Preparation method of combined porous biological ceramics bracket

A bioceramic and combined technology, applied in medical science, prosthesis, etc., can solve the problems of weak bearing capacity of porous ceramic stents, customized production of difficult individual differences in patients, etc., and achieve the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

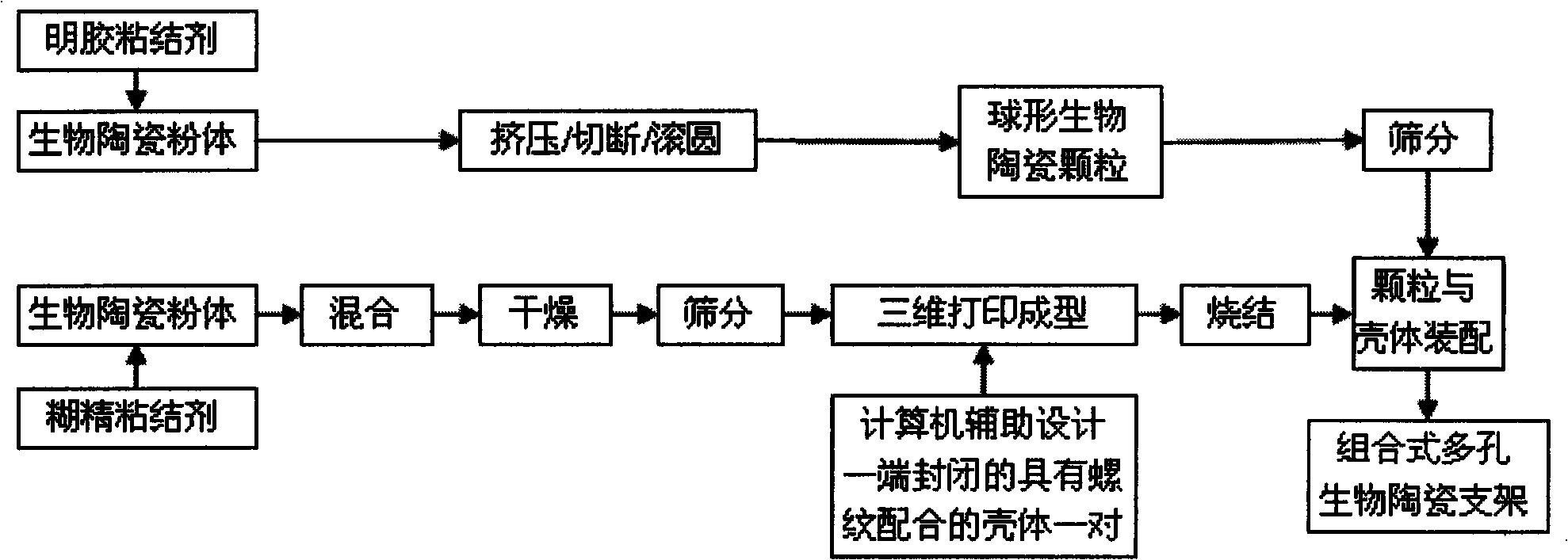

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of a combined porous bioceramic scaffold with an internal pore diameter greater than 100 μm.

[0037]This porous bioceramic scaffold can ensure that osteoclasts with a diameter of 100 μm pass through each pore. Referring to Table 1, select the 24-mesh and 26-mesh sieves to screen out the internal pore structure of the spherical particle structure scaffold with a diameter between 710 and 800 μm, and the pore size is between 110 and 586 μm. The specific process is as follows:

[0038] (1.1) Take a gelatin aqueous solution with a mass concentration of 5% as a binder, mix the gelatin aqueous solution with a weight percentage of 30 wt% and the tricalcium phosphate bioceramic powder with a weight percentage of 70 wt%, and use Shenzhen Xinyite Pharmaceutical Equipment The Mini-250 Extrusion Spheronizer produced by the Co., Ltd. performs orifice plate extrusion, cutting and spheronization processes on ceramic powder to produce tricalcium phosphate spheri...

Embodiment 2

[0044] Example 2: Preparation of a combined porous bioceramic scaffold with an internal pore diameter of less than 400 μm.

[0045] This porous bioceramic scaffold has good osseointegration performance. Studies have shown that when the pore size is greater than 400 μm, the bonding force of bone decreases. Referring to Table 1, select 35-mesh and 40-mesh sieves to screen out the internal pore structure of the spherical particle structure scaffold with a diameter between 450 and 500 μm, and the pore size is between 70 and 366 μm. The specific process is as follows:

[0046] (2.1) Take a gelatin aqueous solution with a mass concentration of 3% as a binder, mix the gelatin aqueous solution with a weight percentage of 20 wt% and the calcium-deficient hydroxyapatite bioceramic powder with a weight percentage of 80 wt%, and use Shenzhen Sine The Mini-250 extrusion spheronizer produced by Te Pharmaceutical Equipment Co., Ltd. implements orifice plate extrusion, cutting and spheroniz...

Embodiment 3

[0052] Example 3: Preparation of a combined porous bioceramic scaffold with an internal pore diameter of less than 800 μm.

[0053] This porous bioceramic scaffold has better blood circulation ability, which is beneficial to realize bone repair in parts far away from the heart where blood circulation is weak. Referring to Table 1, select 18-mesh and 20-mesh sieves to screen out the inside of the particle structure scaffold with a diameter between 900 and 1000 μm, and a pore size between 139 and 732 μm. The specific process is as follows:

[0054] (3.1) Take a gelatin aqueous solution with a mass concentration of 4% as a binder, mix the gelatin aqueous solution with a weight percentage of 50 wt% and the alumina bioceramic powder with a weight percentage of 50 wt%, and use Shenzhen Xinyite Pharmaceutical Equipment Co., Ltd. The Mini-250 extrusion spheronizer produced by the company performs orifice plate extrusion, cutting and spheronization processes on the ceramic powder to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com