Method for microwave drying of sodium chloride

A microwave drying and sodium chloride technology, which is applied in the direction of alkali metal chloride, drying solid materials, drying, etc., can solve the problems of backward drying equipment technology, lower recovery rate, and long drying cycle, so as to avoid the attenuation of microwave output power Phenomenon, improving the high quality rate and qualified rate, and improving the effect of dynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

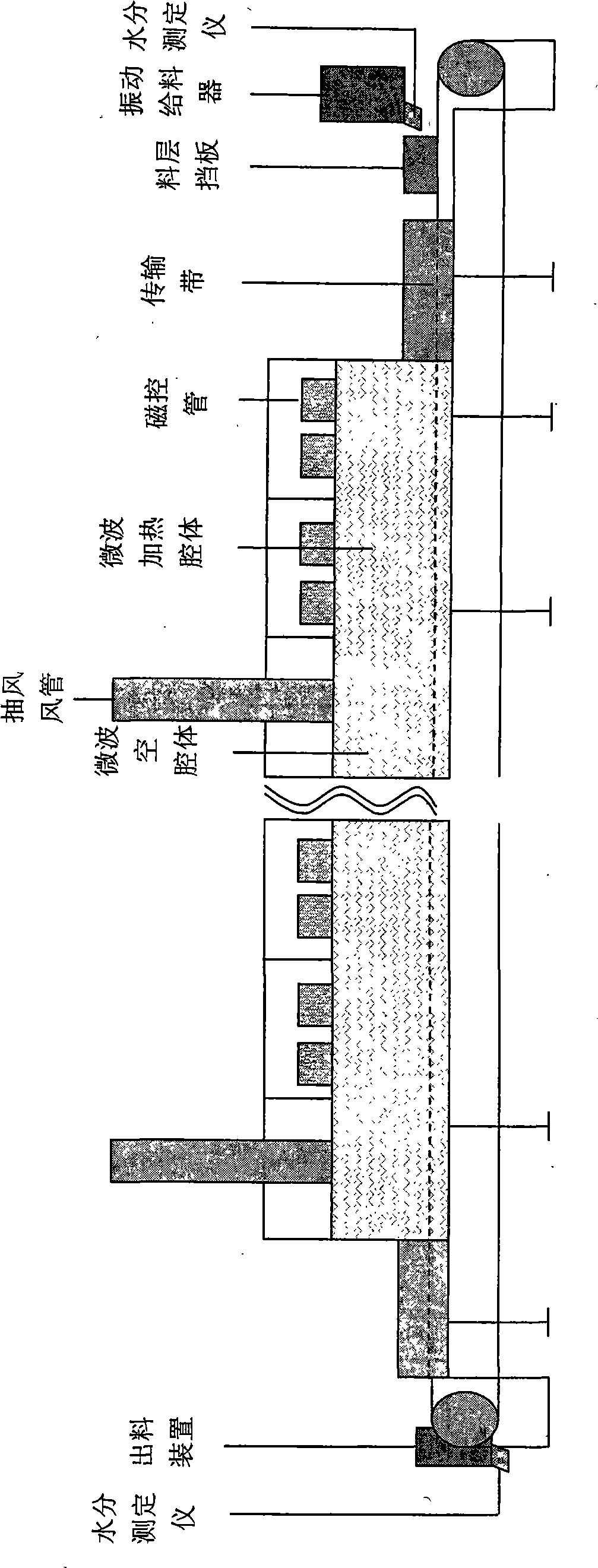

Image

Examples

Embodiment 1

[0023] Implementation example 1: take sodium chloride with a moisture content of 1.0% by mass as the drying object, the microwave output power used is 12kW, and one cavity is set behind every two microwave cavities, and each cavity is equipped with six magnetrons , the power of each magnetron is 1.5kW, the frequency is 2450MHz, the thickness of the control material layer is 2cm, and the air volume is 1247m 3 / h, the speed of the conveyor belt is 1.5m / min, the temperature of sodium chloride in the microwave cavity is 65 ° C, the continuous 2h of feeding and discharging, the moisture of sodium chloride at the discharge port is all lower than 0.5 mass%, and the average is 0.48%. By calculation, the dehydration amount of microwave drying sodium chloride is 0.41kg / kW·h, that is, the power consumption required to dry each ton of material is 42kW·h.

Embodiment 2

[0024] Implementation example 2: take sodium chloride with a moisture content of 3.5% by mass as the drying object, the microwave output power used is 18kW, and one cavity is set behind every two microwave cavities, and each cavity is equipped with six magnetrons , the power of each magnetron is 1.5kW, the frequency is 2450MHz, the thickness of the material layer is 1.5cm, and the air volume is 2250m 3 / h, the speed of the conveyor belt is 1m / min, and the temperature of sodium chloride in the microwave cavity is 70°C at this time, through continuous 4h feeding and discharging, the moisture of sodium chloride at the discharge port is all lower than 0.5 mass%, with an average of 0.46 %, by calculation, the dehydration amount of microwave drying sodium chloride is 0.38kg / kW·h, that is, the power consumption required to dry each ton of material is 8kW·h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com