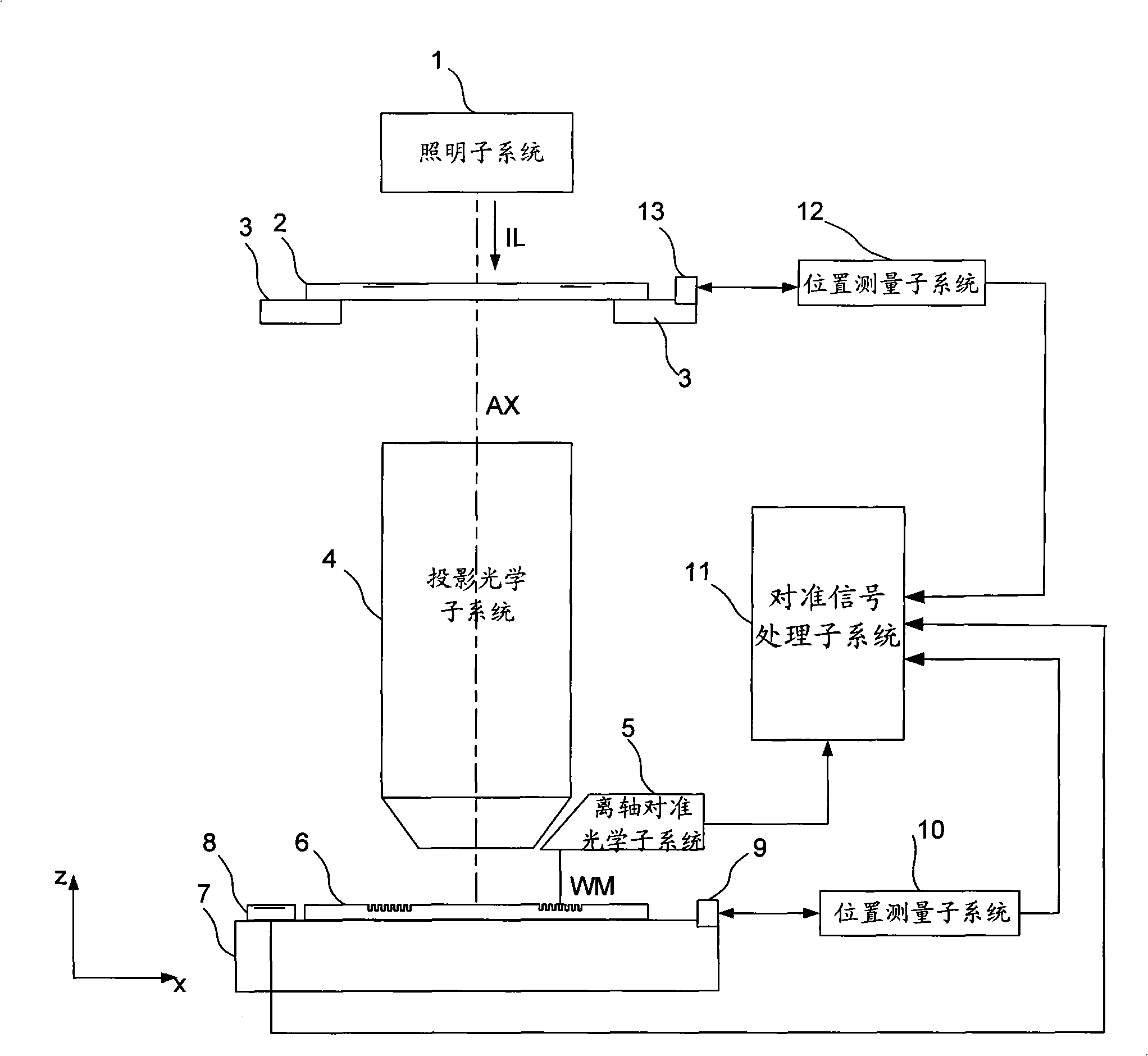

Memory device, method and aligning control system for photoetching aligning data detection

A technology for data inspection and lithography alignment, which is applied in the general control system, control/adjustment system, exposure device for photo-plate making process, etc., can solve the problems of wrong alignment results, uncertain read and write timing, and inconsistent timing, etc., to achieve Avoid the effect of reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

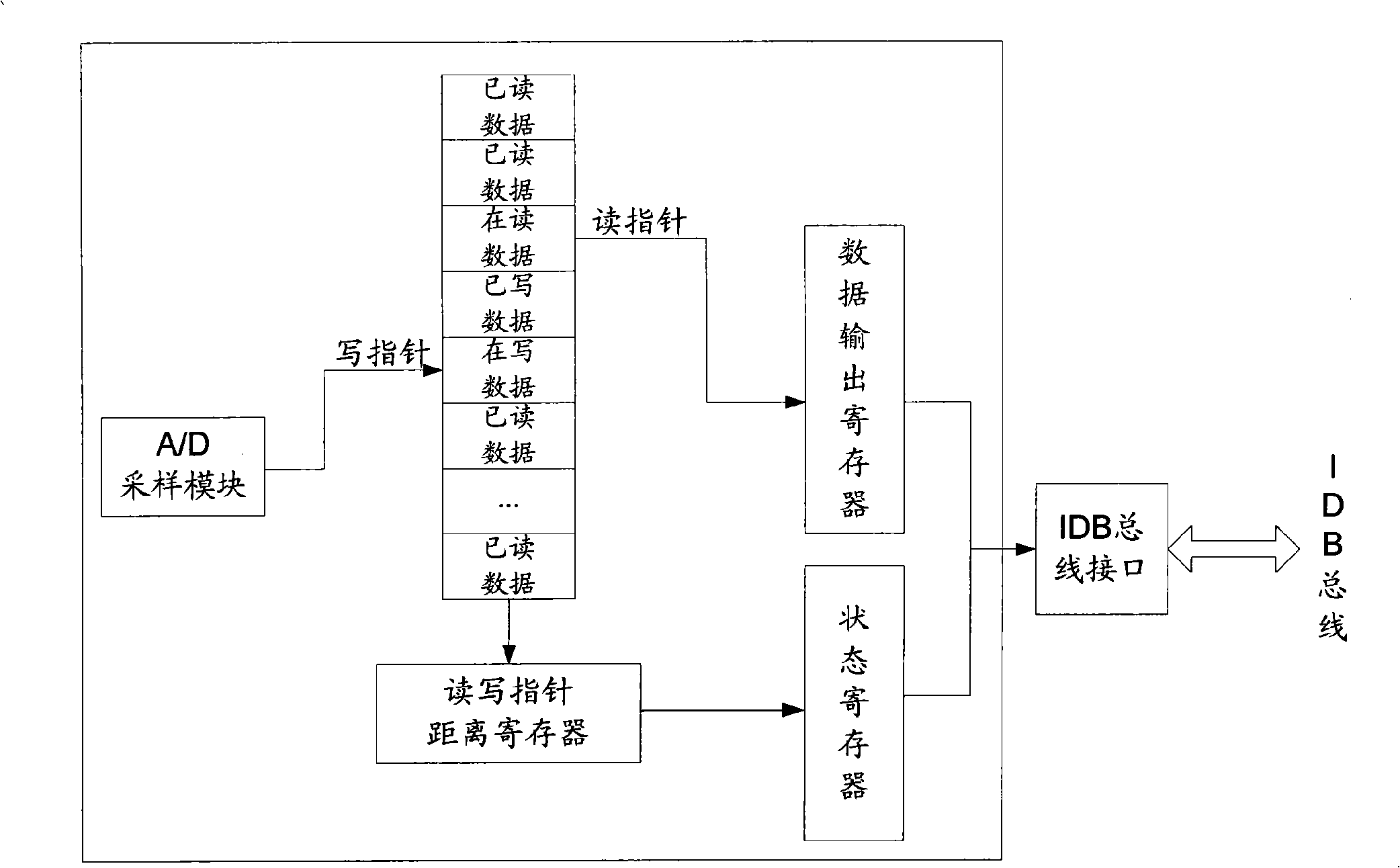

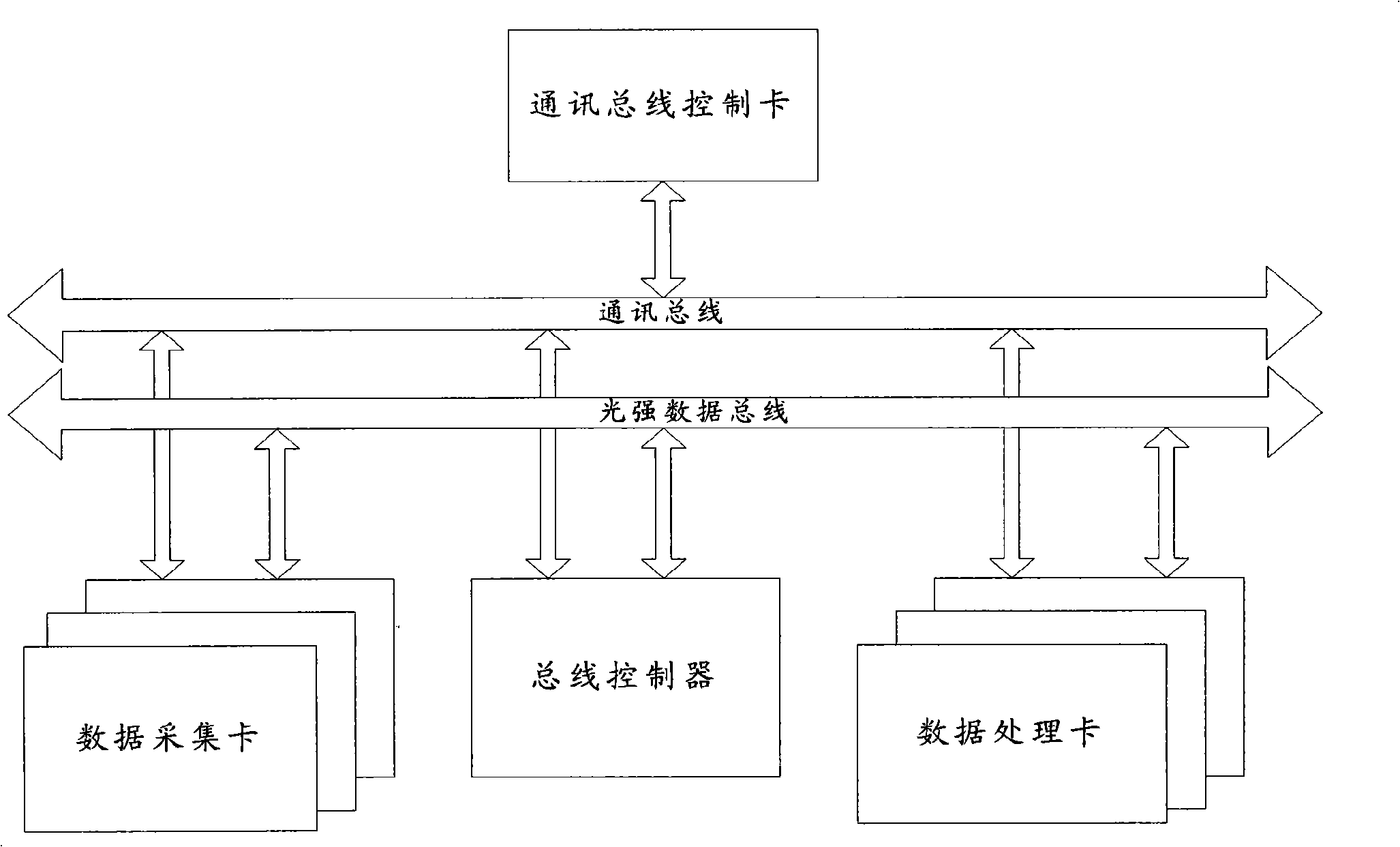

[0026] Such as figure 2 As shown, the storage device for lithography alignment data inspection of the present invention is a box part in the figure, at least including: A / D (analog-to-digital) sampling module for collecting data of off-axis alignment optical subsystems ;A write pointer, used to write the data collected by the A / D sampling module into the ring buffer queue; a read pointer, used to read the data in the ring buffer queue to the data output register, when the IDB bus sends light intensity data When applying, the data of the data output register is input to the data processing module (not shown); a ring buffer queue is used to cache light intensity data; a read-write pointer distance register is used to record the difference between read and write times, thereby Determine the reading and writing status of the ring buffer queue to avoid data overflow or invalid data misreading; a data output register is used to record the light intensity data in the ring buffer que...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com