Double-substrate active layer structure with polysilicon layer and microcrystal silicon layer, method and device thereof

A polycrystalline silicon layer and microcrystalline silicon layer technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of inconsistent luminance of organic light-emitting diode displays, adverse effects of current density, and limited space for improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

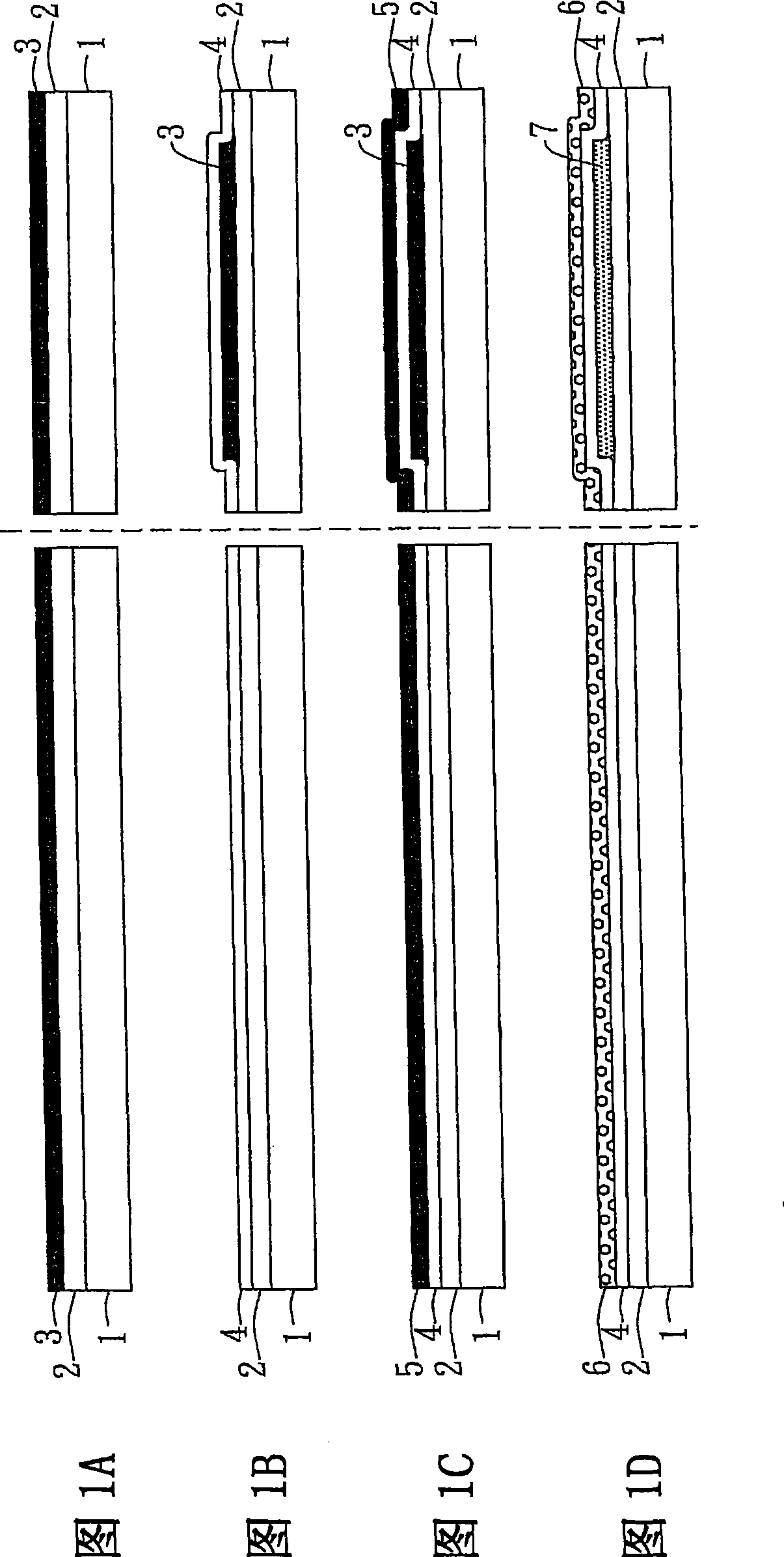

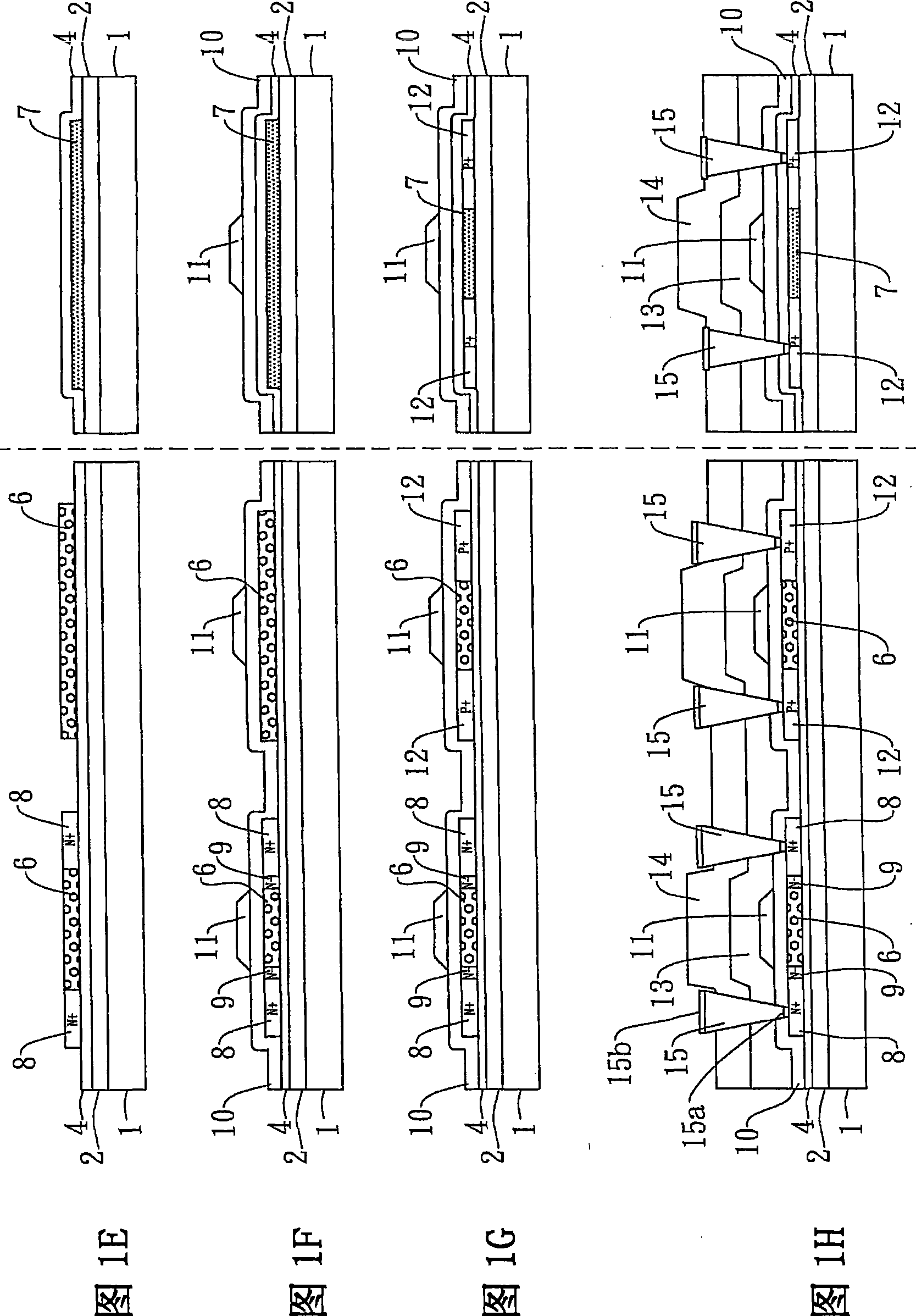

[0029] Refer to Figure 1A to Figure 1D It is a structural cross-sectional schematic diagram corresponding to each step of the manufacturing method of the dual-substrate active layer structure with a polysilicon layer and a microcrystalline silicon layer according to the present invention. With reference to Fig. 1A, the manufacturing method of the dual-substrate active layer structure with polysilicon layer and microcrystalline silicon layer of the present invention first provides a substrate 1, for example glass substrate or other semiconductor substrates, and the right side area of a surface of described substrate 1 defines A display area and its left area define a driving circuit area. A buffer layer 2 is formed above the substrate 1 . Then a first amorphous silicon layer 3 is formed above the buffer layer 2 . Referring to FIG. 1B, the first amorphous silicon layer 3 is pattern etched to form a first active layer in the display area above the substrate 1, the first acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com