Photoelectric substrates

A technology for optoelectronic substrates and light guide plates, which is applied to optical waveguide light guides, coupling of optical waveguides, printed circuit components, etc. The effect of reducing production cost, increasing optical coupling efficiency and reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

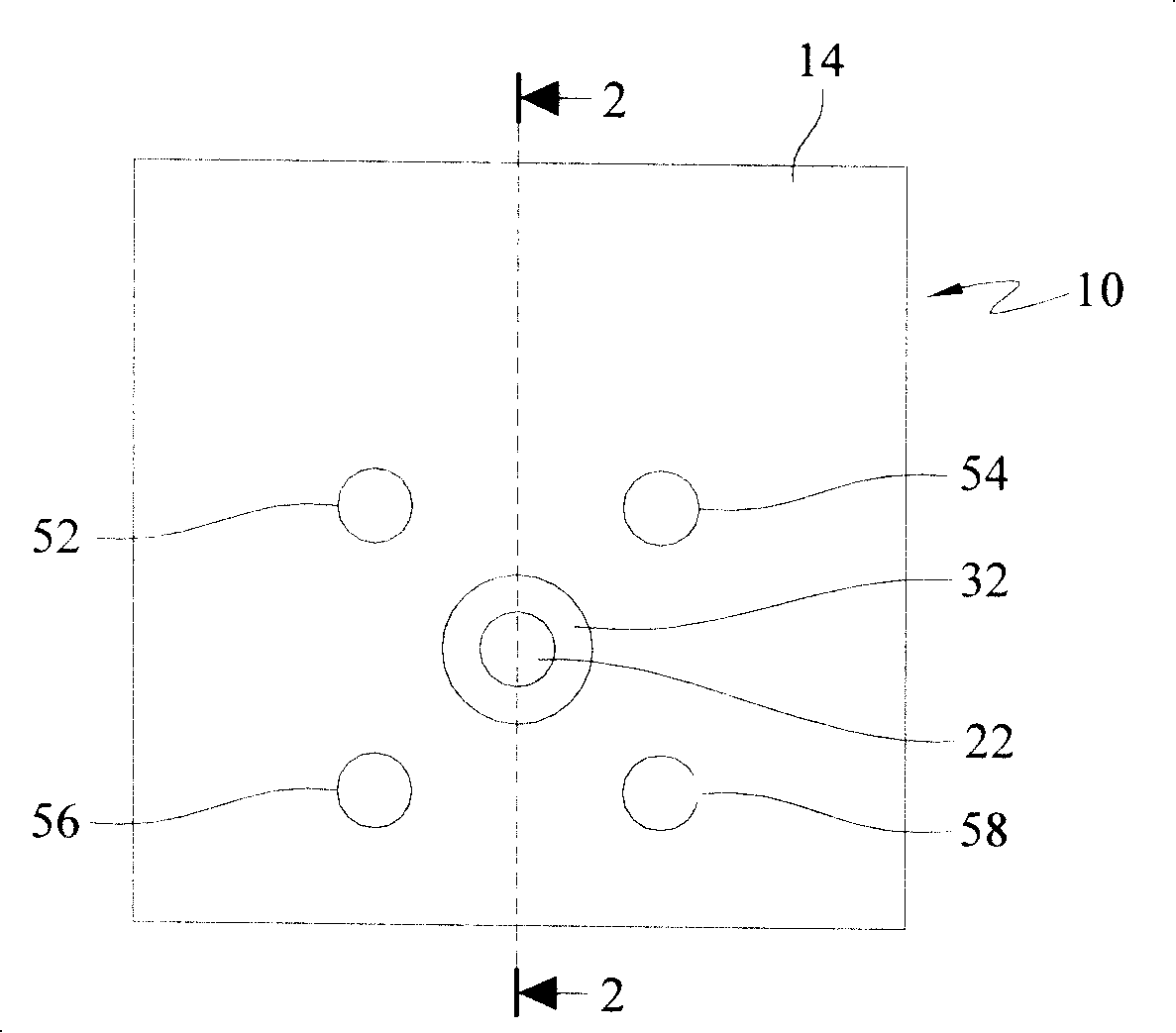

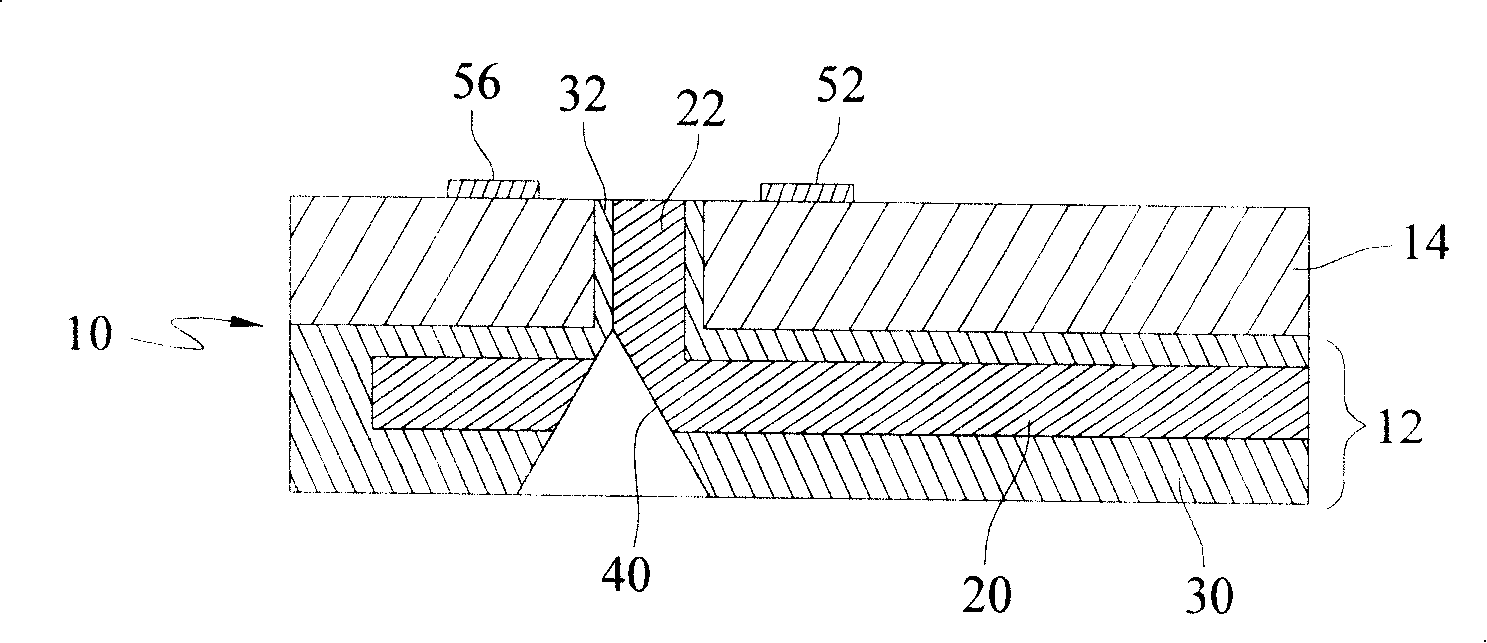

[0033] refer to Figure 4 , Figure 4 It is a schematic diagram of the first embodiment of the light guide plate 100 of the optoelectronic substrate of the present invention. Such as Figure 4 As shown, the light guide plate 100 of the first embodiment of the present invention includes a metal substrate 150, a glass fiber layer 130 formed on the metal substrate 150, a light guide layer 120 formed on the glass fiber layer 130, and a metal support The structure 152 is formed around the light guide layer 120 and on the glass fiber layer 130 .

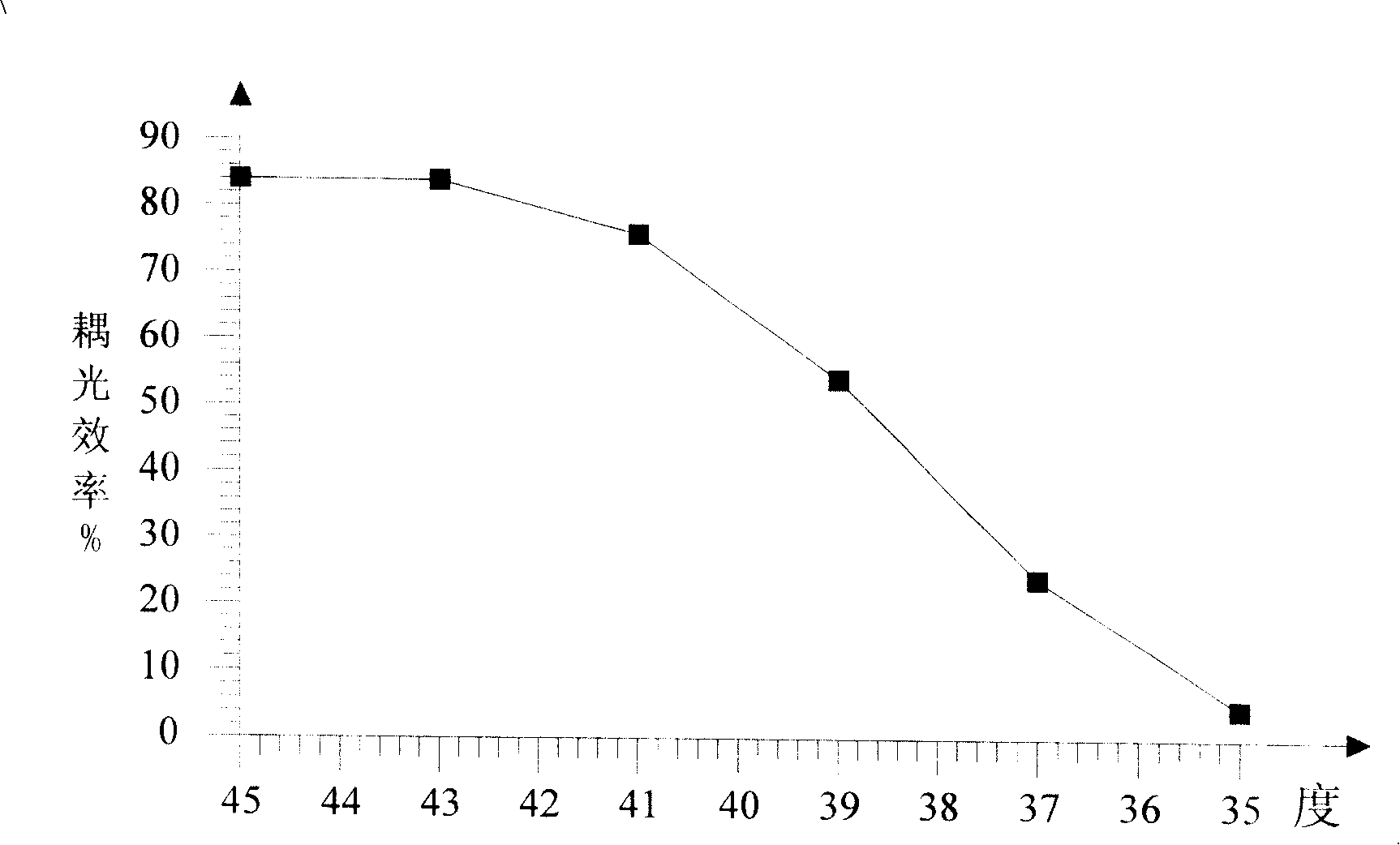

[0034] The light guide layer 120 is composed of a waveguide and a cover layer 112 . In this embodiment, the optical waveguide is a multi-channel optical waveguide, which includes a plurality of cores (Cores) 110 embedded in the cladding layer 112 so that the cladding layer 112 can completely cover the cores 110 . Since the refractive index of the material selected for the cladding layer 112 is lower than that of the fiber core 110 , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com