Device for calibrating aircraft magnetic compasses

A technology for calibrating equipment and magnetic compass, which is applied in the direction of compass, measuring device, surveying and navigation, etc. It can solve the problems of affecting the measurement accuracy, low alignment accuracy, and increasing the uncertainty of measurement accuracy, so as to achieve accurate calibration work and improve Calibration accuracy, effect of labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

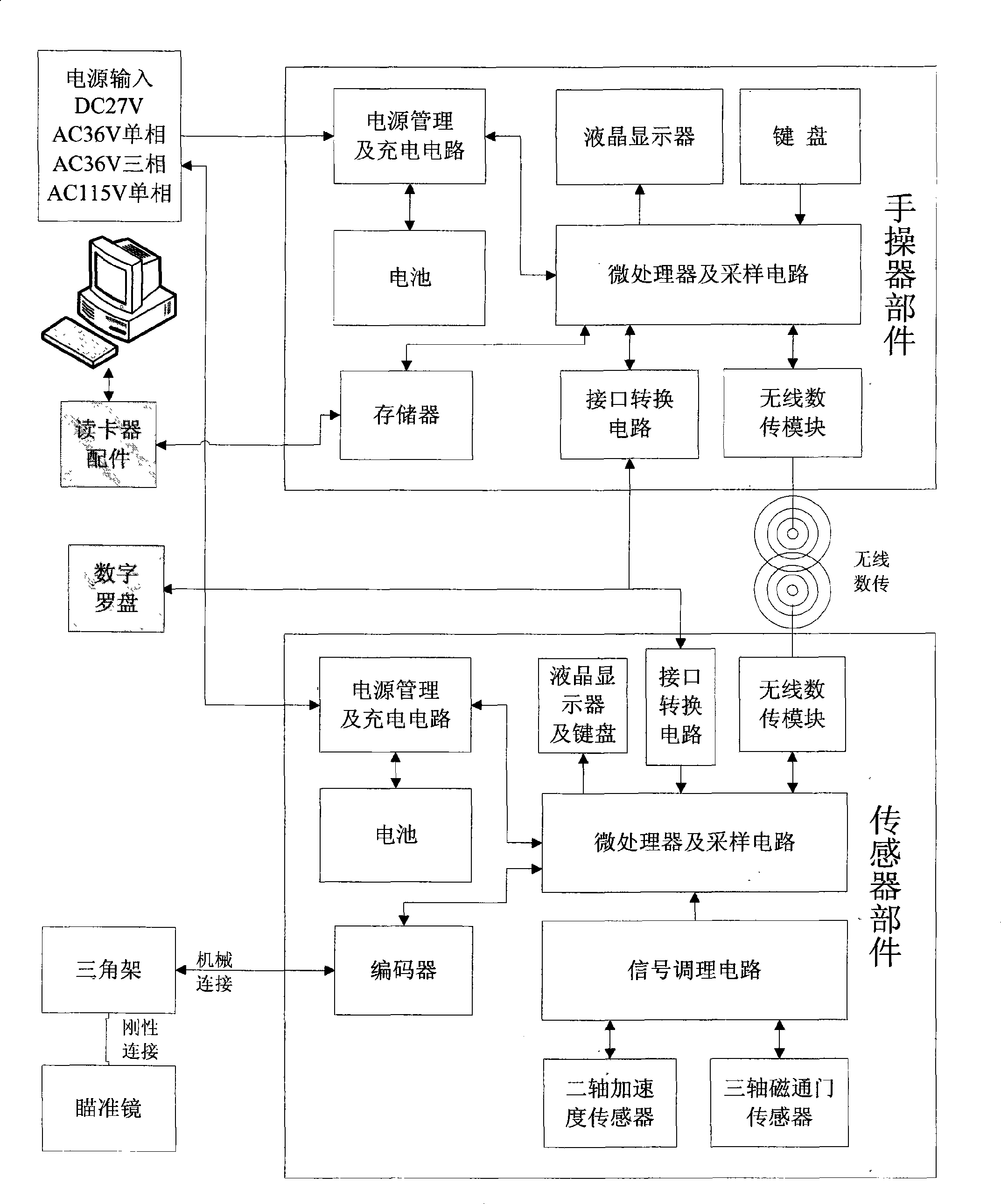

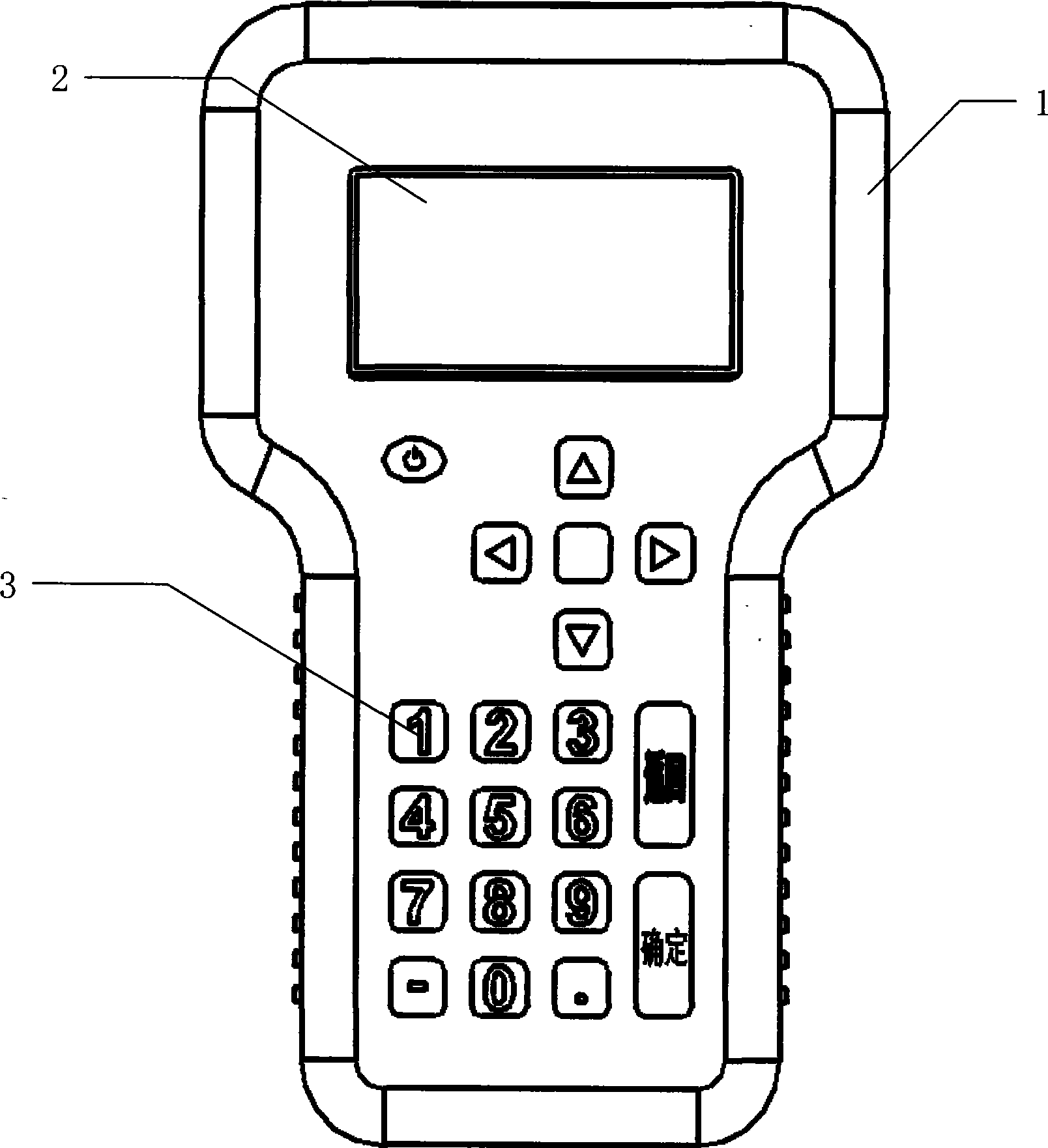

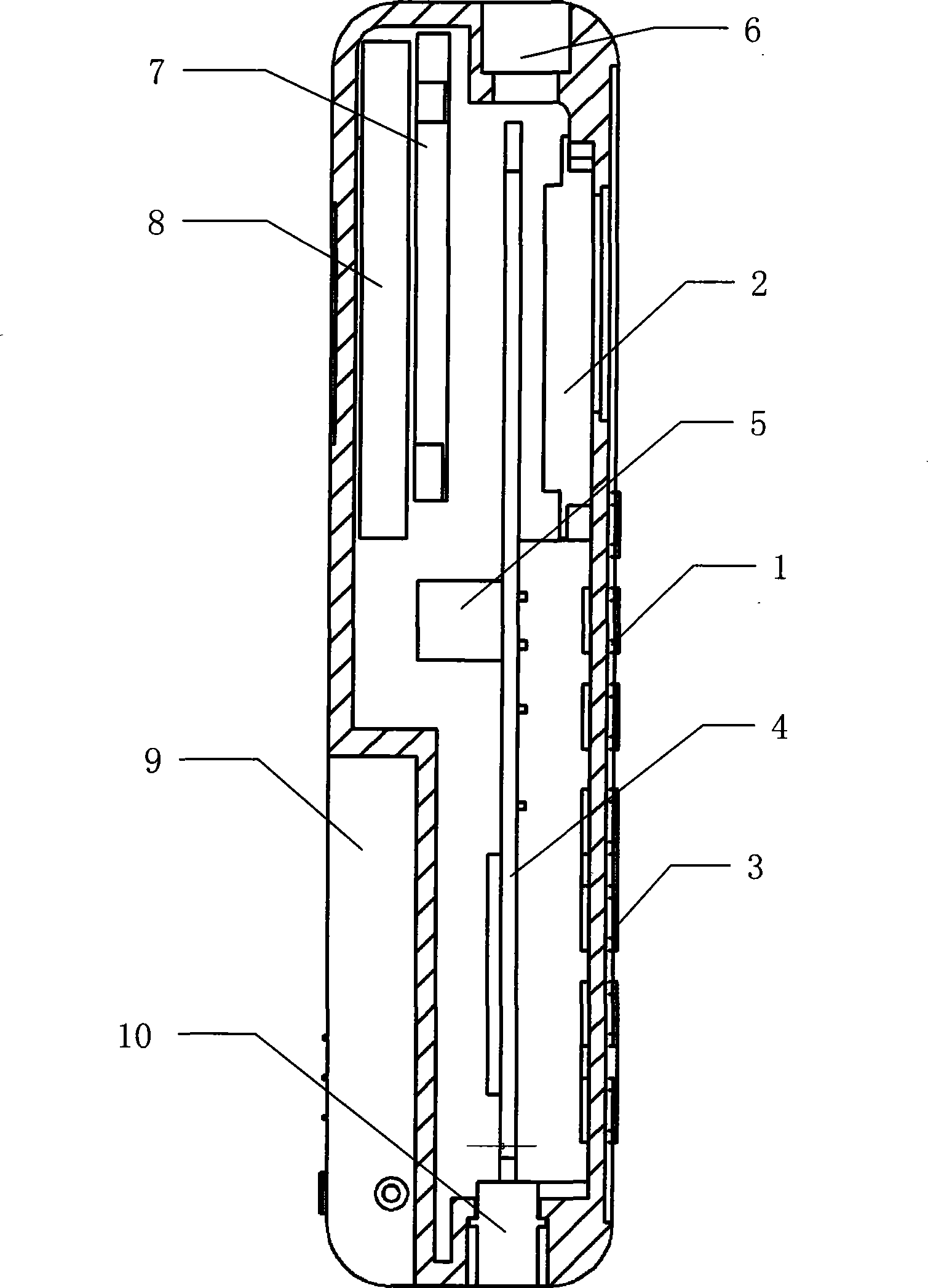

[0045] Such as figure 1 As shown, the present invention is composed of a hand-operated part and a sensor part. Among them, the sensor components are mainly composed of three-axis fluxgate sensor, two-axis acceleration sensor, encoder, sight, signal conditioning circuit, sampling circuit, microprocessor, wireless data transmission module, interface conversion circuit, liquid crystal display and keyboard, battery, Composed of power management circuit and charging circuit.

[0046] The specific connection relationship and working process of each component are as follows: the magnetic north axis of the three-axis fluxgate sensor is installed coincidentally with the horizontal axis of the two-axis acceleration sensor, and the axis perpendicular to the ground plane is installed coincidentally with the gravity axis. The three-axis fluxgate sensor sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com