Aromatic polycarbonate resin composition with light diffusibility

A technology of polycarbonate resin and resin composition, which can be used in lighting and heating equipment, diffusion elements, lighting devices, etc., and can solve problems such as insufficient thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

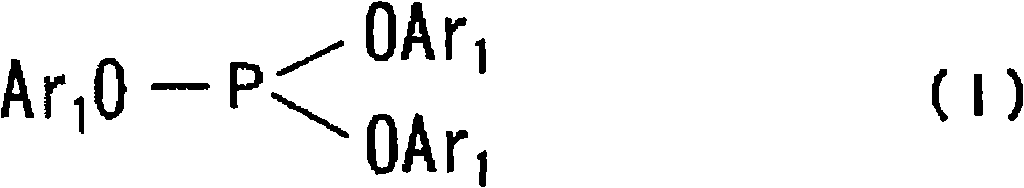

Method used

Image

Examples

Embodiment approach

[0155] Each characteristic value was measured by the following method.

[0156] (1) 5% weight reduction temperature

[0157] Based on JIS K7120, the measurement was performed using a TGA measuring device in a nitrogen atmosphere in a temperature range from 23° C. to 900° C. and under measurement conditions of a temperature increase rate of 20° C. / min. In the weight reduction process, when a weight reduction of 5% was confirmed, the temperature at that time was defined as the 5% weight reduction temperature.

[0158] (2) Total light transmittance

[0159] At a cylinder temperature of 280°C and the conditions described later, a test piece with a side length of 50 mm and a thickness of 2 mm was prepared, and the haze meter HR-100 manufactured by Murakami Color Technology Research Institute was used to measure the thickness in the thickness direction based on ASTMD1003. Transmittance.

[0160] (3) Dispersion

[0161] Under the cylinder temperature of 280° C. and the conditions...

manufacture example

[0180] (Preparation of PMMA-1)

[0181] Into a polymerizer equipped with a stirrer and a thermometer, 500 parts by weight of deionized water in which 0.1 part by weight of sodium lauryl sulfate was dissolved was charged, and 50 parts by weight of tertiary calcium phosphate was dispersed therein. Into it again, put in the polymerizable monomer component that has prepared in advance 90 weight parts of methyl methacrylate, trimethylolpropane triacrylate 10 weight parts and dissolve 0.5 weight part of benzoyl peroxide, even A mixture of 0.5 parts by weight of nitrogen bisisobutyronitrile and 0.5 parts by weight of Adecastab PEP-24G (manufactured by Asahi Denka Co., Ltd.) as a phosphite antioxidant was stirred with a T.K homomixer at 10,000 rpm for 10 minutes to prepare a liquid After the droplet diameter became about 3 μm, 3.0 parts by weight of Adecastab PEP-24G (manufactured by Asahi Denka Co., Ltd.) was added as an antioxidant. Next, the polymerizer was heated to 65° C., and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com