Thin film transistor

A thin film transistor and channel layer technology, applied in transistors, semiconductor devices, electrical components, etc., can solve problems such as large drain currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

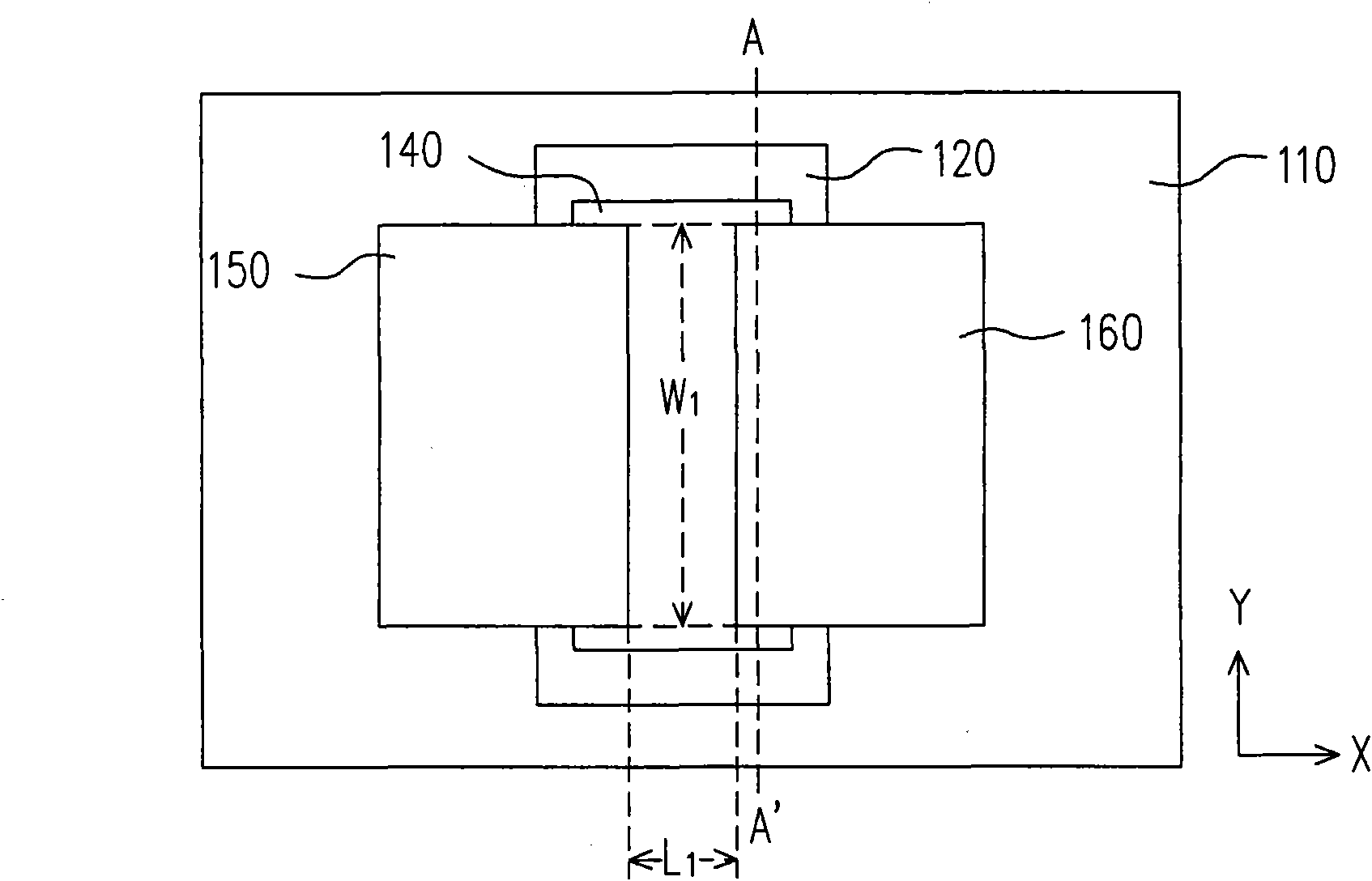

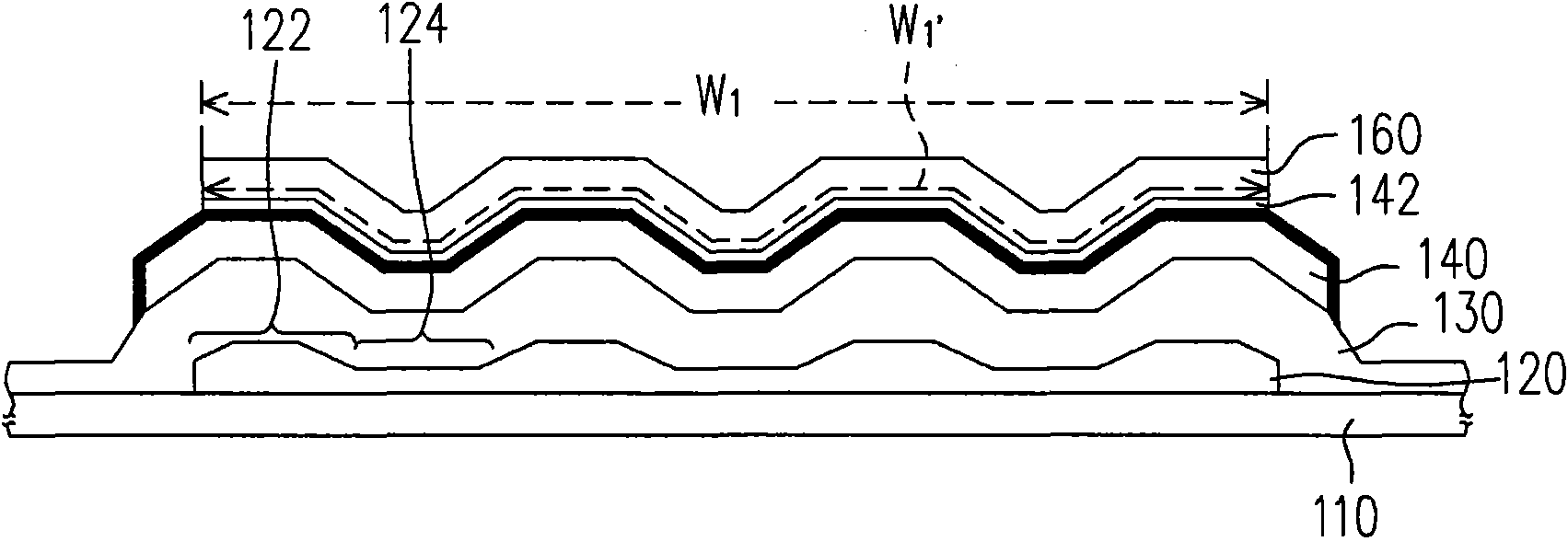

[0045] Figure 1A It is a schematic diagram of a thin film transistor according to an embodiment of the present invention. Figure 1B yes Figure 1A Sectional view of the structure along section line A-A'. in the text, Figure 1A The Y direction is the direction extending along the channel width W1, which is defined as the longitudinal direction, and the X direction is the direction extending along the channel length L1, which is defined as the lateral direction.

[0046] Please also refer to Figure 1A and Figure 1B . The TFT includes a gate 120 , a gate insulating layer 130 , a channel layer 140 , a source 150 and a drain 160 . Wherein, the gate 120 is disposed on a substrate 110 . The substrate 110 may be a transparent substrate 110 such as glass or quartz. The gate 120 can be fabricated by depositing a metal material on the substrate 110 by, for example, physical vapor deposition (PVD), and then patterning the metal material through a photomask process. The above-men...

no. 2 example

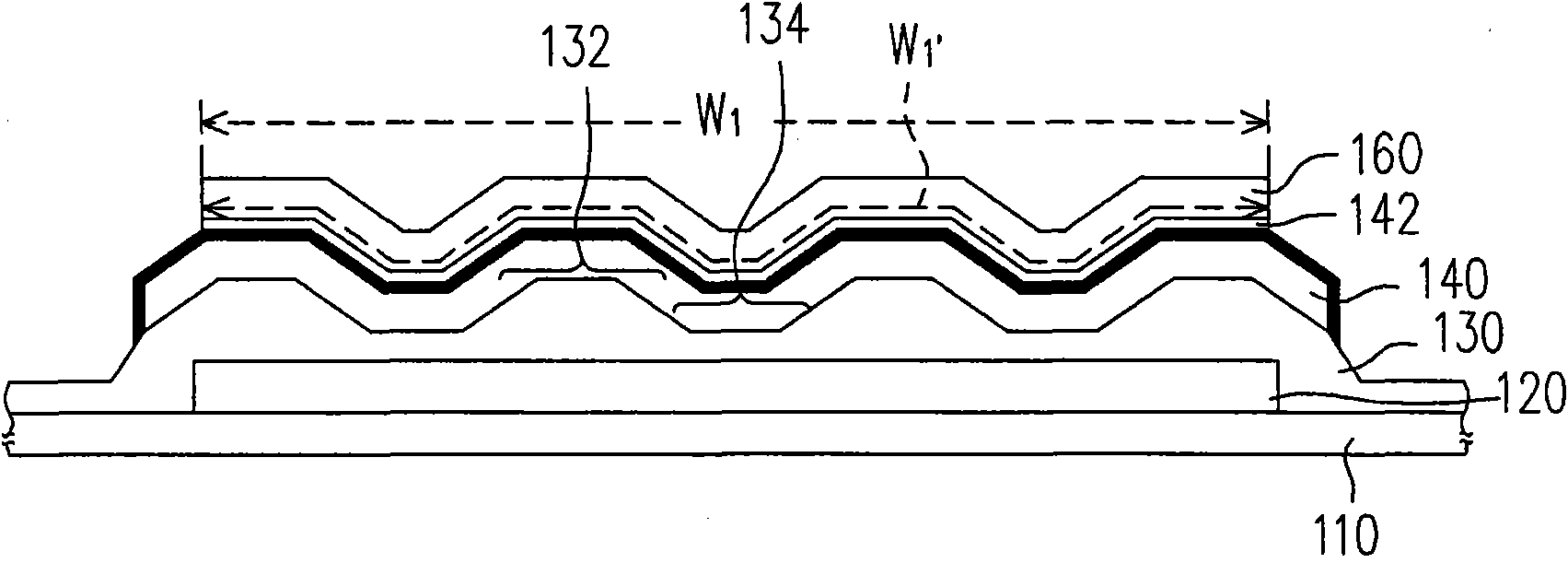

[0051] Figure 2A It is a schematic diagram of a thin film transistor according to another embodiment of the present invention, Figure 2B for Figure 2A Sectional view of the structure along section line B-B'. Please also refer to Figure 2A and Figure 2B , the thin film transistor includes a gate 120 , a gate insulating layer 130 , a channel layer 140 , a source 250 and a drain 260 . The gate 120 is disposed on a substrate 110 , and the gate insulating layer 130 covers the gate 120 . The substrate 110 may be a transparent substrate 110 such as glass or quartz. The gate 120 can be fabricated by depositing a metal material on the substrate 110 by, for example, physical vapor deposition (PVD), and then patterning the metal material through a photomask process. The above-mentioned metal materials can be selected from low-resistance materials such as aluminum, gold, copper, molybdenum, chromium, titanium, aluminum alloy or molybdenum alloy.

[0052] In addition, the gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com