Sphere analogous alpha-zirconium phosphate and preparing method thereof

A technology of zirconium phosphate and spherical shape, which is applied in the field of preparation of spherical zirconium phosphate materials, can solve the problem of less α-zirconium phosphate, and achieve the effects of easy operation, mild synthesis conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

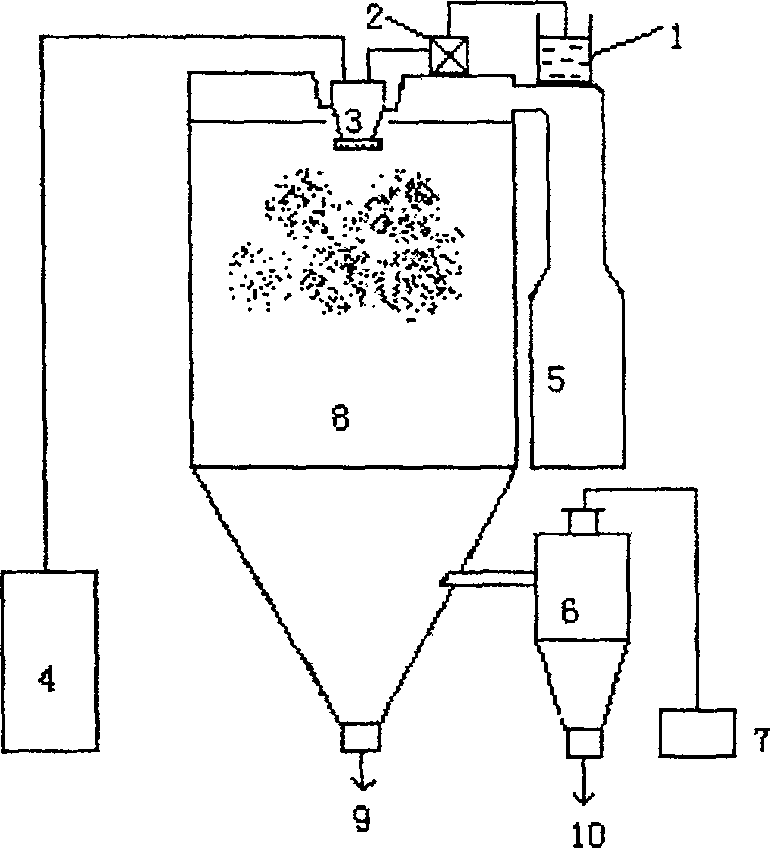

Method used

Image

Examples

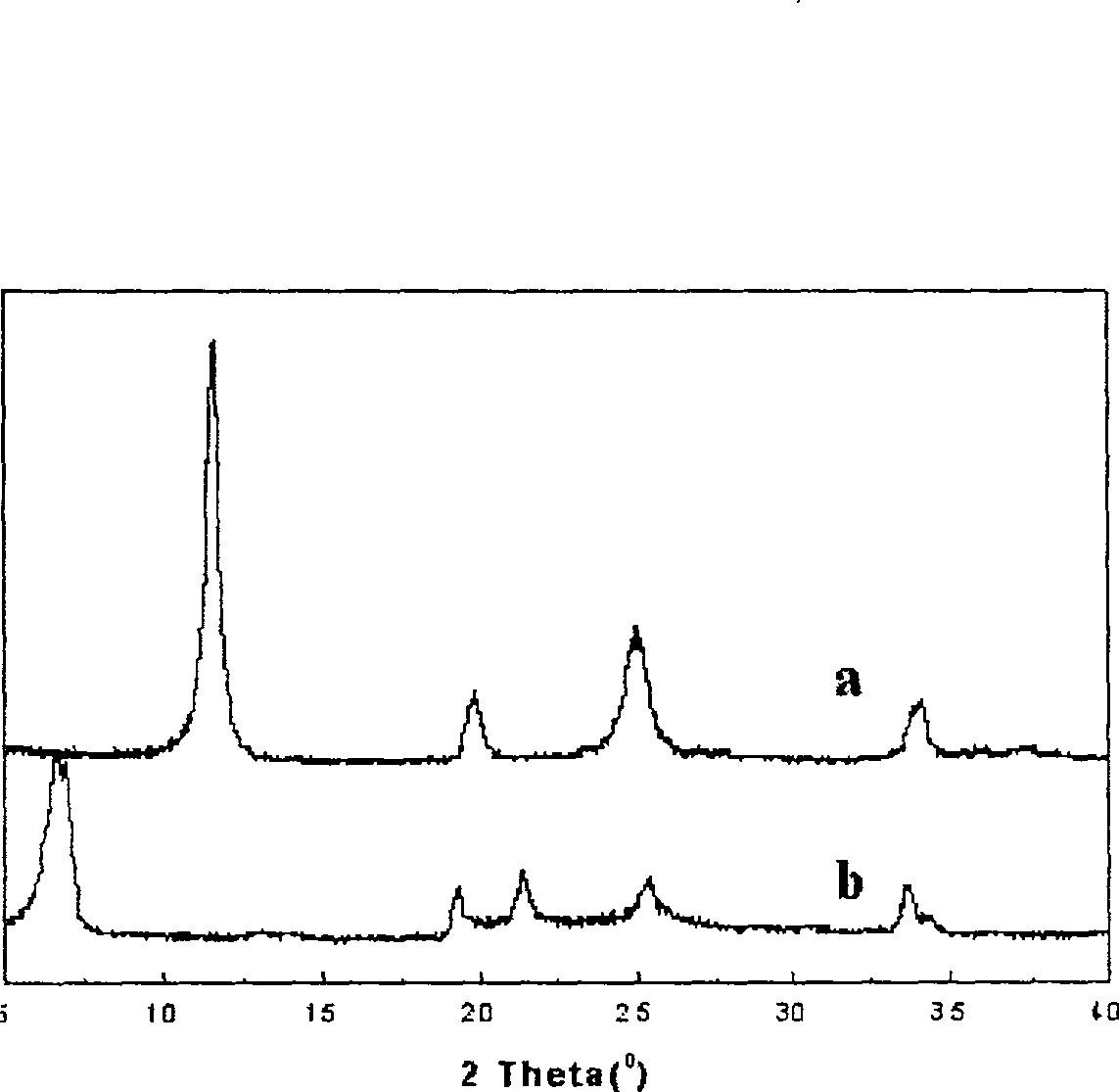

Embodiment 1

[0028] 4.5gZrOCl 2 ·8H 2 O is dissolved in 125ml concentration of 2mol / L hydrochloric acid solution, and the molar concentration is 4mol / L phosphoric acid 15ml and the molar concentration is 2mol / L hydrochloric acid 25ml is mixed to prepare mixed acid solution; ZrOCl 2 The salt solution was slowly added dropwise into the mixed acid solution to obtain a zirconium phosphate gel; it was added into 80ml of 85% phosphoric acid solution by mass and mixed uniformly, stirred and refluxed for 16 hours at a temperature of 90°C, separated and dried. That is, the original powder of α-zirconium phosphate is obtained.

[0029] Dissolve 3.6 g of the dried α-zirconium phosphate raw powder sample in 200 ml of deionized water, add 2 ml of methylamine solution with a concentration of 6 g / L dropwise, then ultrasonicate the formed gel for 0.5 hour, and place it at room temperature for 4 One day, the exfoliated α-zirconium phosphate colloid was obtained.

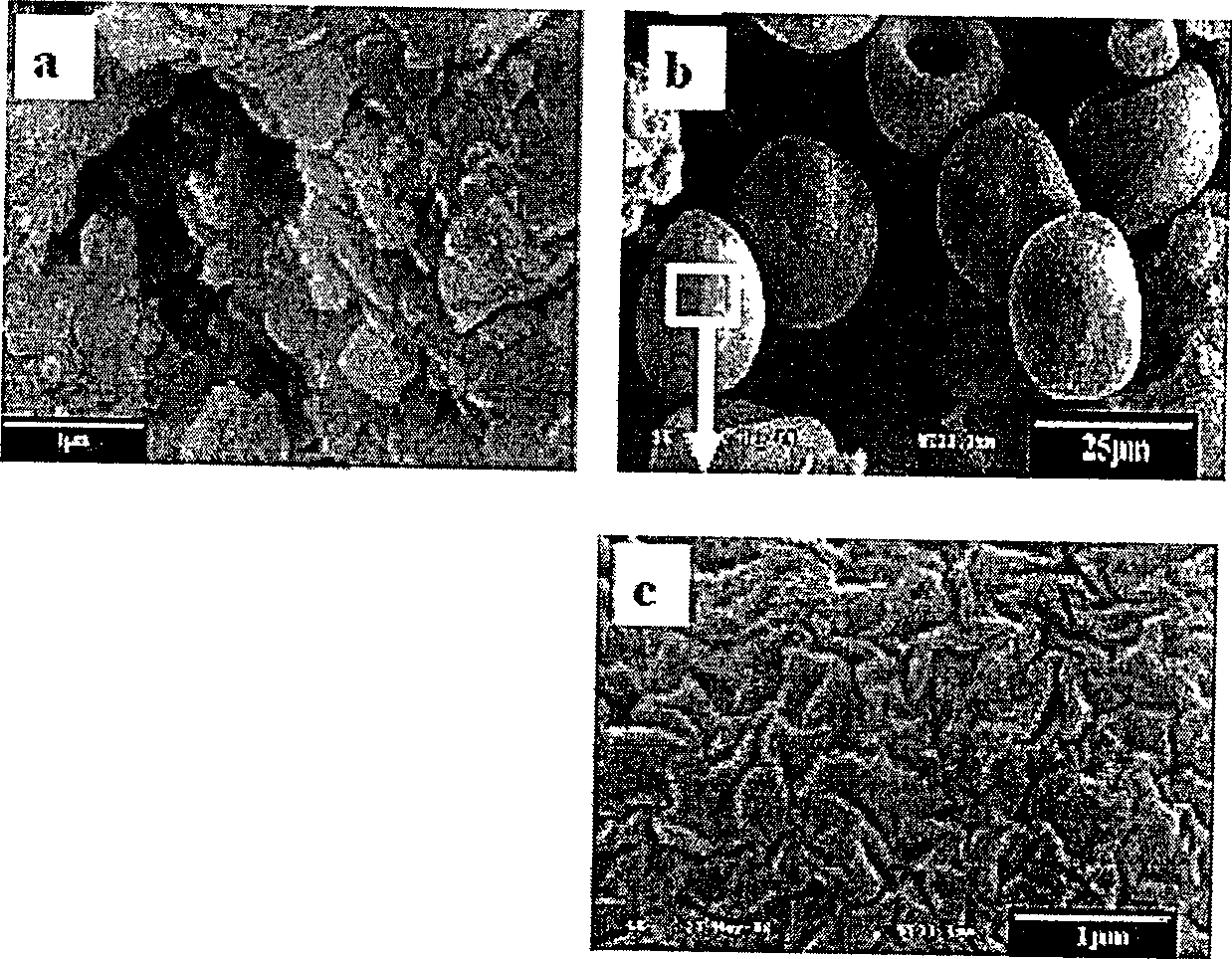

[0030] The obtained exfoliated zirconiu...

Embodiment 2

[0033] 5.5gZrOCl 2 ·8H 2 O is dissolved in 125ml concentration and is 2mol / L hydrochloric acid solution, the phosphoric acid 25ml that molar concentration is 4mol / L is mixed with the hydrochloric acid 25ml that molar concentration is 2mol / L to prepare mixed acid solution; ZrOCl 2 The salt solution is slowly added dropwise into the mixed acid solution to obtain zirconium phosphate gel; it is added to 50ml of phosphoric acid solution with a mass percentage of 85% and mixed evenly, and stirred and refluxed for 3 days at a temperature of 80°C to obtain α - Raw powder of zirconium phosphate.

[0034] Dissolve 2 g of the dried α-zirconium phosphate raw powder sample in 200 ml of deionized water, add 1 ml of ethylamine solution with a concentration of 5 g / L dropwise, then ultrasonicate the formed gel for 1 hour, and finally place it at room temperature for 4 One day, the exfoliated α-zirconium phosphate colloid was obtained.

[0035] The obtained exfoliated zirconium phosphate col...

Embodiment 3

[0037] 7gZrOCl 2 ·8H 2 O is dissolved in 125ml of hydrochloric acid solution with a concentration of 2.3mol / L, 35ml of phosphoric acid with a molar concentration of 4mol / L and 25ml of hydrochloric acid with a molar concentration of 2mol / L are mixed to prepare a mixed acid solution; ZrOCl 2 Slowly add the salt solution into the mixed acid solution to obtain a zirconium phosphate gel; add it to 100ml of 85% phosphoric acid solution by mass and mix evenly, and stir and reflux for 4 days at a temperature of 70°C to obtain α- Zirconium phosphate raw powder.

[0038] Dissolve 5 g of the dried α-zirconium phosphate raw powder sample in 300 ml of deionized water, add 3 ml of methylamine solution with a concentration of 5.5 g / L dropwise, then ultrasonicate the formed colloid for 1.5 hours, and finally place it at room temperature for 4 One day, the exfoliated α-zirconium phosphate colloid was obtained.

[0039] The obtained exfoliated zirconium phosphate colloid was formulated into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com