Method for stabilizing content of trivalent chromium and minimum hexavalent chrome in leather

A technology of trivalent chromium minimization, applied in leather impregnation, small raw hide/big raw hide/leather skin/fur chemical treatment, leather surface treatment, etc., to achieve the effect of low treatment cost, low price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

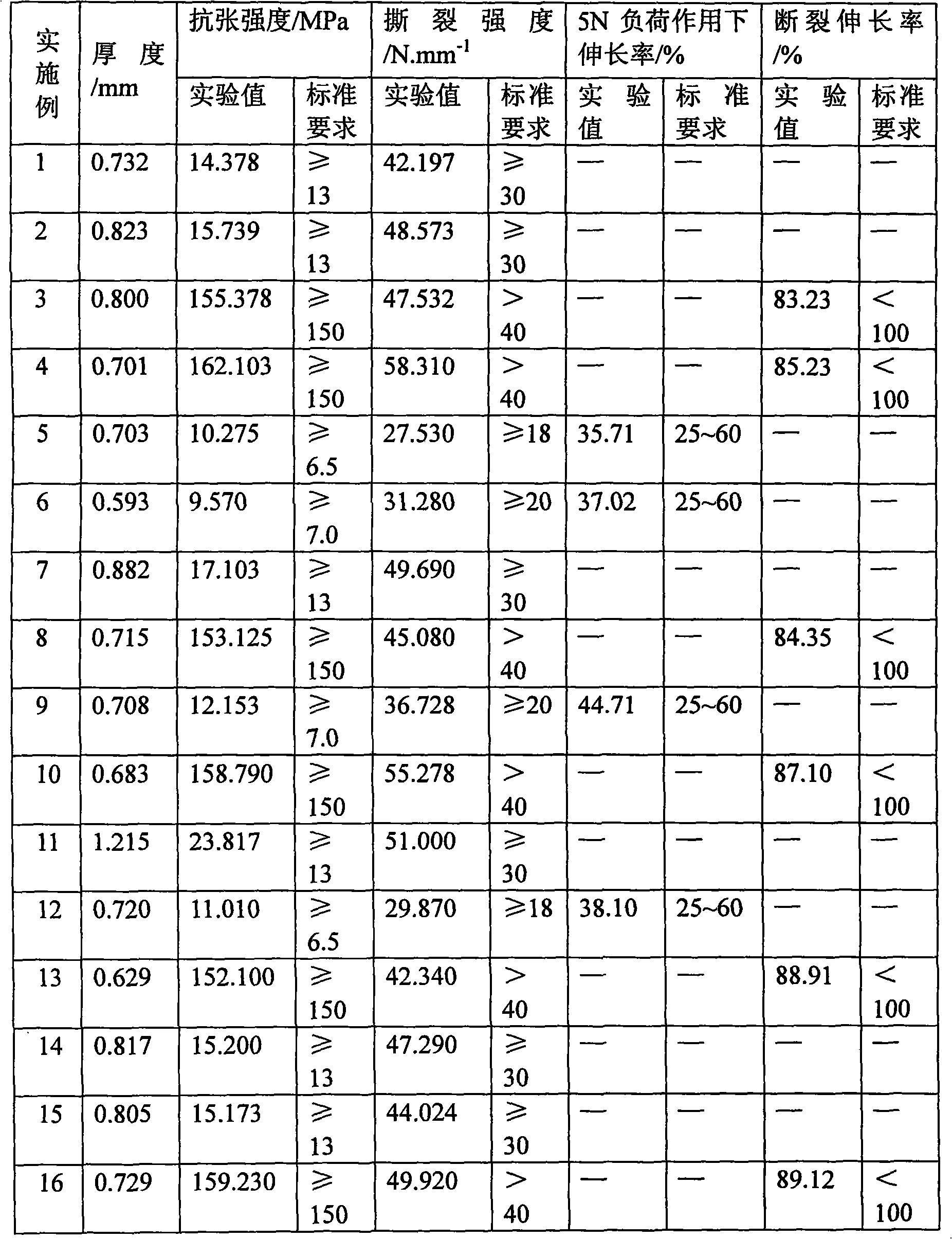

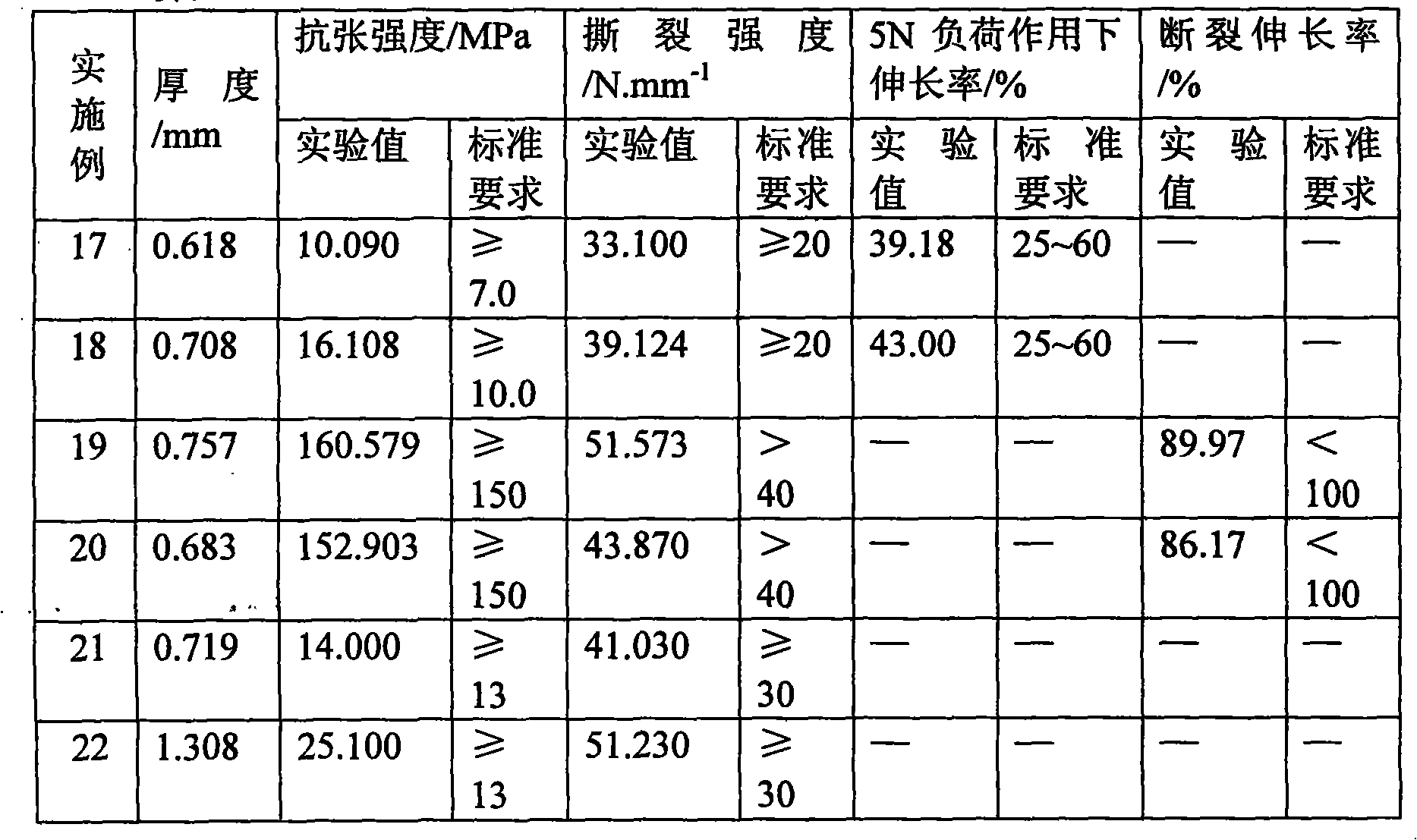

Examples

Embodiment 1

[0025] First weigh sodium sulfite and sodium salicylate respectively, and prepare them into aqueous solutions with a concentration of 3.0% and 0.5% respectively; 45mg / kg light gray sheepskin shoe upper leather, sprayed 3 times; then sprayed the prepared sodium salicylate aqueous solution, also sprayed 3 times; finally sprayed the sheepskin shoe upper leather after the treatment according to the meat surface of the meat surface. The method is to stack it in a normal temperature sheltered environment with a relative humidity of 45-55%. After stacking for 14 days, it can be dried and supplemented with finishing. Hexavalent chromium cannot be detected in the finished leather after treatment.

Embodiment 2

[0027] First weigh soluble starch and potassium cyclohexyl hexaphosphate respectively, and prepare them into aqueous solutions with a concentration of 2.0% and 1.5% respectively; The meat surface of the light yellow goatskin shoe upper leather with a chromium content of about 9mg / kg is sprayed twice; then the prepared aqueous solution of potassium hexaphosphate hexaphosphate is sprayed for 3 times; finally the treated goatskin shoe upper leather is sprayed Stack them in a normal temperature and wind sheltered environment with a relative humidity of 60-70% according to the meat face-to-meat mode, and after stacking for 5 days, dry and supplementary finishing process to it. Hexavalent chromium cannot be detected in the finished leather after treatment.

Embodiment 3

[0029] First weigh sucrose and ammonium citrate respectively, and prepare them into aqueous solutions with a concentration of 2.5% and 1.0% respectively; The meat side of the inner leather of beige pigskin shoes / kg is sprayed 2 times; then the prepared ammonium citrate aqueous solution is sprayed and sprayed 3 times; finally, the pigskin shoe inner leather after the spraying process is piled up in a way that the meat faces the meat side. In a normal temperature sheltered environment with a relative humidity of 65-75%, it can be dried and supplemented with finishing after stacking for 7 days. Hexavalent chromium cannot be detected in the finished leather after treatment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap