Simple method for preparing sphere analogous alpha-zirconium phosphate

A zirconium phosphate, spherical-like technology, which is applied in the field of simple preparation of spherical-like zirconium phosphate materials, can solve the problems of long process steps, time-consuming, pollution, etc., and achieve easy operation, good repeatability, and simple molding equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

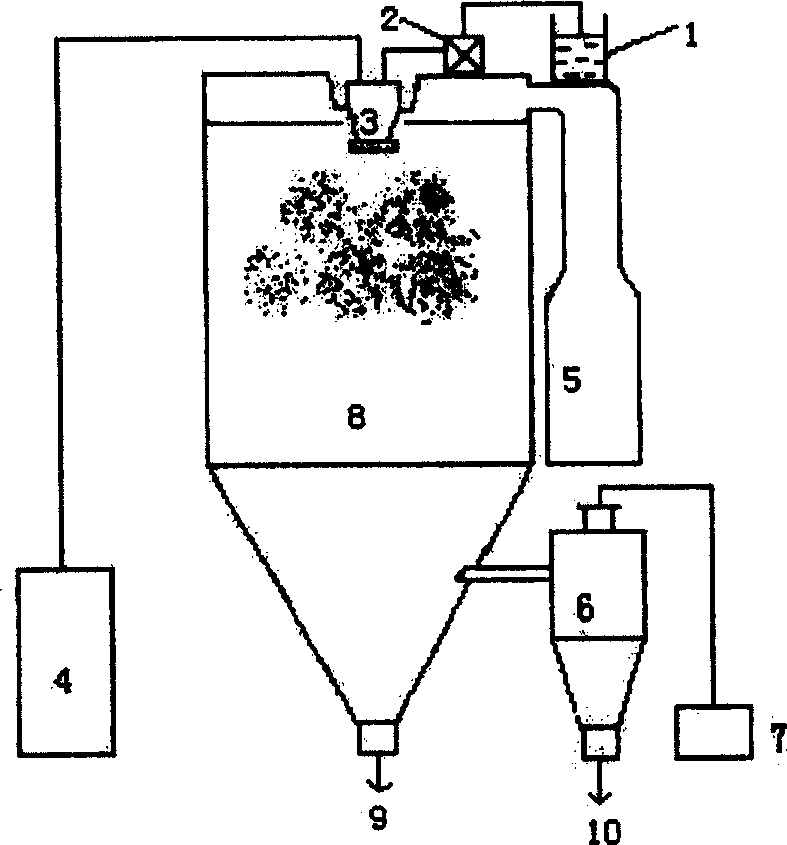

Method used

Image

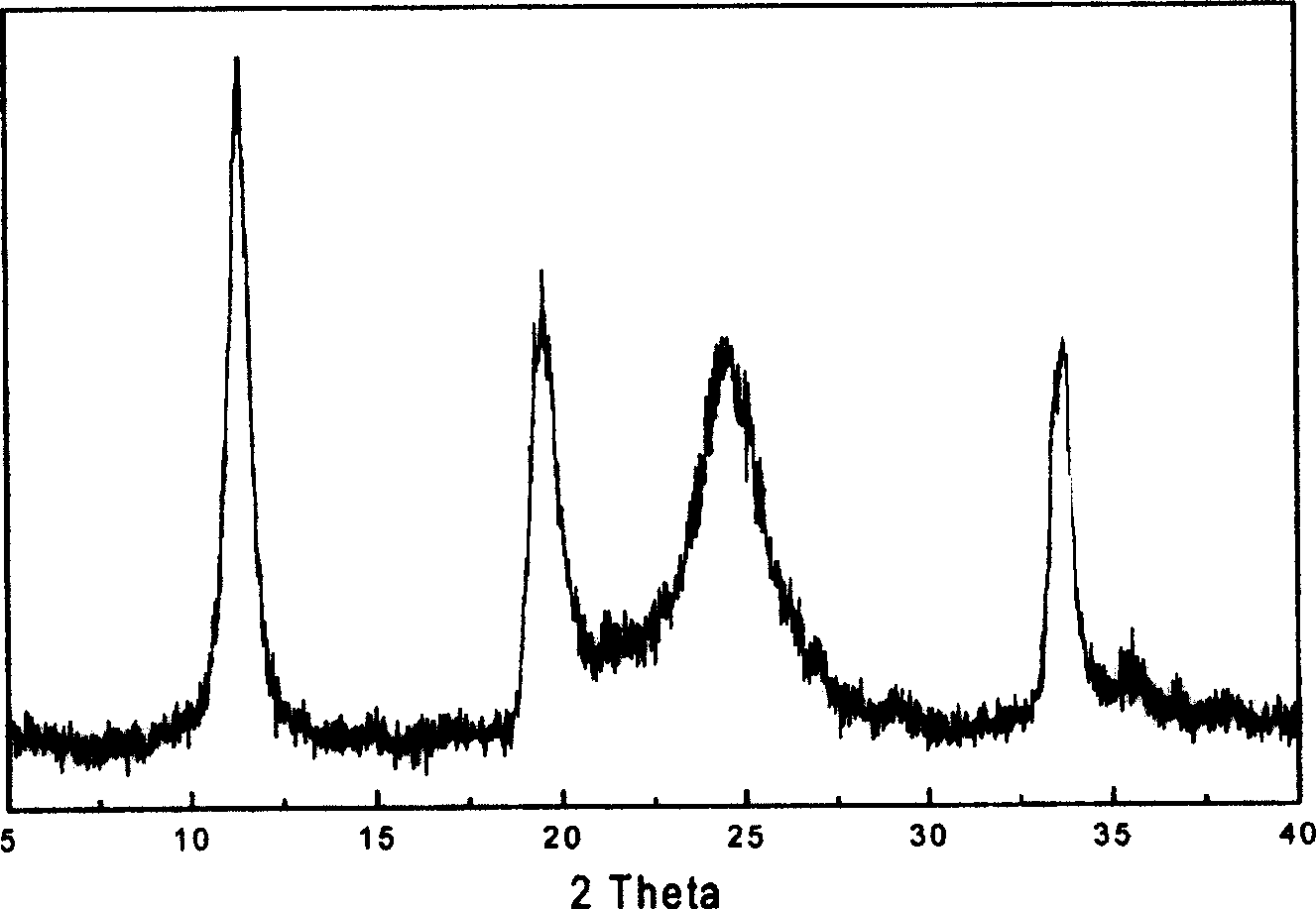

Examples

Embodiment 1

[0027] A: 4.5g ZrOCl 2 ·8H 2O is dissolved in concentration and is made into 125ml solution in the hydrochloric acid solution of 2mol / L, and the phosphoric acid that molar concentration is 4mol / L and the hydrochloric acid that molar concentration is 2mol / L are mixed according to volume ratio and prepare 125ml mixed acid solution in the ratio of 3 to 5; ZrOCl 2 The salt solution and the mixed acid solution are added to the total back-mixed liquid film reactor at the same time, the slit width between the rotor and the stator of the reactor is adjusted to 0.02mm, the working voltage is 100V, and the rotor speed is 4000rpm, and the obtained mixed slurry is added to the crystallization Stir in the kettle, keep the temperature of the mixed slurry in the kettle at 95-105°C for reflux crystallization for 6 hours, and obtain zirconium phosphate gel;

[0028] Add it into 80ml of 85% phosphoric acid solution by mass, mix evenly, stir and reflux for 16 hours at 90°C, separate and wash t...

Embodiment 2

[0033] A: 5.5g ZrOCl 2 ·8H 2 O is dissolved in concentration and is made into 125ml solution in 2mol / L hydrochloric acid solution, and the phosphoric acid that molar concentration is 4mol / L and the hydrochloric acid that molar concentration is 2mol / L are mixed according to the ratio of 1 to 1 according to volume ratio and prepare 125ml mixed acid solution; ZrOCl 2 The salt solution and the mixed acid solution were added to the total back-mixed liquid film reactor at the same time, the slit width between the rotor and the stator of the reactor was adjusted to 0.03mm, the working voltage was 90V, and the rotor speed was 4000rpm, and the obtained mixed slurry was added to the crystallization Stir in the kettle, keep the temperature of the mixed slurry in the kettle at 95-105°C for reflux crystallization for 6 hours, and obtain zirconium phosphate gel;

[0034] Add it into 50ml of 85% phosphoric acid solution by mass and mix evenly, stir and reflux for 3 days at 80°C, centrifuge...

Embodiment 3

[0038] A: 7gZrOCl 2 ·8H 2 O is dissolved in a hydrochloric acid solution with a concentration of 2mol / L to prepare a 125ml solution, and phosphoric acid with a molar concentration of 4mol / L and hydrochloric acid with a molar concentration of 2mol / L are mixed according to the volume ratio of 7 to 5 to prepare 125ml of mixed acid solution ; ZrOCl 2 The salt solution and the mixed acid solution were placed in a fully back-mixed liquid film reactor, the slit width between the reactor rotor and the stator was adjusted to 0.02mm, the working voltage was 100V, and the rotor speed was 4000rpm, and the obtained mixed slurry was added to the crystallization Stir in the kettle, keep the temperature of the mixed slurry in the kettle at 95-105°C for reflux crystallization for 7 hours, and obtain zirconium phosphate gel;

[0039] Add it into 100ml of 85% phosphoric acid solution by mass, mix evenly, and stir and reflux for 4 days at 70°C to obtain α-zirconium phosphate raw powder.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com