Heterojunction thermophotovoltaic cell based on Ga-In-As-Sb quarternary semiconductor

A technology of gaxin1-xas1-ysby and gax1in1-x1as1-y1sby1, which is applied in the field of heterojunction thermal photovoltaic cells, can solve the problems of high cost and difficult growth of Al-containing materials, so as to increase the open circuit voltage, improve photoelectric conversion efficiency, and improve Effect of Photogenerated Current Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

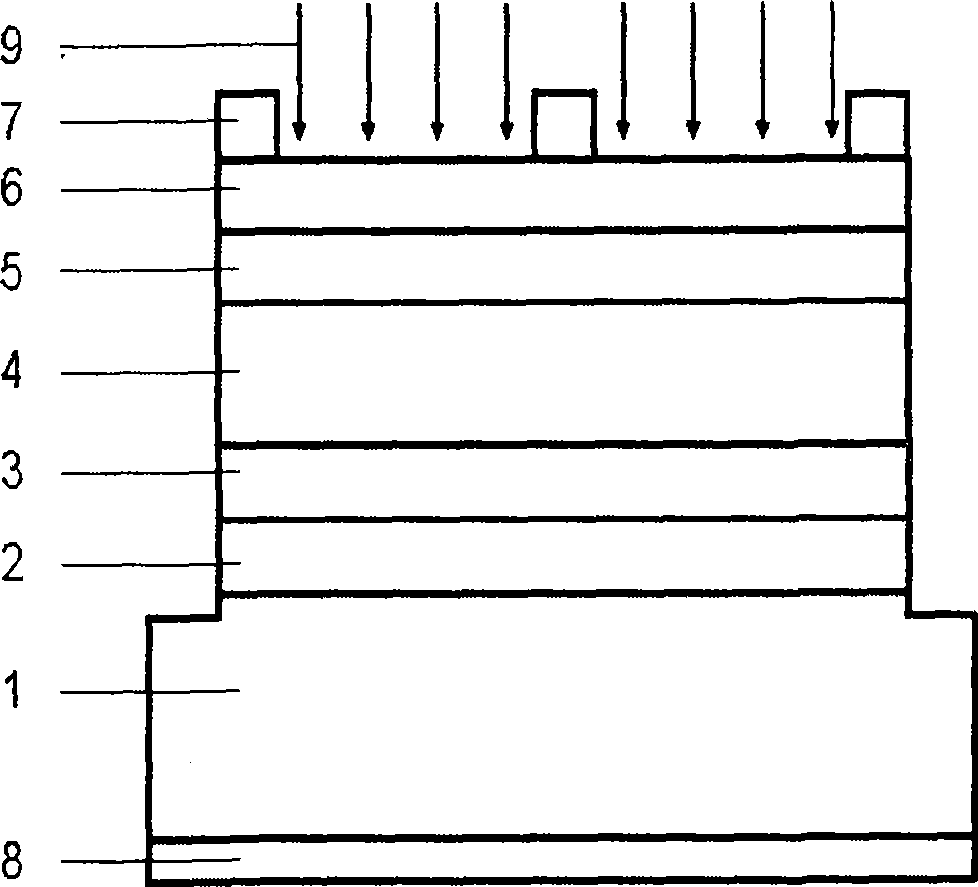

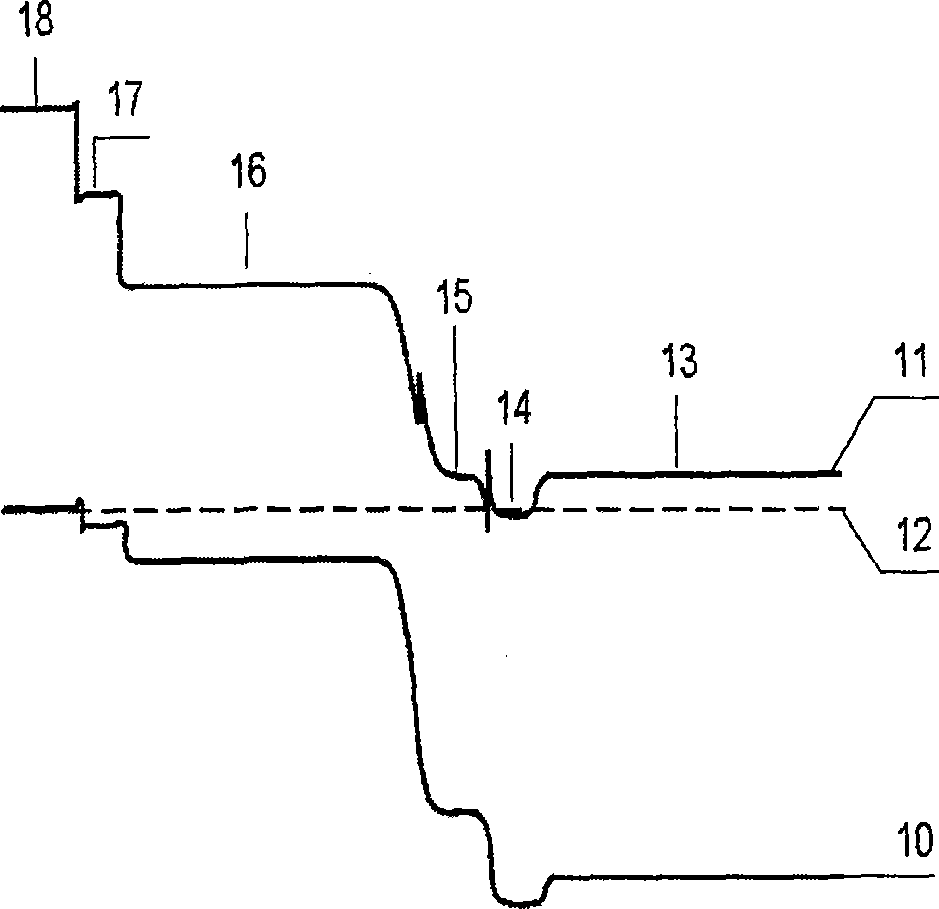

[0027] Te-doped N-type GaSb polished single wafer was used as the substrate, and the net donor concentration was 5×10 17 cm -3 , the crystal orientation is (100), and the prepared structure is N-type GaSb substrate / N + Type GaSb rear confinement layer / N-type Ga 0.95 In 0.05 As 0.04 Sb 0.96 Active layer / P - Type Ga 0.8 In 0.2 As 0.18 Sb 0.82 Active layer / P + Type Ga 0.9 In 0.1 As 0.09 Sb 0.91 Restricted layer / P + Type GaSb window passivation layer of heterojunction Ga x In 1-x As 1-y Sb y Thermal photovoltaic cells.

[0028] The growth of the multilayer material structure is carried out in a low-pressure metal-organic chemical vapor deposition (MOCVD) system. The Ga, In, Sb and As sources used for growth were trimethylgallium (TMGa), trimethylindium (TMIn), trimethylantimony (TMSb) and hydrogen (H 2 ) diluted to 10% (volume percentage) of arsine (AsH 3 ), the metal-organic sources were placed in a high-precision temperature-controlled cold trap, and the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com