Method for increasing temperature of aluminum electrolysis pre-baked green anode dry material

A raw anode and aluminum electrolysis technology is applied in the field of material temperature increase in the production process of prebaked anodes for aluminum electrolysis, which can solve the problems of poor wettability of material particles and affect the quality of material kneading, etc. Increase the effect of the heating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

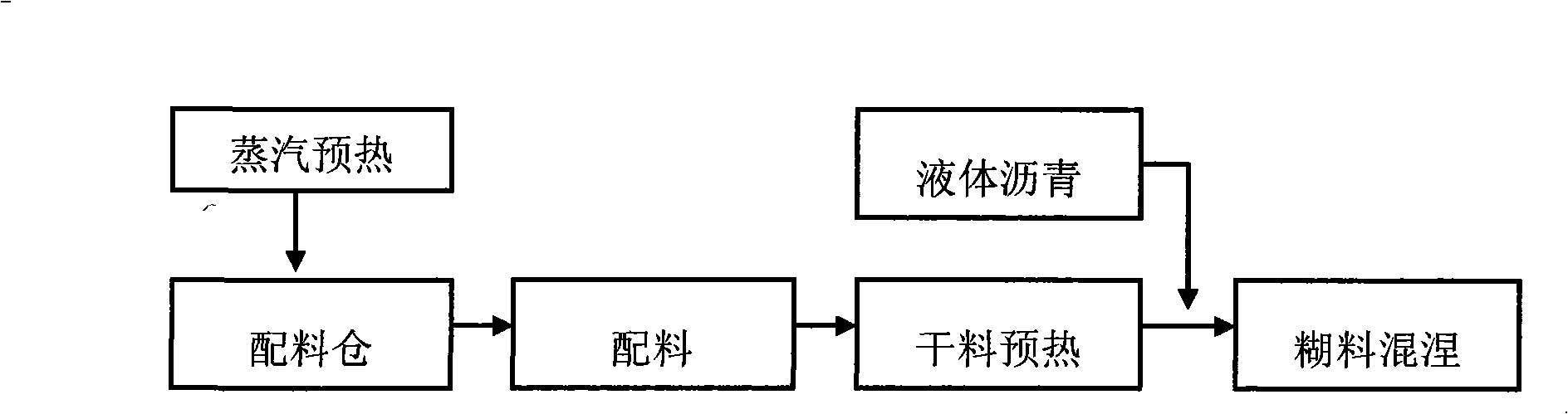

[0019] Such as figure 1 As shown, the paste making process of the prebaked anode for aluminum electrolysis of the present invention is: steam preheating → batching bin → batching → secondary preheating of dry materials + liquid pitch → paste mixing.

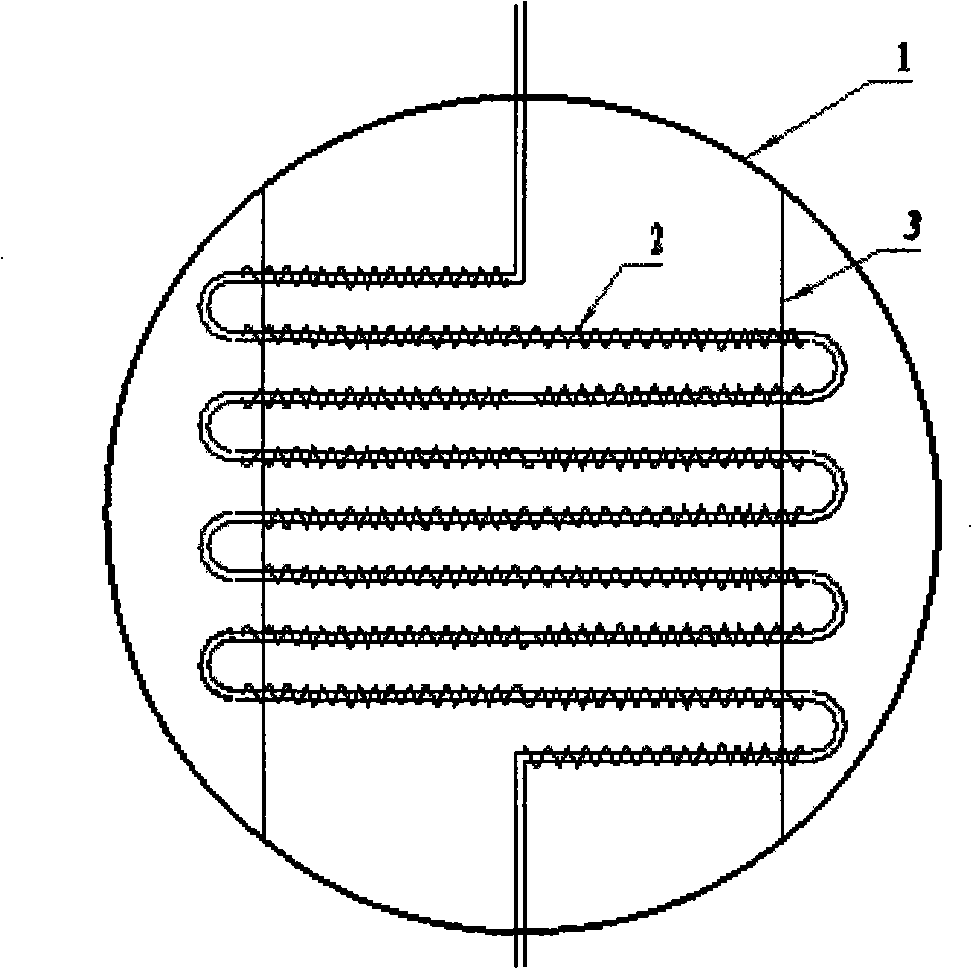

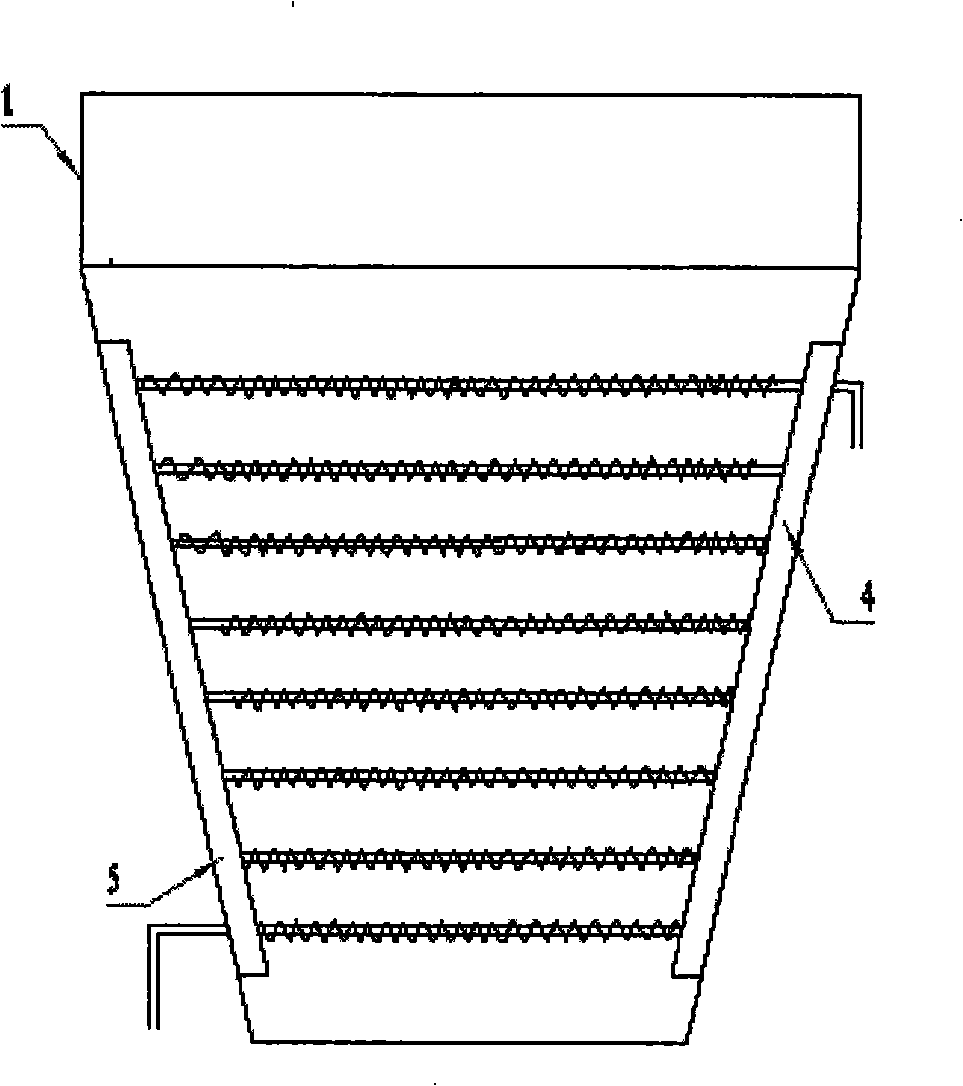

[0020] The dry material preheating is to make a steam heating device in the heating device, which is composed of several layers of U-shaped heating coils (in order to ensure the heat exchange efficiency, the size and layer spacing of the U-shaped coils should be reasonably controlled). The device is fixed inside the batching bin with a bracket of sufficient strength, and the coil is fixed on the bracket by pressing. The steam enters from the inlet of the heat exchanger and passes through the heat exchange device, so that the pipes gain heat under the action of forced convection and conduction of the steam. During the process of the material moving down slowly in the silo, part of the material contacts with the high-temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com