High and low temperature resistant and hydrolysis resistant polyurethane monocomponent adhesive and preparation method thereof

A polyurethane single, high and low temperature resistant technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc. Good shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

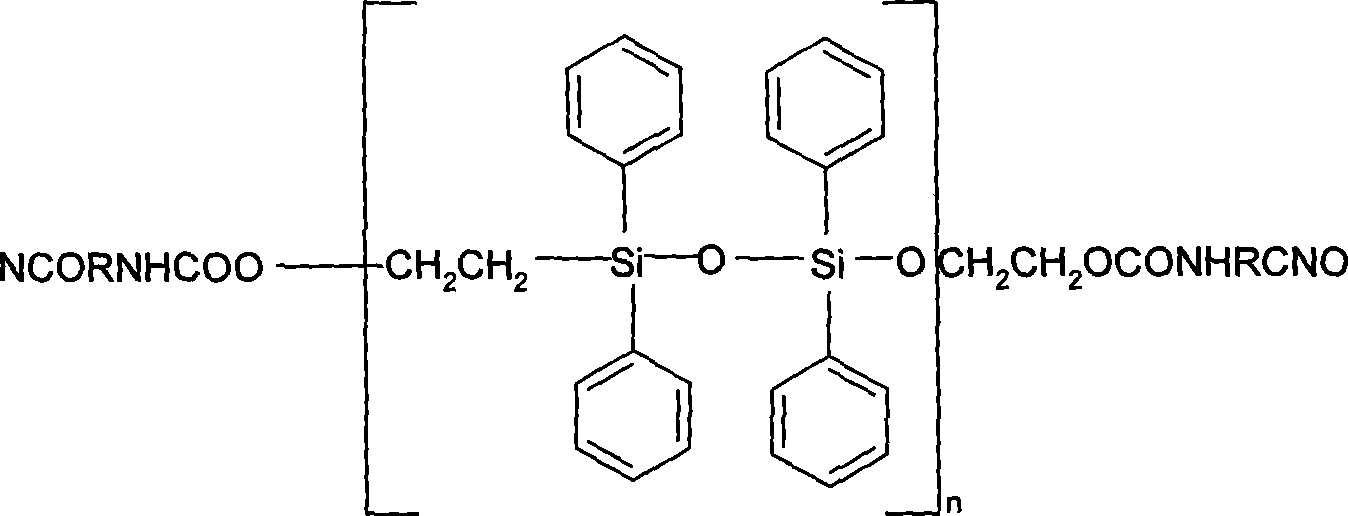

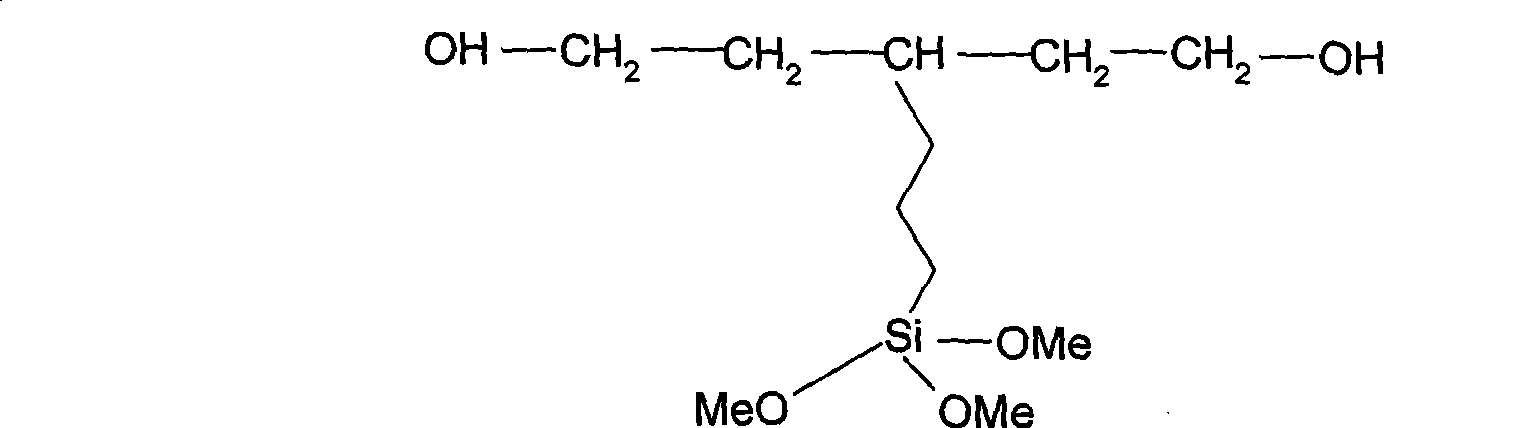

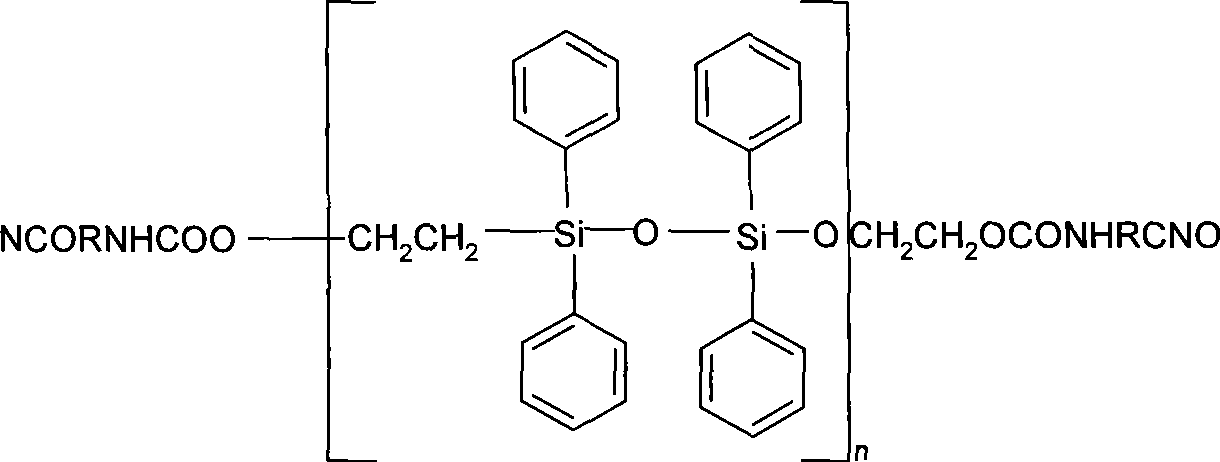

Method used

Image

Examples

Embodiment 1

[0022] The adhesive is prepared according to the following composition ratio (mass percentage content):

[0023] Silicone polyurethane modified prepolymer 40%

[0024] Solvent 10%

[0025] Chain extender 10%

[0026] Filling 40%

[0027] The preparation method of the adhesive is:

[0028] Mix the silicone polyurethane modified prepolymer with the chain extender, and after premixing for one hour, pour the remaining combinations into the already mixed reaction kettle, stir evenly, and pack. When the material is bonded, the moisture will solidify.

[0029] Example effect: low temperature resistance -200 degrees, high temperature 240 degrees, bonding shear force 21MPa., hydrolysis resistance resistance value 2.02×10 6 Ω.

Embodiment 2

[0031] The adhesive is prepared according to the following composition ratio (mass percentage content):

[0032] Silicone polyurethane modified prepolymer 45%

[0033] Solvent 10%

[0034] Chain extender 15%

[0035] Filling 30%

[0036] The preparation method of the adhesive is the same as in Example 1.

[0037] Example effect: low temperature resistance -200 degrees, high temperature 225 degrees, bonding shear force 20MPa, hydrolysis resistance resistance value 4.08×10 6 Ω.

Embodiment 3

[0039] The adhesive is prepared according to the following composition ratio (mass percentage content):

[0040] Silicone polyurethane modified prepolymer 47%

[0041] Solvent 15%

[0042] Chain extender 8%

[0043] Filling 30%

[0044] The preparation method of the adhesive is the same as in Example 1.

[0045] Example effect: low temperature resistance -200 degrees, high temperature 226 degrees, bonding shear force 24MPa, hydrolysis resistance resistance value 3.05×10 6 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond shear | aaaaa | aaaaa |

| Bond shear | aaaaa | aaaaa |

| Bond shear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com