Method for preparing yttrium silicate coat by cathode rotation hydrothermal electrophoretic deposition

A cathode rotation and electrophoresis deposition technology, which is applied in the direction of coating, electrolytic coating, electrophoretic plating, etc., to achieve the effect of uniform coating, avoiding repeated operations, and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

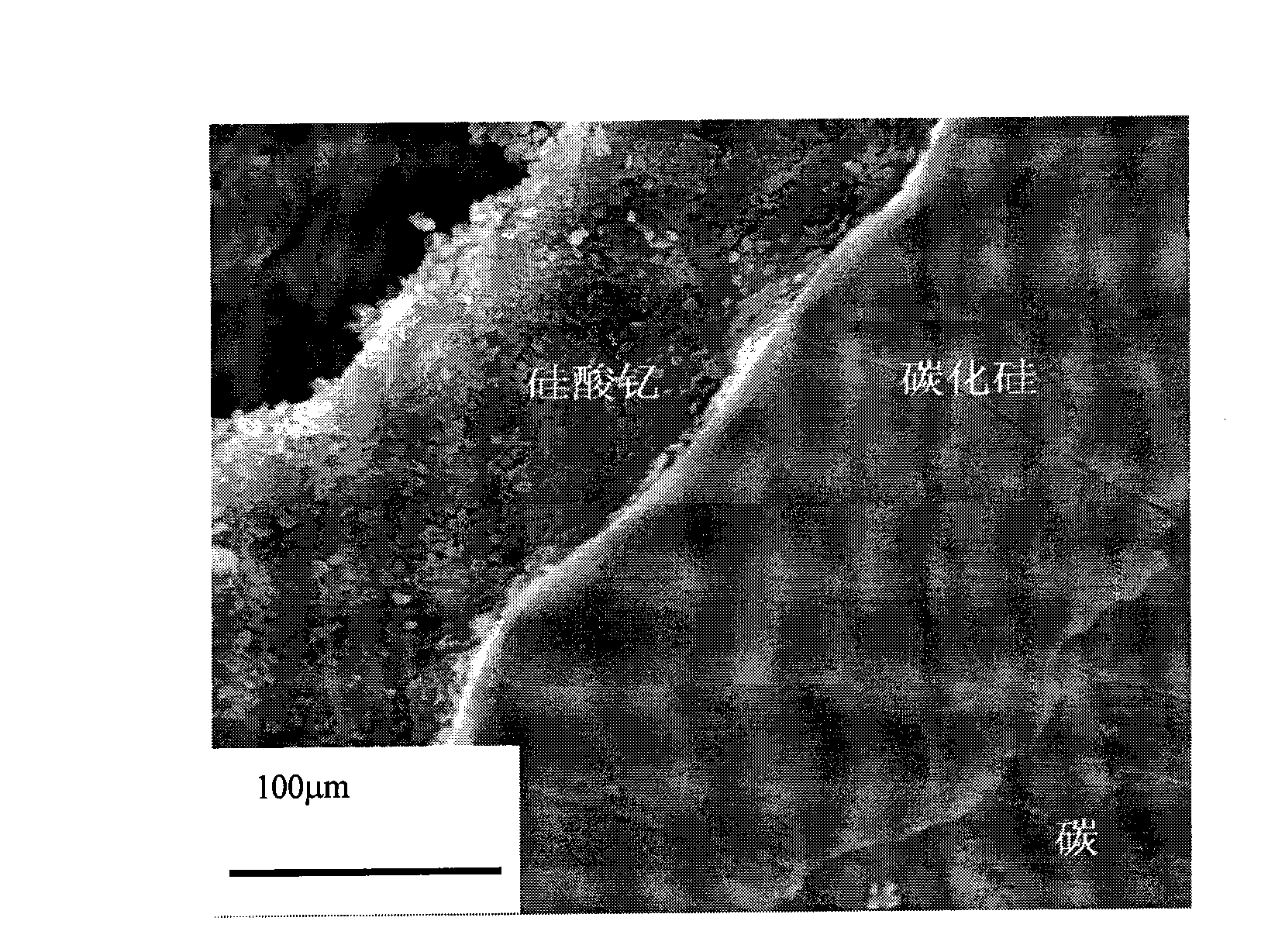

[0014] Embodiment 1: at first, select 5 microns of analytically pure yttrium silicate (Y 2 Si 2 o 7 ) powder, analytically pure isopropanol and iodine as raw materials, according to Y 2 Si 2 o 7 : isopropanol=2.5g: 150ml ratio is prepared into a suspension, after mechanical stirring at 1500r / min for 8h, after introducing iodine in the suspension at a ratio of 0.5g / L and stirring for 12h, place it in an ultrasonic wave at 500W After oscillating under power for 60 minutes, it is ready for use; secondly, the above suspension is added to the hydrothermoelectrophoresis deposition reaction kettle, the graphite electrode is used as the anode, and the carbon / carbon composite material pre-deposited with a SiC coating with a thickness of 100 microns that can be rotated is used as the cathode; Then, after the carbon / carbon composite material pre-deposited with a 50-100 micron thick SiC coating is fixed on the cathode, the hydrothermoelectrophoretic deposition reactor is sealed, and t...

Embodiment 2

[0015] Embodiment 2: at first, select 0.05 micron analysis pure yttrium silicate (Y 2 Si 2 o 7 ) powder, analytically pure isopropanol and iodine as raw materials, according to Y 2 Si 2 o 7: The ratio of isopropanol=5g: 150ml is prepared into a suspension, after mechanical stirring at 2000r / min for 12h, after introducing iodine in the suspension at a ratio of 1.5g / L and stirring for 10h, place it in an ultrasonic wave at a power of 100W After shaking for 10 minutes, it is ready for use; secondly, the above suspension is added to the hydrothermoelectrophoretic deposition reaction kettle, the graphite electrode is used as the anode, and the carbon / carbon composite material with a 50 micron thickness of SiC coating that can be rotated is pre-deposited as the cathode; then After the carbon / carbon composite material pre-deposited with a 50-100 micron thick SiC coating is fixed on the cathode, seal the hydrothermoelectrophoretic deposition reactor, and at the same time heat the ...

Embodiment 3

[0016] Embodiment 3: at first, select 0.5 micron analytically pure yttrium silicate (Y 2 Si 2 o 7 ) powder, analytically pure isopropanol and iodine as raw materials, according to Y 2 Si 2 o 7 : isopropanol=4g: 150ml ratio is prepared into a suspension, after mechanical stirring at 1000r / min for 10h, introduce iodine into the suspension at a ratio of 1g / L and stir for 8h, then place it in an ultrasonic wave at a power of 300W After shaking for 30 minutes, it is ready for use; secondly, the above-mentioned suspension is added to a hydrothermoelectrophoretic deposition reactor, with a graphite electrode as an anode, and a carbon / carbon composite material that can be rotated and pre-deposited with a SiC coating with a thickness of 80 microns as a cathode; then, After the carbon / carbon composite material pre-deposited with a SiC coating with a thickness of 50-100 microns is fixed on the cathode, the hydrothermoelectrophoretic deposition reactor is sealed, and the hydrothermoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com