Method for treating hydrolyzed waste water and recovering resource in disperse blue production process

A production process, resource recovery technology, applied in 2 fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

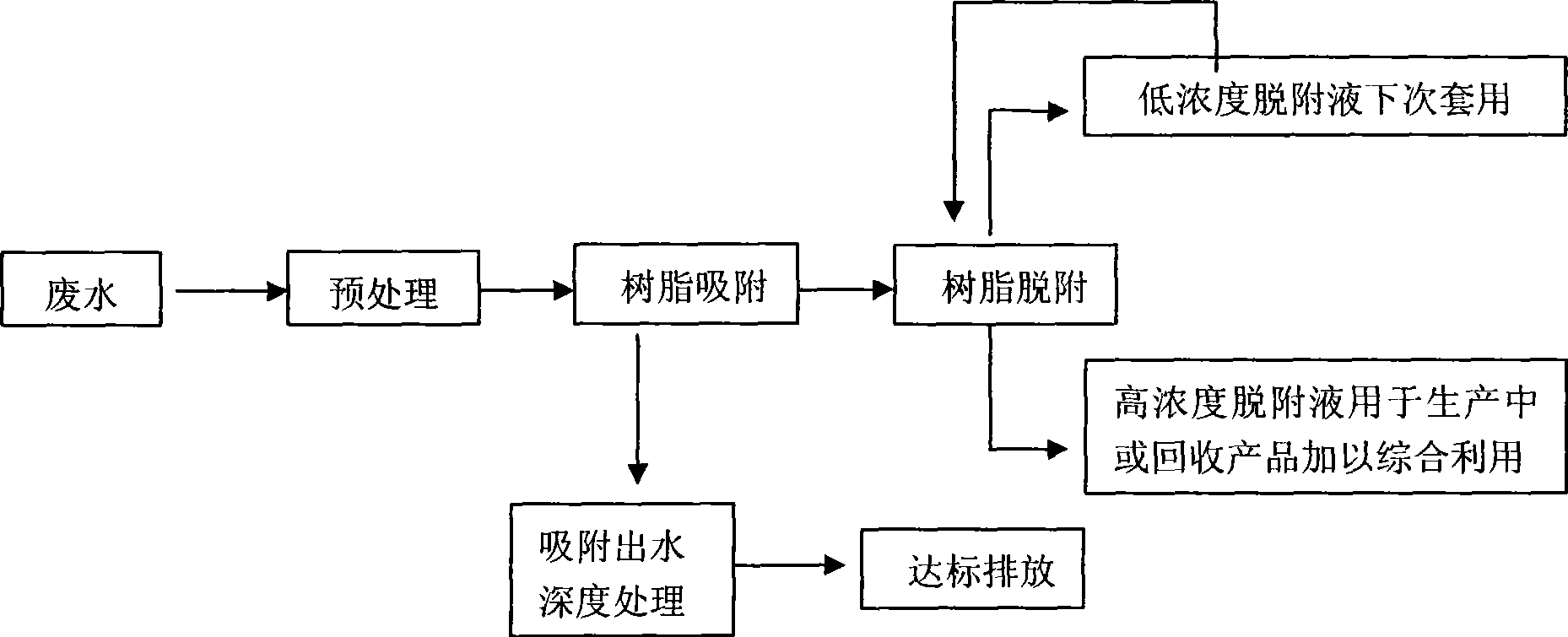

Method used

Image

Examples

example 1

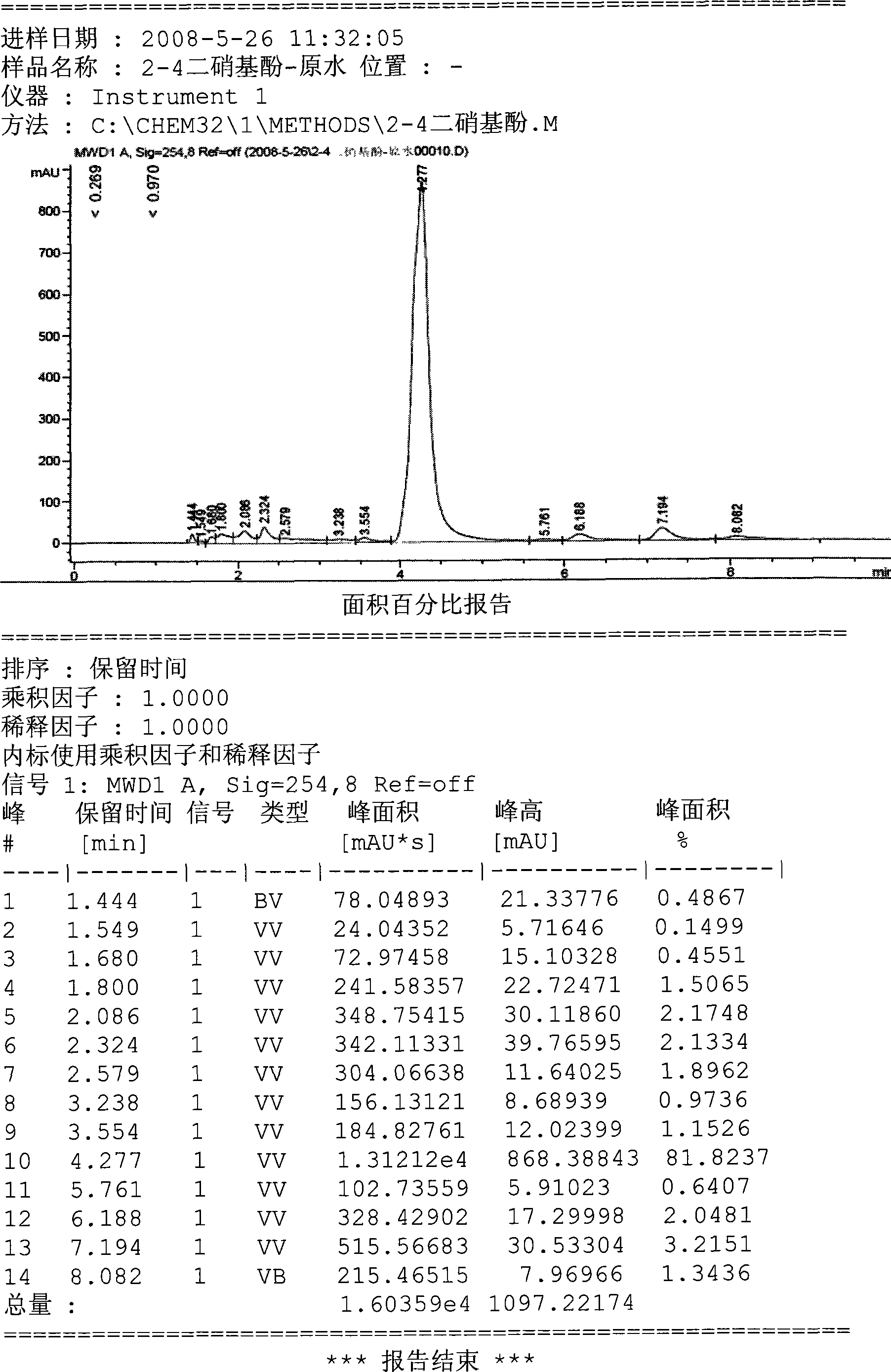

[0029] Example 1: 30 mL (about 22.5 grams) of NDA-150 macroporous adsorption resin was loaded into a jacketed glass adsorption column (Φ20×250 mm). The hydrolysis wastewater (COD) produced in the production process of 600mL disperse blue 2BLN cr 54160mg / L, 2,4-dinitrophenol content is 44395mg / L) with concentrated sulfuric acid to adjust pH=3.0 and then filter, after the filter cake is dried, 26.2 grams of 2,4-dinitrophenol yellow-brown solid can be recovered, The purity reaches 94.2%. Filtrate COD cr The content of 2,4-dinitrophenol is 10202mg / L, and the content of 2,4-dinitrophenol is 2224mg / L. Pass it through the resin bed at a flow rate of 90mL / h at 25±5°C, and the processing capacity is 600mL / batch. After resin treatment, The color of the effluent is light red, the content of 2,4-dinitrophenol is 0.4mg / L, COD cr Dropped to 3361mg / L.

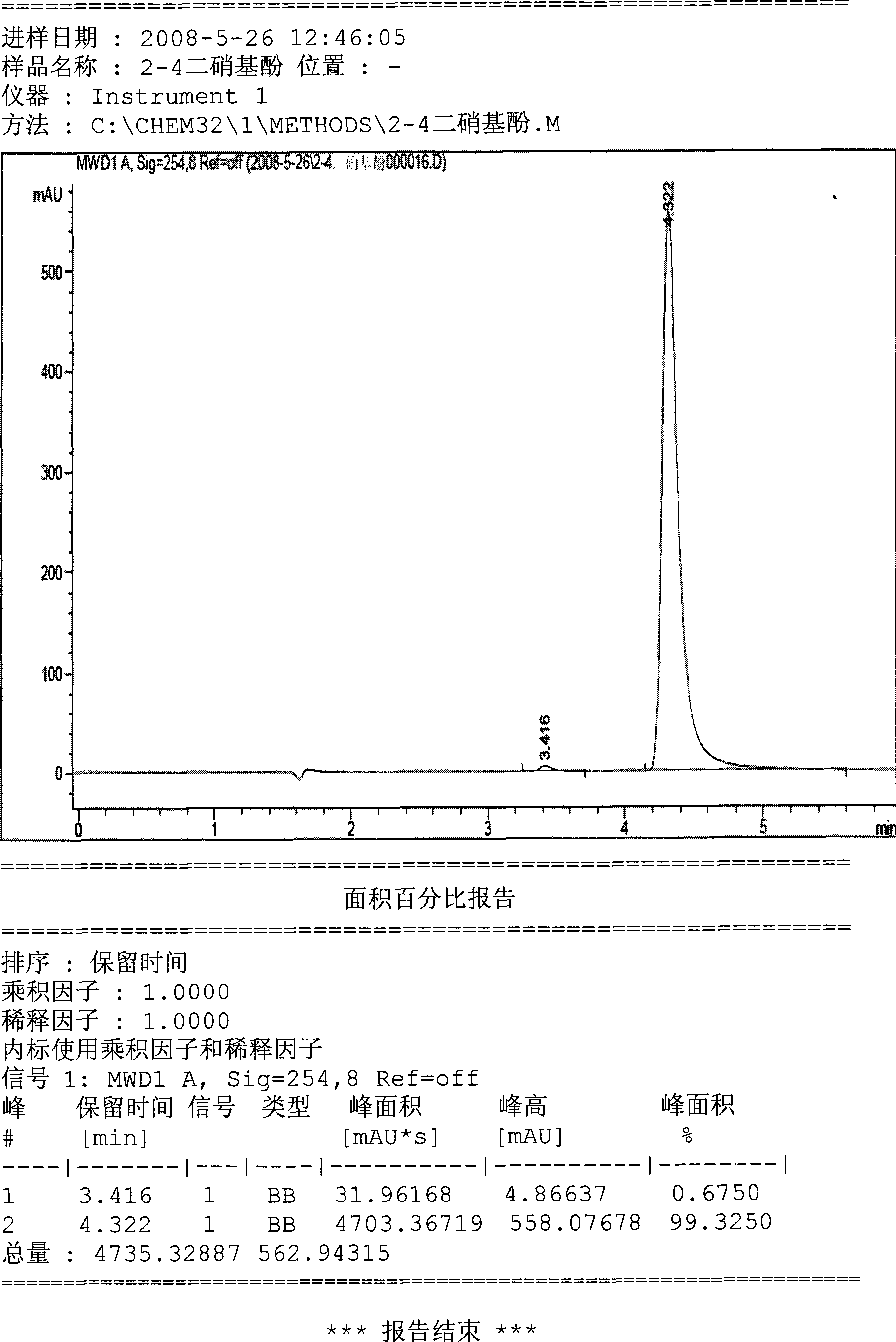

[0030] Use 60mL of 8% (mass ratio) sodium hydroxide, 60mL of 4% sodium hydroxide and 60mL of water successively at a temperature of 80±5...

example 2

[0031] Example 2: 100 mL (about 75 grams) of NDA-150 macroporous adsorption resin was loaded into a jacketed glass adsorption column (F32×360 mm). The hydrolysis wastewater (COD) produced in the production process of 2000mL disperse blue 2BLN cr 54317mg / L, 2,4-dinitrophenol content is 44518mg / L,) adjust pH=2 with concentrated sulfuric acid and filter, after the filter cake is dried, 87.5 grams of 2,4-dinitrophenol yellow-brown solid can be recovered , the purity reaches 93.7%. Filtrate COD cr Reduced to 10992mg / L, 2,4-dinitrophenol content was 2547mg / L, the filtrate passed through the resin bed at a flow rate of 150mL / h at 30±5°C, and the treatment capacity was 2000mL / batch. After resin treatment, The color of the effluent is light red, the content of 2,4-dinitrophenol is 0.43mg / L, COD cr Dropped to 3435mg / L.

[0032]Use 200mL 8% (mass ratio) sodium hydroxide, 200mL 4% sodium hydroxide and 200mL water successively at a temperature of 80±5°C to flow through the resin bed at...

example 3

[0033] Example 3: Choose three 316L stainless steel adsorption towers (F600×3500mm) with the same specifications, and fill each tower with 300 kg (about 400 L) of NDA-150 macroporous adsorption resin. will be 8m 3 Hydrolysis wastewater (COD) produced during the production of disperse blue 2BLN cr 54826mg / L, 2,4-dinitrophenol content is 44520mg / L) adjust pH=2.5 with concentrated sulfuric acid and filter, after the filter cake is dried, reclaim yellow-brown 2,4-dinitrophenol solid 348.2 kilograms, The purity reaches 93.5%. Filtrate COD cr Reduced to 11126mg / L, 2,4-dinitrophenol content was 2270mg / L, the filtrate was at 15±5℃, with 0.4m 3 The flow rate of / h is pumped into the adsorption tower, and the adsorption adopts the method of I and II towers in series and downstream adsorption, and the processing capacity is 8m 3 / batch, after resin treatment, the effluent is nearly colorless, the content of 2,4-dinitrophenol is 0.08mg / L, COD cr Dropped to 1375mg / L.

[0034] will a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com