Polylactic acid non-weaving cloth with high strength and low thermal contraction and manufacture method thereof

A technology of non-woven fabrics, manufacturing methods, applied in the direction of non-woven fabrics, textiles and papermaking, single-component polyester rayon, etc., to achieve the effect of wide application and low heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

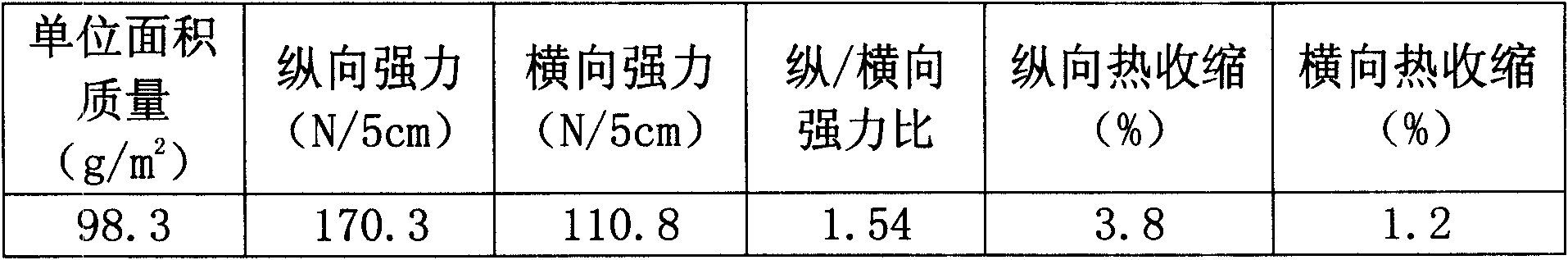

[0020] Use polylactic acid slices with L polylactic acid content ≥ 95%, L lactic acid monomer content ≤ 5%, melting point 160°C, and melt index 50g / 10min as raw materials; pre-crystallize polylactic acid slices at 100°C for 20 minutes; The lactic acid slices are fully dried, the drying temperature is 95°C, and the drying time is 6 hours. The water content of the polylactic acid slices after drying is ≤45ppm; the dried polylactic acid slices are melted and extruded in a screw extruder, and the melt temperature is 178 ℃; the melt is transported to the spinneret through the metering pump and extruded to form filaments, the metering pump is 25r / min; the filaments are cooled evenly by double-side air cooling, and the cooling temperature is 15°C; the filaments are passed through the drafter at high speed The filaments are drawn by the airflow and evenly spread on the moving mesh curtain to form a fiber net. into 100g / m 2 Fibrous web; the obtained fibrous web is sent into a two-roll...

Embodiment 2

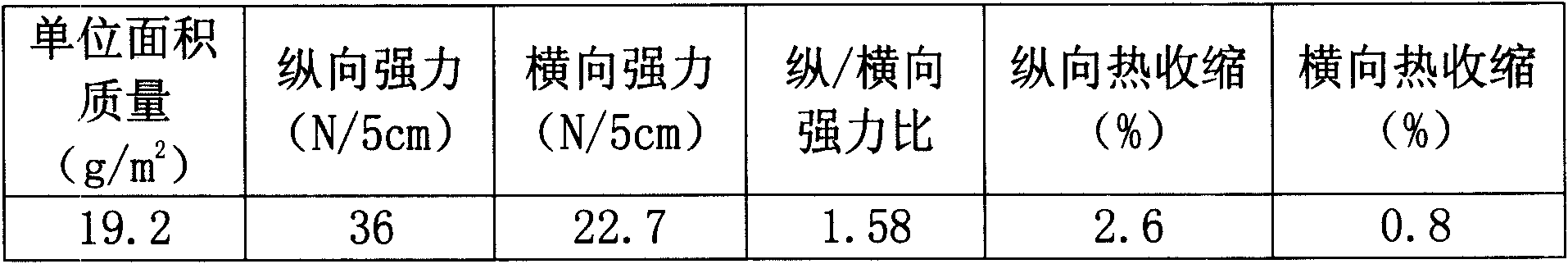

[0022] Use polylactic acid slices with L polylactic acid content ≥ 95%, L lactic acid monomer content ≤ 5%, melting point 160°C, and melt index 30g / 10min as raw materials; pre-crystallize polylactic acid slices at 100°C for 20 minutes; The lactic acid slices are fully dried, the drying temperature is 95°C, and the drying time is 6 hours. The water content of the polylactic acid slices after drying is ≤45ppm; the dried polylactic acid slices are melted and extruded in a screw extruder, and the melt temperature is 178 ℃; the melt is transported to the spinneret through the metering pump and extruded to form filaments, the metering pump is 25r / min; the filaments are cooled evenly by double-side air cooling, and the cooling temperature is 18°C; the filaments are passed through the drafter at high speed The filaments are drawn by the air flow and evenly spread on the moving mesh curtain to form a fiber net. The wire speed is 4200-4500m / min, the pressure of the compressed air is 0.4M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com