Method for producing low carbon chemical ethanol from C6 sugar alcohol

A technology for chemical alcohols and sugar alcohols, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems that process data and process route products do not meet the requirements of industrialized production, and achieve novel production routes, Unique process conditions, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

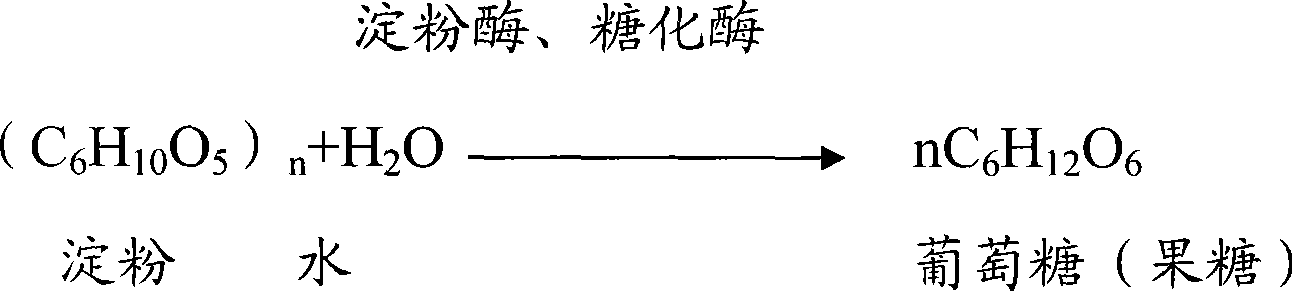

[0016] The raw material that the production method of chemical industry alcohol of the present invention adopts is C 6 Sugar alcohol, which can be commercially available C 6 Sugar alcohols can also use grains as raw materials to produce starch by conventional methods, generate glucose through liquefaction and saccharification, and then produce the C used in the present invention by hydrogenation. 6 sugar alcohol.

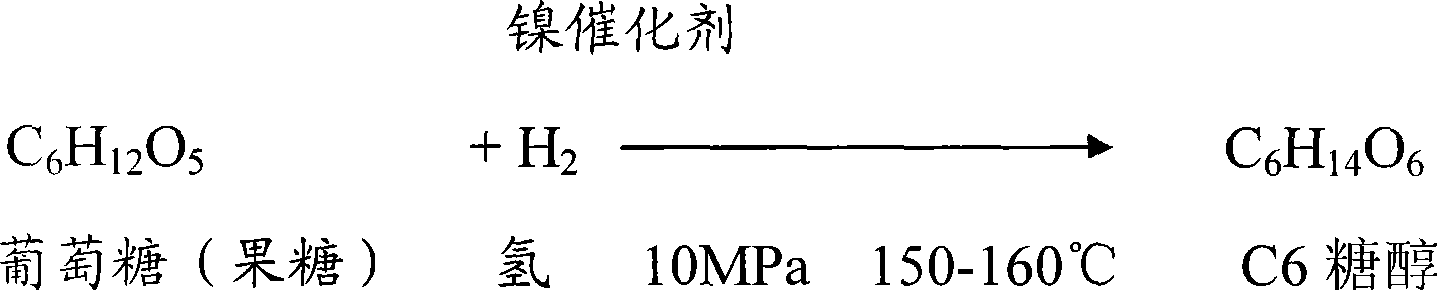

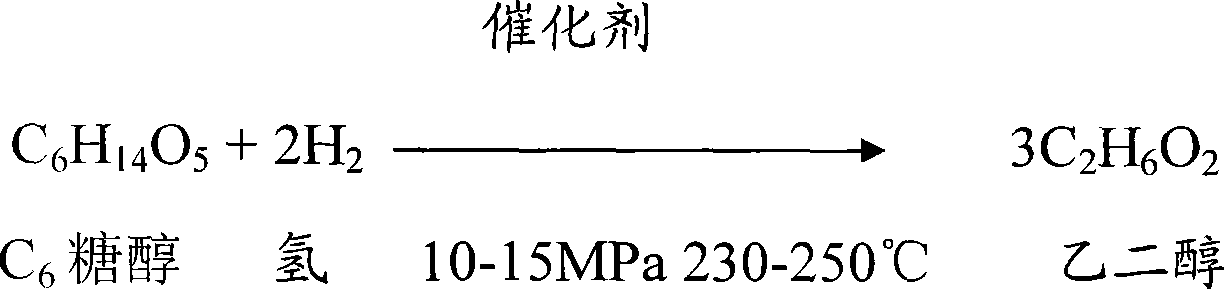

[0017] The basic raw material of the present invention is starch. For example, after converting corn into starch milk, it can be directly liquefied and saccharified to produce glucose. Generate glucose solution, and produce liquid C by high-pressure hydrogenation reaction under the action of nickel catalyst 6 Sugar alcohol, under the action of cracking catalyst, C 6 Sugar alcohols are further hydrocracked to generate the chemical alcohols.

[0018] The reaction formula is listed below to illustrate:

[0019] 1. Glucose production

[0020]

[0021] 2. Produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com