Method for preparing electroformed nickel metallographic sample and displaying constitution

A technique for electroforming nickel and samples, applied in the field of preparing metallographic samples of electroforming nickel, can solve the problems of difficulty in corrosion, failure to mention the metallographic diagram of electroforming nickel, difficulties in preparing metallographic samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

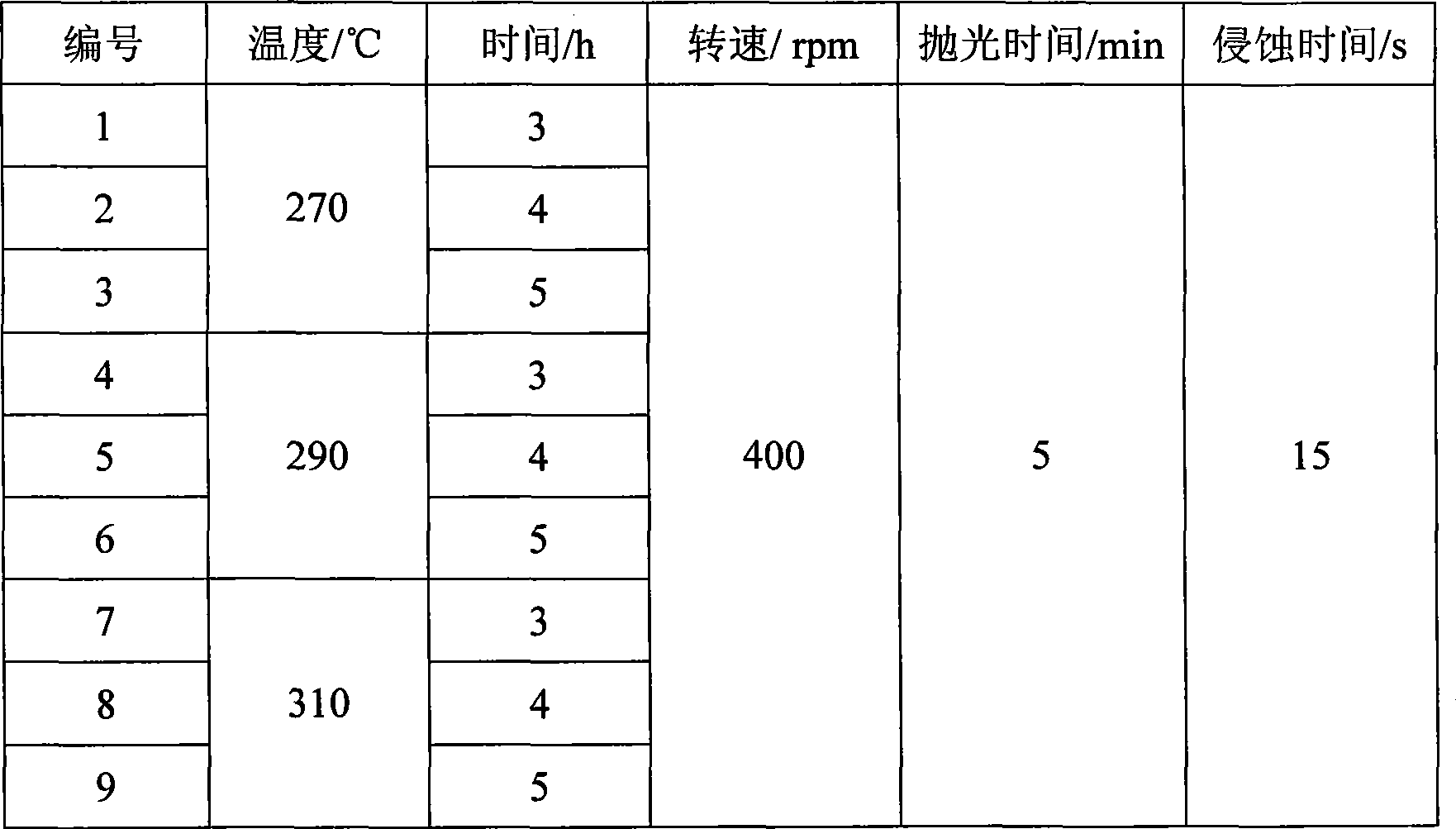

[0016] The electroformed nickel samples were placed in a vacuum furnace for annealing at temperatures of 270°C, 290°C, and 310°C, and times of 3h, 4h, and 5h. The specific groups are shown in Table 1:

[0017] Table 1 Test grouping

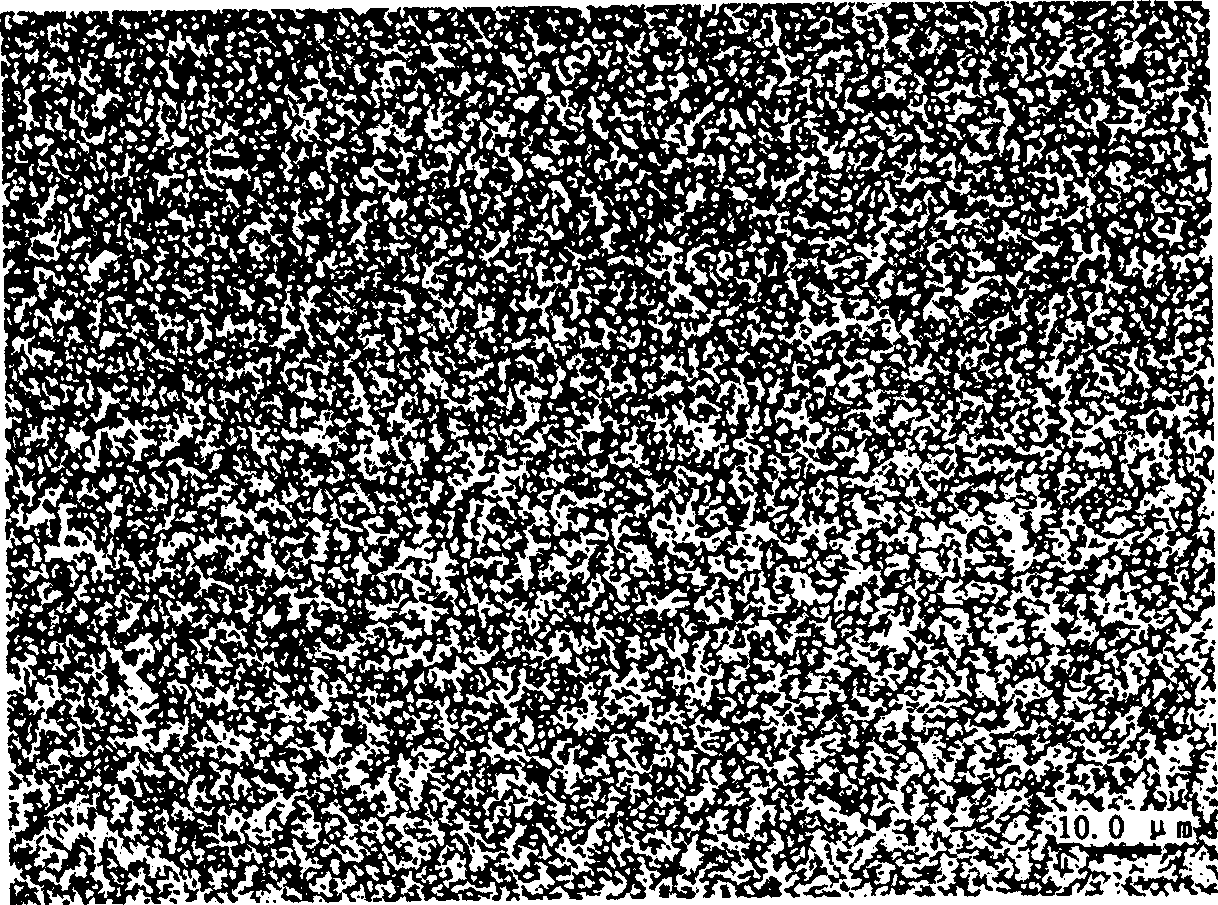

[0018]

[0019] The sample is roughly ground to 2000# silicon carbide water sandpaper, and water is used as lubricant. The force should be light, and the speed of the grinding disc should be slow, about 400rpm. Observe the surface of the sample with a microscope to determine the state of the ground surface.

[0020] Clean the roughly ground sample in an ultrasonic instrument, and polish it on a polishing flannelette. At this time, use 1 μm diamond polishing agent and ethanol as a lubricant. After polishing for about 5 minutes, observe the surface state under a microscope to confirm that the surface scratches are along one direction. Clean the ground sample in an ultrasonic instrument, replace it with a 0.5 μm diamond polishing agent, and use...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap