Traction power supply direct hanging type high voltage comprehensive compensation device

A technology of traction power supply and comprehensive compensation, applied in harmonic reduction devices, power lines, transportation and packaging, etc., can solve problems such as high-speed and heavy-load operation constraints, limited effects, system performance impact, etc., and achieve good waveform output characteristics and harmony Wave suppression capability, overall efficiency improvement, and manufacturing cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

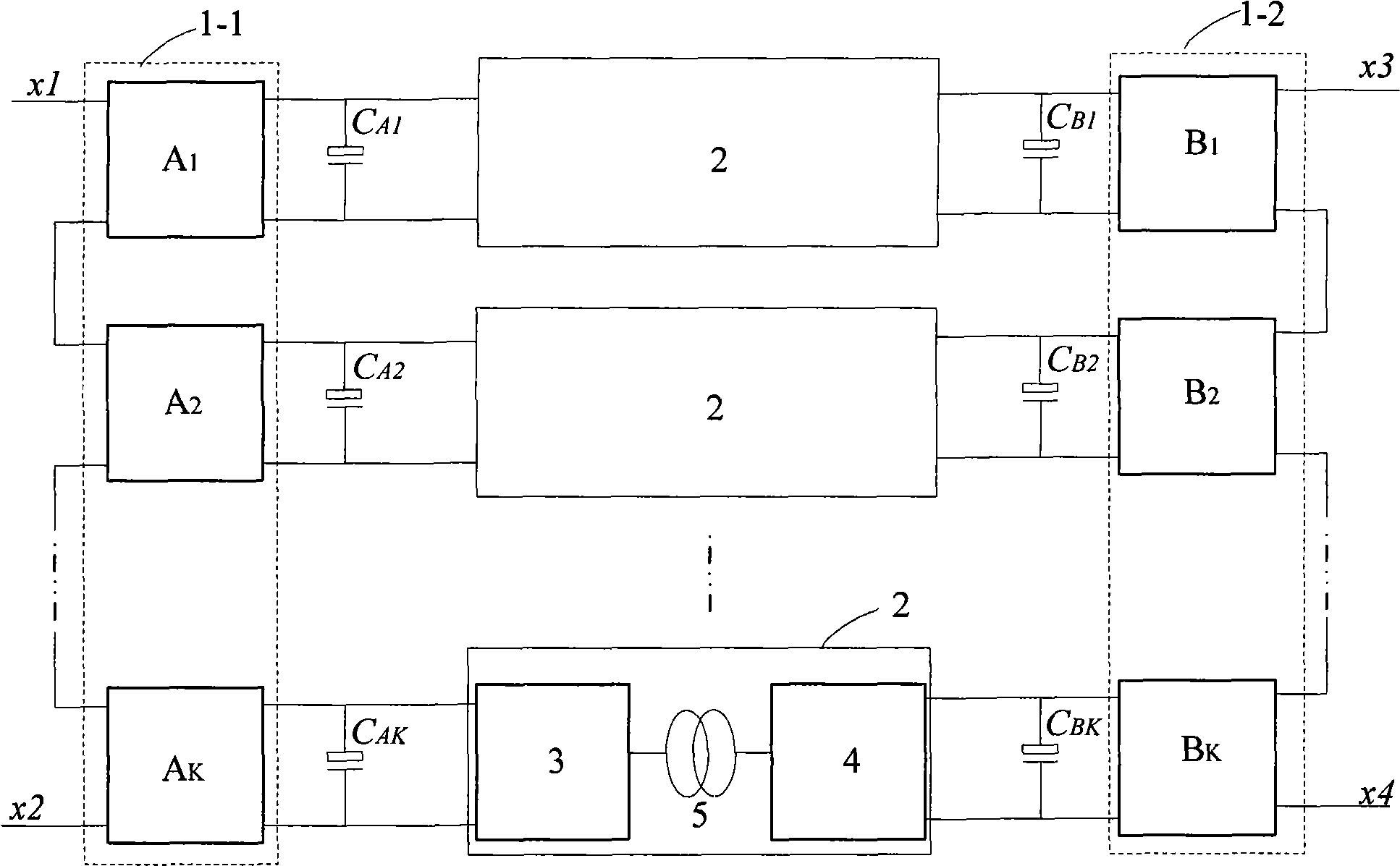

[0016] Embodiments of the present invention will be further described in conjunction with the accompanying drawings:

[0017] figure 1 It is a schematic diagram of the direct-mounted high-voltage comprehensive compensation device for traction power supply of the present invention. It includes 2 K-level cascaded bridge arms, 2K energy storage capacitors, and K isolated bidirectional DC converters 2; The frequency isolation transformer 5 is connected to form; the DC outlet terminals of the K rectification-side voltage converters 3 pass through the energy storage capacitor C in sequence A1 、C A2 ...C AK and the power unit A of the left K-level cascaded bridge arm 1-1 1 、A 2 ...A K Parallel connection, at the same time the power unit A of the left K-level cascaded bridge arm 1-1 1 、A 2 ...A K The input and output terminals of the AC side are connected in series sequentially; the DC outlet terminals of the K inverter side voltage converters 4 are sequentially passed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com