Method and device for low-pressure processing of coal coking gas

A technology for coking gas and coal, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low pressure and high energy consumption, and achieve the effect of reducing energy consumption and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

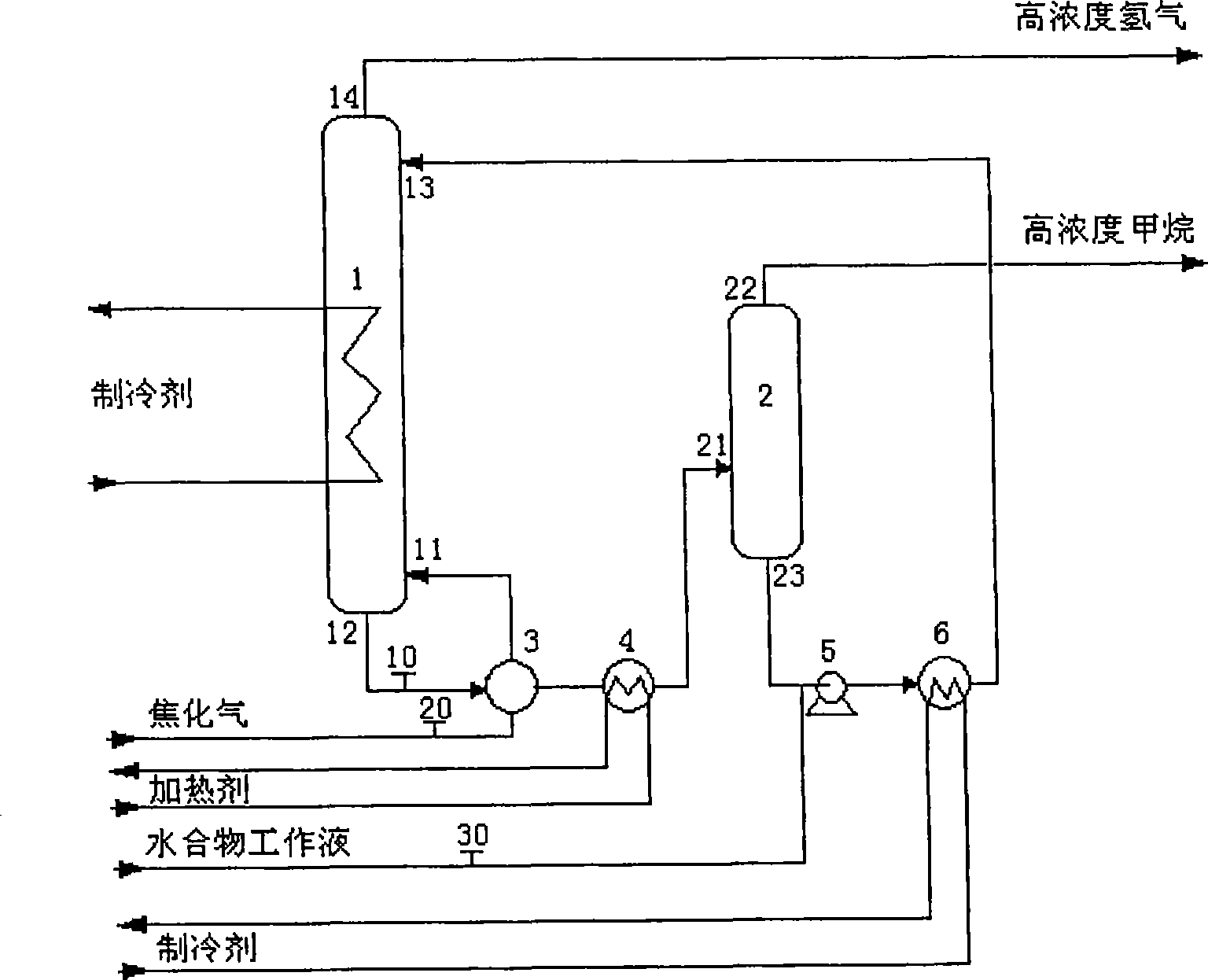

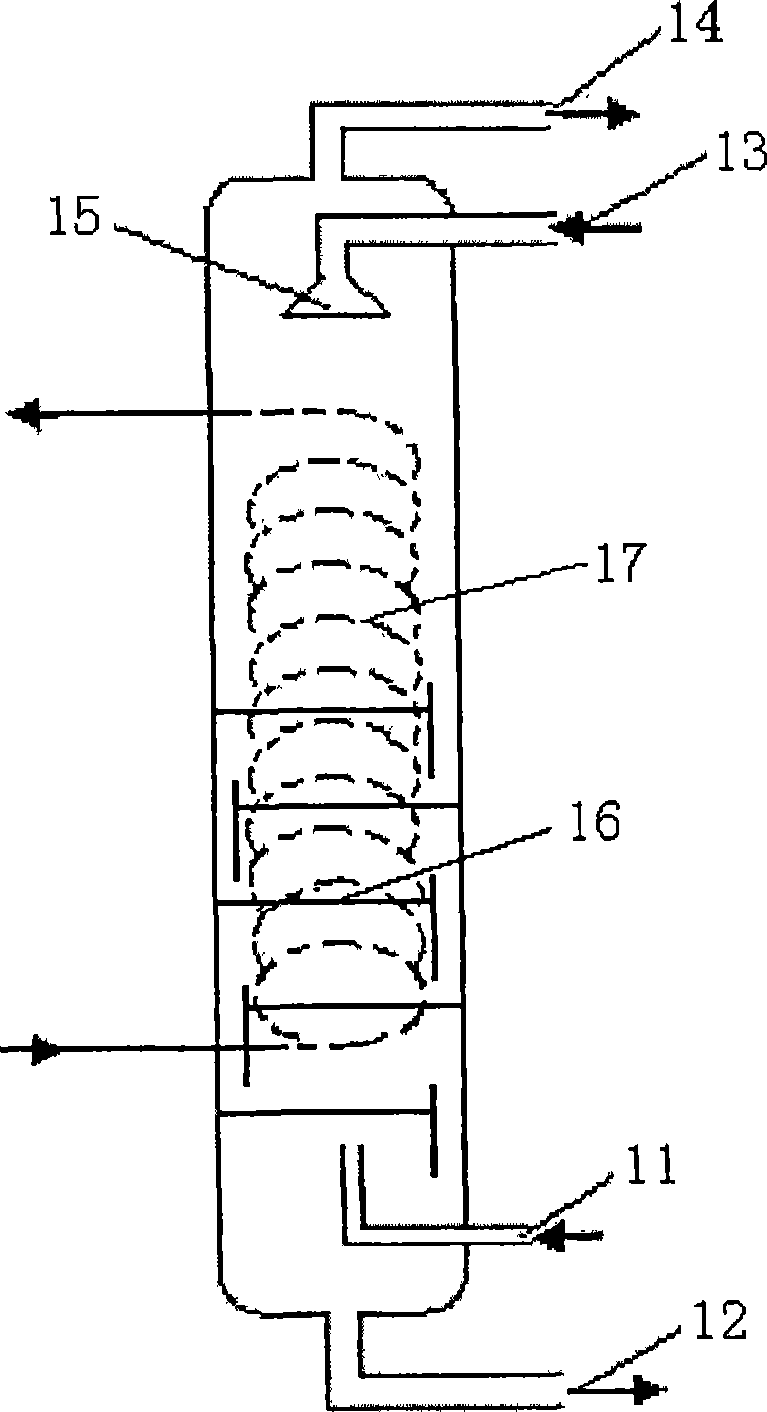

[0042] use figure 1 The technological process shown (wherein hydration reactor 1 adopts figure 2 The structure shown, no filter plate is set), and the simulated coking gas is separated to obtain high-concentration hydrogen and methane respectively. Wherein, the composition of the feed gas (equivalent to coking gas) entering the hydration reactor 1 is: H 2 (50.21mol%)+CH 4(49.79mol%); the operating temperature of the hydration reactor 1 is 3.0°C, and the operating pressure is 0.20MPa; the hydrate working fluid is an emulsion obtained by mixing the oil phase solution and the water phase solution at a volume ratio of 4:1, and the oil phase solution is Commercially available No. 20 diesel oil, the aqueous phase solution is an aqueous solution containing tetrahydrofuran (wherein the molar fraction of THF is 0.06), and the aqueous phase solution contains Span-60 with a molar fraction of 0.0128, and contains 500ppm of dodecyl Sodium benzenesulfonate; the volume ratio of the amoun...

Embodiment 2

[0044] use figure 1 The technological process shown (wherein hydration reactor 1 adopts figure 2 The structure shown, no filter plate is set), and the simulated coking gas is separated to obtain high-concentration hydrogen and methane respectively. Wherein, the composition of the feed gas (equivalent to coking gas) entering the hydration reactor 1 is: H 2 (59.16mol%)+CH 4 (40.84mol%); the operating temperature of hydration reactor 1 is 3.5°C, and the operating pressure is 0.96MPa; the hydrate working fluid is an oil phase solution and a water phase solution in a volume ratio of 4:1, and the oil phase solution is commercially available -No. 20 diesel oil, the aqueous phase solution is an aqueous solution containing tetrahydrofuran (wherein the molar fraction of THF is 0.06), and the aqueous phase solution contains Span-60 with a molar fraction of 0.0128, and contains 500ppm of dodecylbenzenesulfonate Sodium acid; the volume ratio of the amount of hydrate working liquid intr...

Embodiment 3

[0046] use figure 1 The technological process shown (wherein hydration reactor 1 adopts figure 2 The structure shown, no filter plate is set), and the simulated coking gas is separated to obtain high-concentration hydrogen and methane respectively. Wherein, the composition of the feed gas (equivalent to coking gas) entering the hydration reactor 1 is: H 2 (58.07mol%)+CH 4 (39.22mol%)+CO 2 (2.71mol%); the operating temperature of hydration reactor 1 is 3.8°C, and the operating pressure is 0.90MPa; the hydrate working fluid is an emulsion obtained by mixing the oil phase solution and the water phase solution at a volume ratio of 4:1, wherein the oil phase The solution is commercially available No.-20 diesel oil, the aqueous phase solution is an aqueous solution containing tetrahydrofuran THF (wherein the molar fraction of THF is 0.06), and the aqueous phase solution contains Span-60 with a molar fraction of 0.0128, and contains 500ppm of Sodium dialkylbenzene sulfonate; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com