High-power LED lamp and production process thereof

A technology for LED lamps and production processes, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc. Color index, versatility, uniform lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

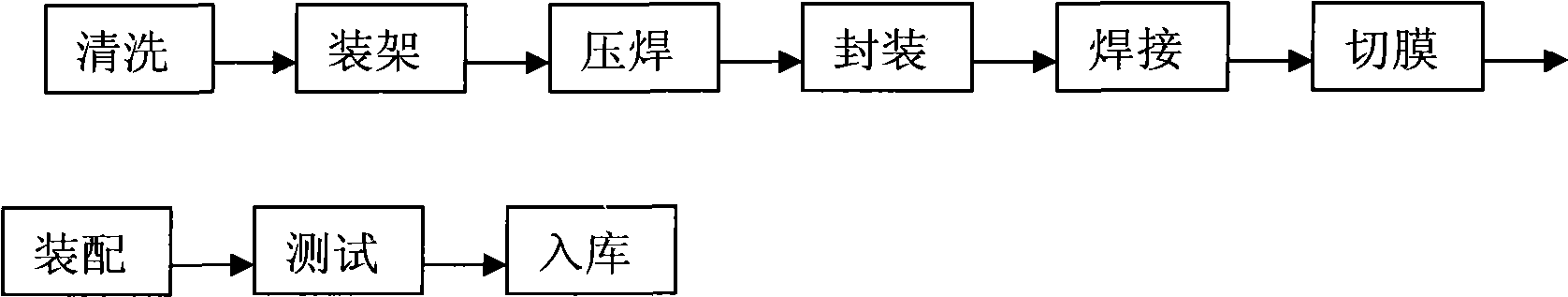

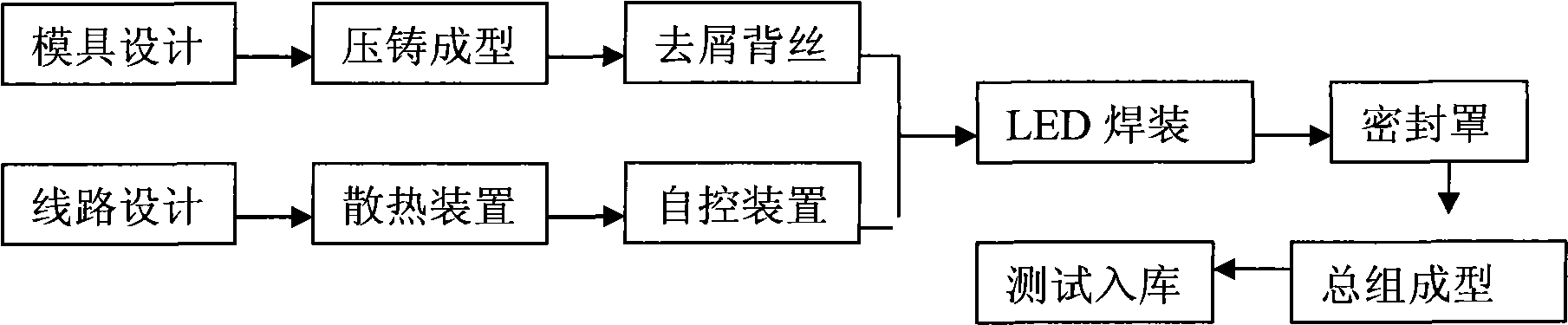

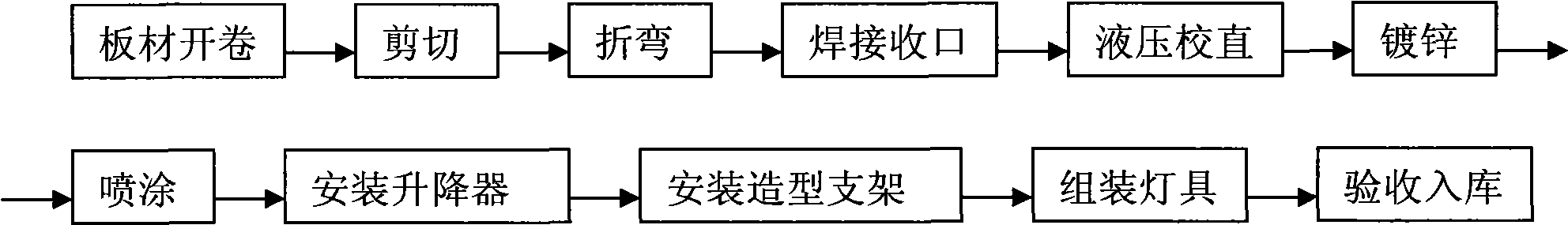

[0013] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a packaged optical system, a heat dissipation system and a drive system. The heat dissipation system adopts the natural heat dissipation method of air convection outside the lamp body. The drive system is an ultra-low voltage balanced voltage power supply system, and the lamp is separated from the power adapter. Including the packaging process of lamps, the production process of lamps and light sources, and the production process of lamps, the packaging process includes the following steps: cleaning, mounting, pressure welding, packaging, welding, film cutting, assembly, and testing; The production process of lamps and light sources includes mold design, die-casting, chip-removing back wire, circuit design, welding, sealing, and assembly; , spraying, installation of lifters, installation of modeling brackets, assembly.

[0014] The cleaning process includes ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com