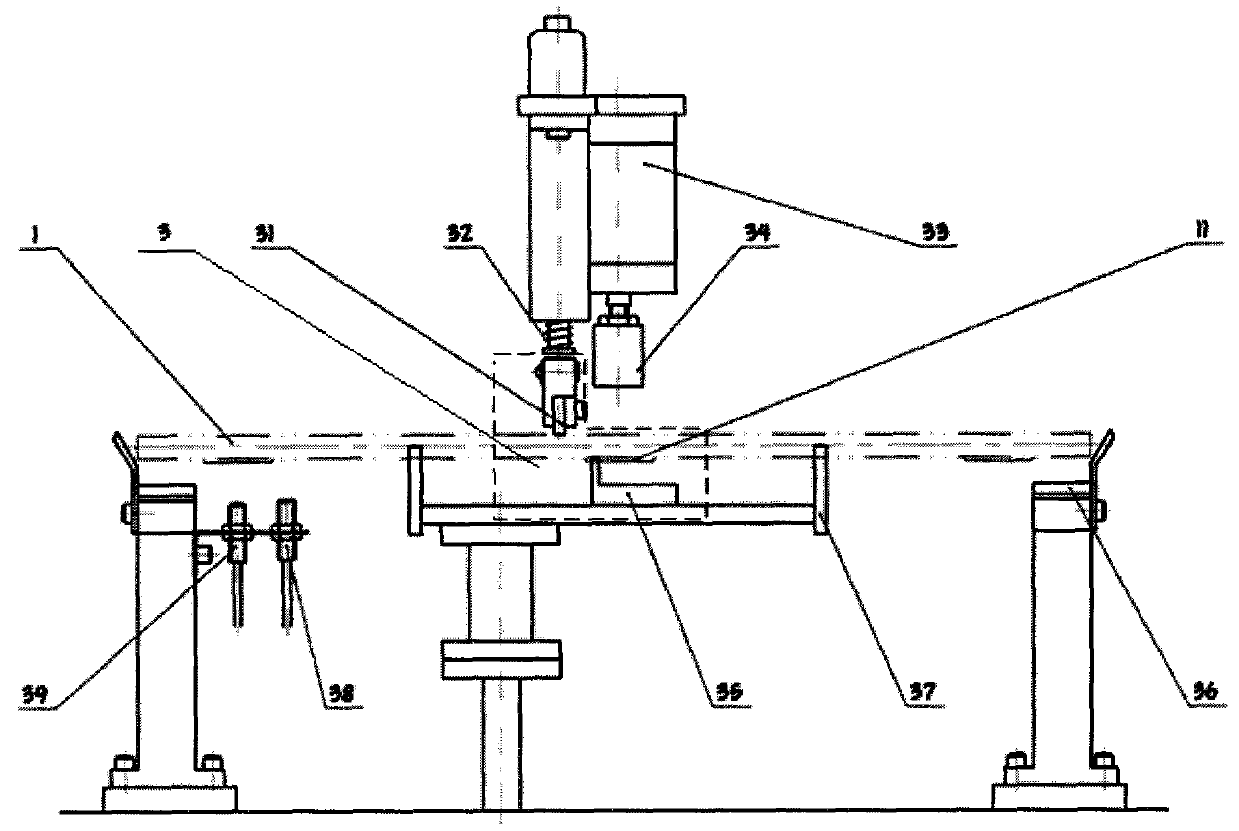

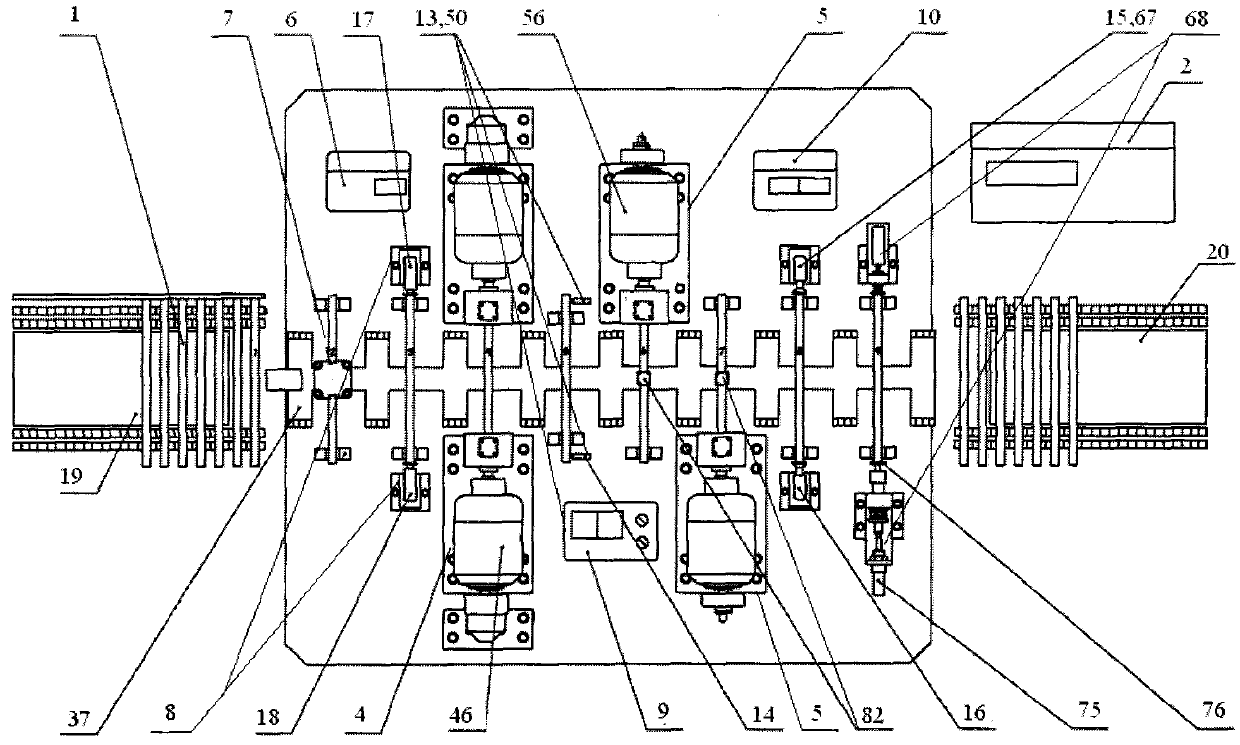

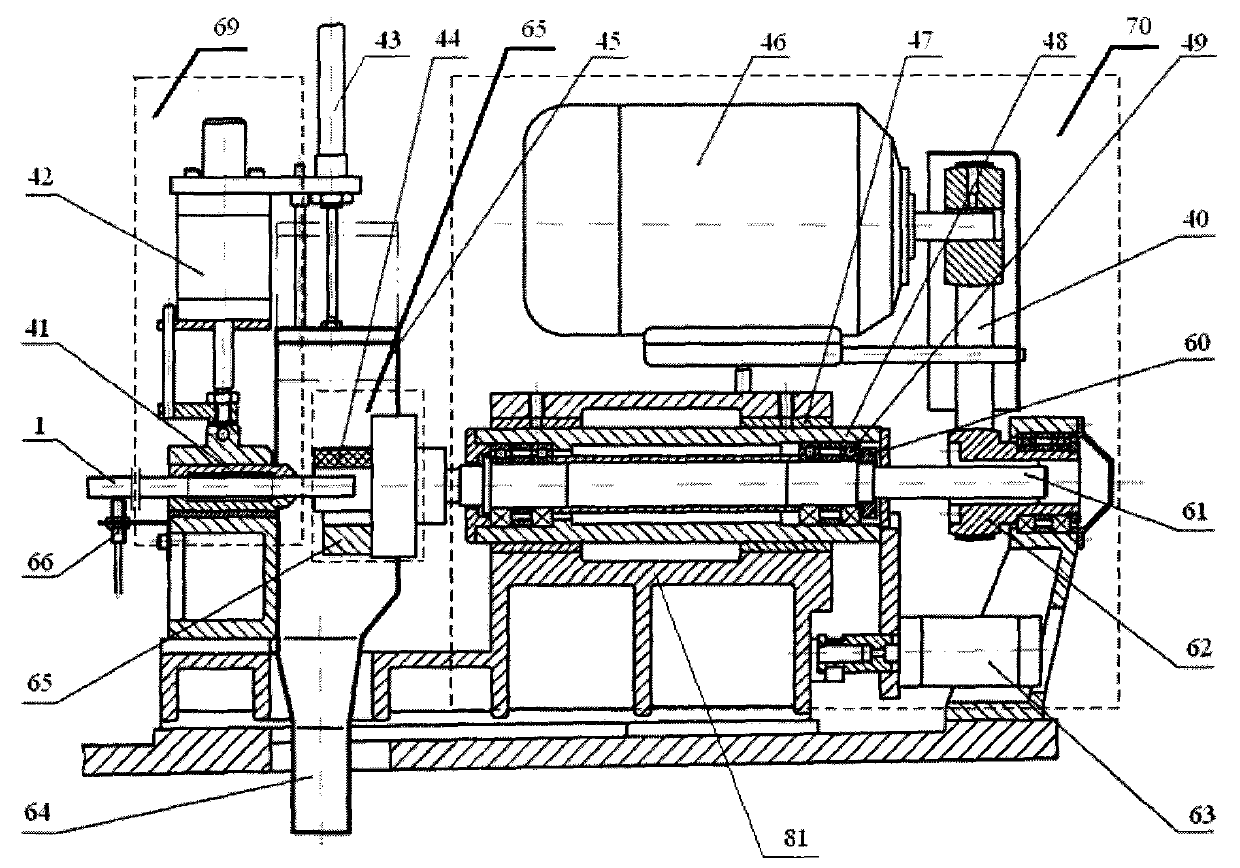

[0019] like figure 1 A cladding pipe cleaning and cutting length-fixing device is shown, which includes a feeding rack 19, a feeding rack 37 and a feeding rack 20, and a cleaning device 4 and a cutting and length-fixing device 5 are successively installed along the feeding rack 37. Between the frame 19 and the cleaning device 4, a pipe straightening device 7 and a graphite coating detection device 8 are installed successively, and a cleaning quality detection device 50 is provided between the cleaning device 4 and the cutting and length fixing device 5; the cutting and length fixing device 5 is provided with Two, are installed on the station of feeding rack 37 both sides successively, between cleaning device 4 and unloading rack 20, beveled detection device 67 and length measuring device 68 are installed successively.

[0020] The graphite coating detection device 8 comprises a coating detection transmitter 17 and a coating detection receiver 18 installed on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com