Dielectric-constant adjustable houghite-like membrane and preparation method thereof

A technology of dielectric constant and hydrotalcite, which is applied in the field of controllable preparation of inorganic functional thin films, can solve problems such as application reports of hydrotalcite thin film dielectric materials, and achieve strong binding force, wide practicability, and low dielectric constant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

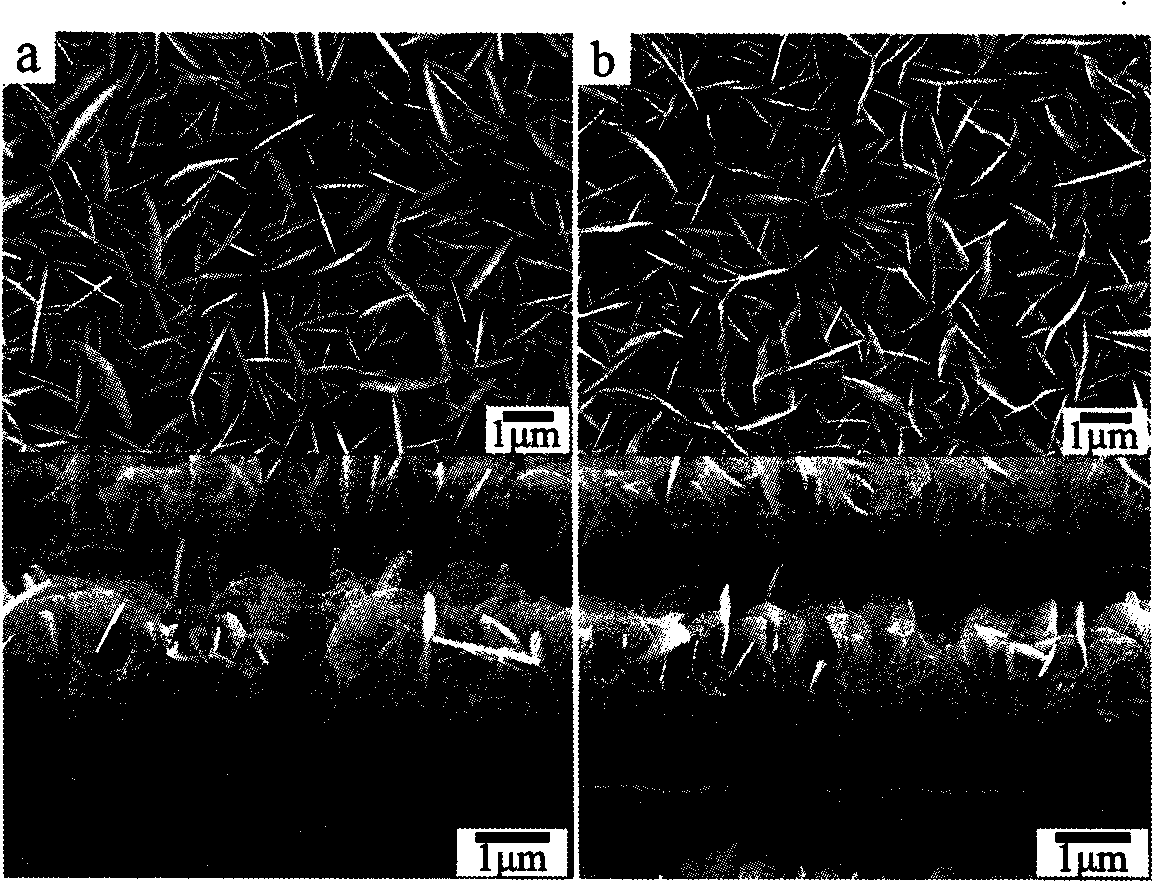

[0044] A. Select a flat Al sheet, first ultrasonically clean it with ethanol for 5 minutes, then ultrasonically clean it with water for 5 minutes to remove surface oil, and then place it in a sodium hydroxide solution with a concentration of 0.5 (wt)% for half a minute. When there are even air bubbles released on the surface of the substrate, take it out and rinse it with clean water, and set it aside;

[0045] B. Weigh 1.92gMg(NO 3 - ) 2 ·6H 2 O and 3.60g urea, dissolved in deionized water to make the concentration of magnesium ion is 0.075mol / L, urea and NO 3 - A 100mL mixed solution with a molar ratio of 4;

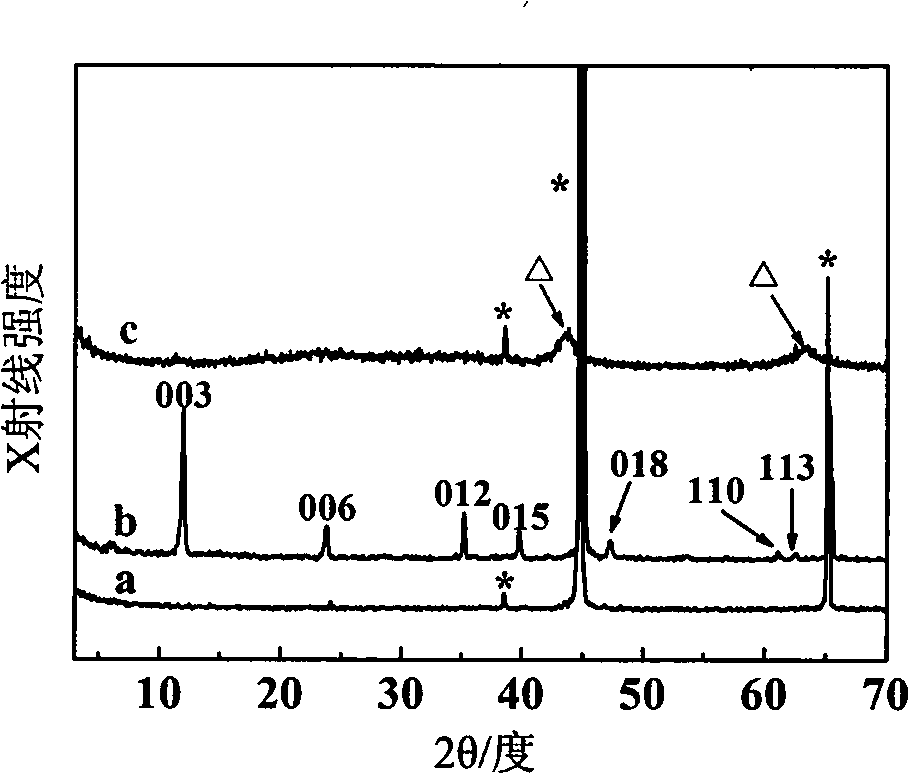

[0046] C. Put the substrate prepared in step A into the solution in step B, react at 90°C for 6 hours, take out the substrate, rinse it with deionized water, and dry it at room temperature to obtain the LDH film. The molecular formula of the hydrotalcite-like film is [Mg 2+ 1-x Al 3+ x (OH) 2 ] x+ ·(CO 3 2- ) x / 2 mH 2 O;

[0047] D. Calcining the LDH f...

Embodiment 2

[0049] A. Select a flat Al sheet, first ultrasonically clean it with ethanol for 5 minutes, then ultrasonically clean it with water for 5 minutes to remove surface oil, and then place it in a sodium hydroxide solution with a concentration of 0.5 (wt)% for half a minute. When there are even air bubbles released on the surface of the substrate, take it out and rinse it with clean water, and set it aside;

[0050] B. Weigh 1.28gMg(NO 3 - ) 2 ·6H 2 O and 2.40g urea, dissolved in deionized water to make the concentration of magnesium ion is 0.05mol / L, urea and NO 3 - A 100mL mixed solution with a molar ratio of 4;

[0051] C. Put the substrate prepared in step A into the solution in step B, react at 90°C for 6 hours, take out the substrate, rinse it with deionized water, and dry it at room temperature to obtain the LDH film. The molecular formula of the hydrotalcite-like film is [Mg 2+ 1-x Al 3+ x (OH) 2 ] x+ ·(CO 3 2- ) x / 2 mH 2 O;

[0052] D. Calcining the LDH fi...

Embodiment 3

[0054] A. Select a flat Al sheet, first ultrasonically clean it with ethanol for 5 minutes, then ultrasonically clean it with water for 5 minutes to remove surface oil, and then place it in a sodium hydroxide solution with a concentration of 0.5 (wt)% for half a minute. When there are even air bubbles released on the surface of the substrate, take it out and rinse it with clean water, and set it aside;

[0055] B. Weigh 2.56gMg(NO 3 - ) 2 ·6H 2 O and 6g urea, dissolved in deionized water to make the magnesium ion concentration 0.1mol / L, urea and NO 3 - A 100mL mixed solution with a molar ratio of 5;

[0056] C. Put the substrate prepared in step A into the solution in step B, react at 90°C for 6 hours, take out the substrate, rinse it with deionized water, and dry it at room temperature to obtain the LDH film. The molecular formula of the hydrotalcite-like film is [Mg 2+ 1-x Al 3+ x (OH) 2 ] x+ ·(CO 3 2- ) x / 2 mH 2 O;

[0057] D. Calcining the LDH film obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com