Multifunctional drag reduction agent of circulating water pipeline

A multi-functional, circulating water technology, applied in the field of fine chemicals, can solve the problems of high raw material prices, corrosion and lack of long-term stability data, etc., and achieve the effects of short investment recovery period, obvious drag reduction and energy saving effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

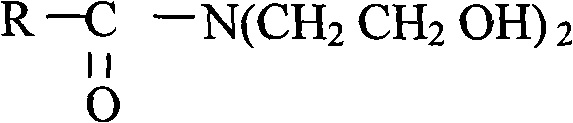

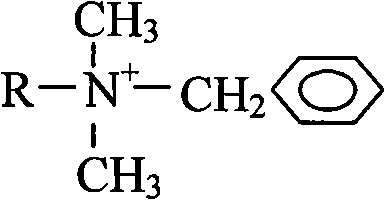

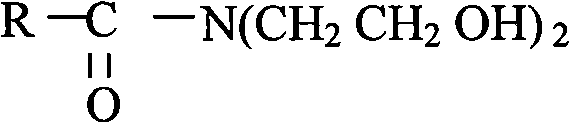

Method used

Image

Examples

Embodiment 1

[0040] In a 250ml beaker, take by weighing commercially available industrial dodecyl dimethyl benzylamine chloride (content 40%) 62.5g, commercially available industrial coconut acid diethanolamide 10.0g, commercially available industrial hydroxyethylidene diphosphine Sodium bicarbonate (content 70%) 7.1g and water 20.4g, stirring and dissolving, obtain 100g 40% multifunctional drag reducer. Weigh 1.0g, 2.0g, 3.0g, 4.0g and 5.0g and dissolve them in 1000ml tap water respectively, and measure the viscosity with NDJ-79 rotary viscometer at 750rpm at room temperature (25°C) for preliminary evaluation, 5 times The test results are shown in Table 1. When the drag reducer is above 1.2g / L, the viscosity of the aqueous solution decreases. It can be seen that when the drag reducer concentration is 1.2g / L, the concentration of drag reducer micelles is reached. The added concentration of the multifunctional drag reducer at room temperature is initially selected as 1.2g. / L.

[0041] Ta...

Embodiment 2

[0044] In a 2500ml beaker, take by weighing commercially available industrial dodecyl dimethyl benzylamine chloride (content 40%) 450g, commercially available industrial coconut acid diethanolamide 200g, commercially available industrial sodium hydroxyethylidene diphosphonate (content 70%) 27g, organic silicon defoamer 1.0g and water 322g, stirring and dissolving, obtain 1000g 40% multifunctional drag reducer. Performance evaluation of the drag reducer was performed on a device with a circulating water volume of 200L, a test pipe diameter of DN20, and a test pipe length of 6000mm. Add 200g of the prepared multifunctional drag reducer at room temperature (25°C) at a circulating water flow rate of 3.2m / s to measure the drag reduction rate, and then add 200g of the drag reducer each time to measure the drag reduction rate. The results of 5 tests As shown in table 2.

[0045] Table 1 Effect of drag reducer concentration on drag reduction rate

[0046] serial number

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com