Method of processing high concentration organic wastewater

A technology of organic wastewater and treatment method, which is applied in the fields of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Handling complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

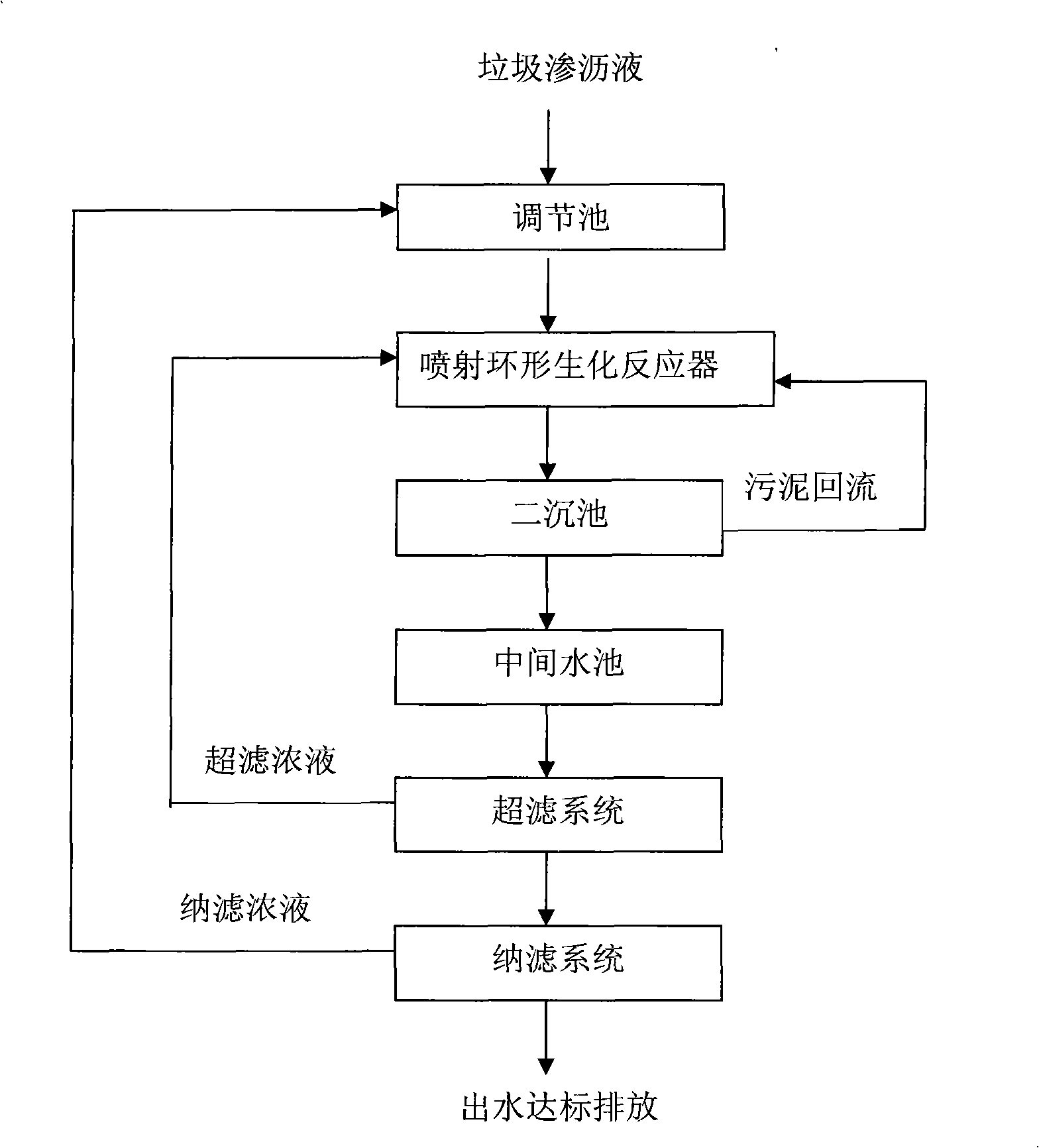

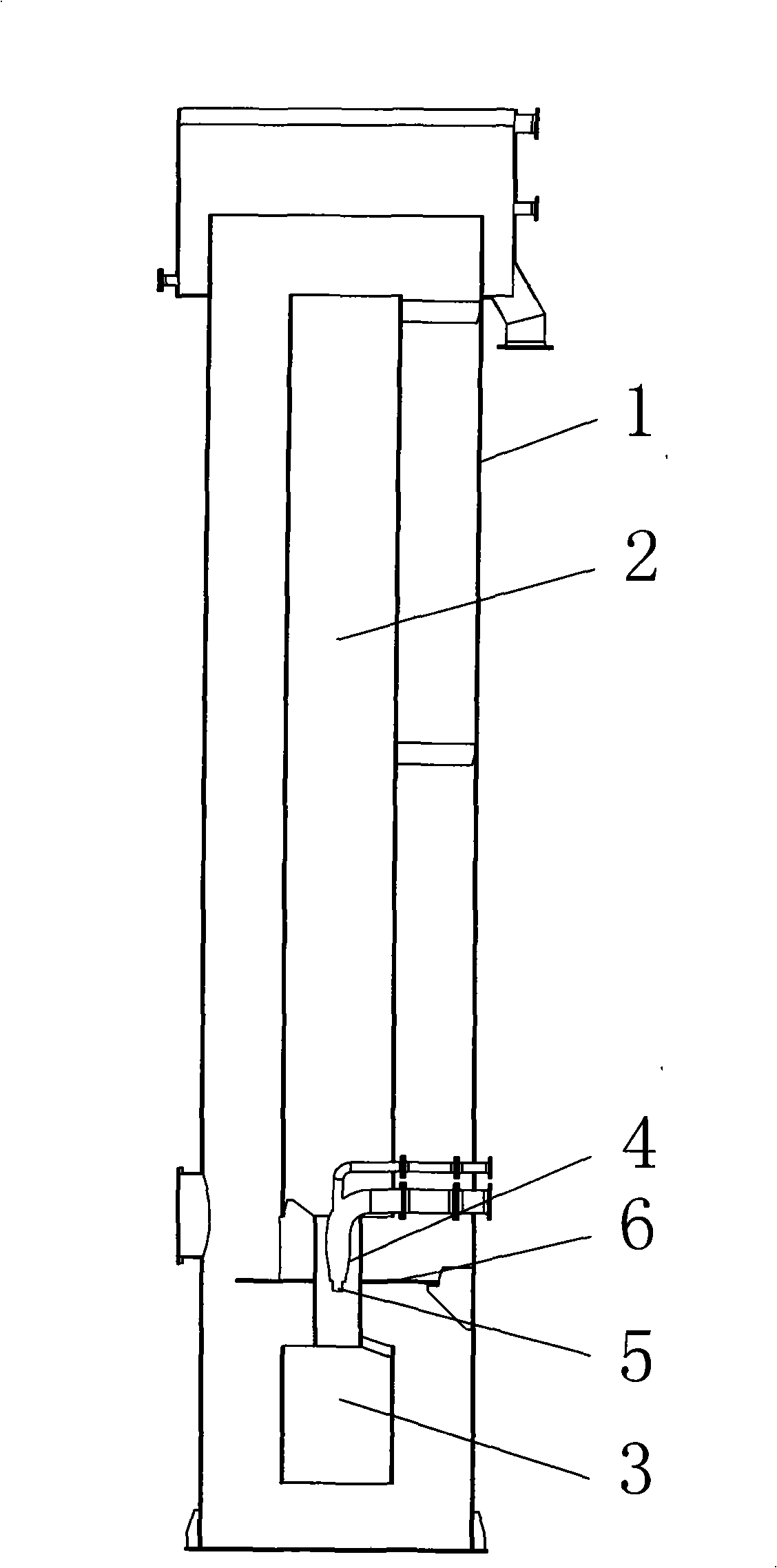

[0030] refer to figure 1 and figure 2, the treatment method of high-concentration organic wastewater of the present invention, the present invention adopts jet ring biochemical reactor and membrane separation combined technology to treat wastewater, wherein the jet ring biochemical reactor includes a shell 1, and the shell is provided with a reaction zone, an exchange zone and mixing tube. An upper circulation pipe 2 is installed in the reaction zone. A lower circulation pipe 3 is installed in the exchange area, and activated sludge generated by bacterial cultivation is pre-installed in the exchange area, and the concentration of the pre-installed activated sludge in the exchange area is 15-18g / L. The mixing pipe 4 is located between the upper circulation pipe 2 and the lower circulation pipe 3, the upper end of the mixing pipe 4 communicates with the upper circulation pipe, and the lower end communicates with the lower circulation pipe. A two-phase nozzle 5 is arranged in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com