Method for detecting compaction degree of screen in flat plate reverse osmosis or nano-filtration membrane equipment

A flat plate reverse osmosis and detection method technology, applied in the detection field, can solve problems such as uneven distribution of fluid flow, accelerated membrane fouling, failure to retrieve the separation net, etc., and achieve the effect of simple and convenient detection procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

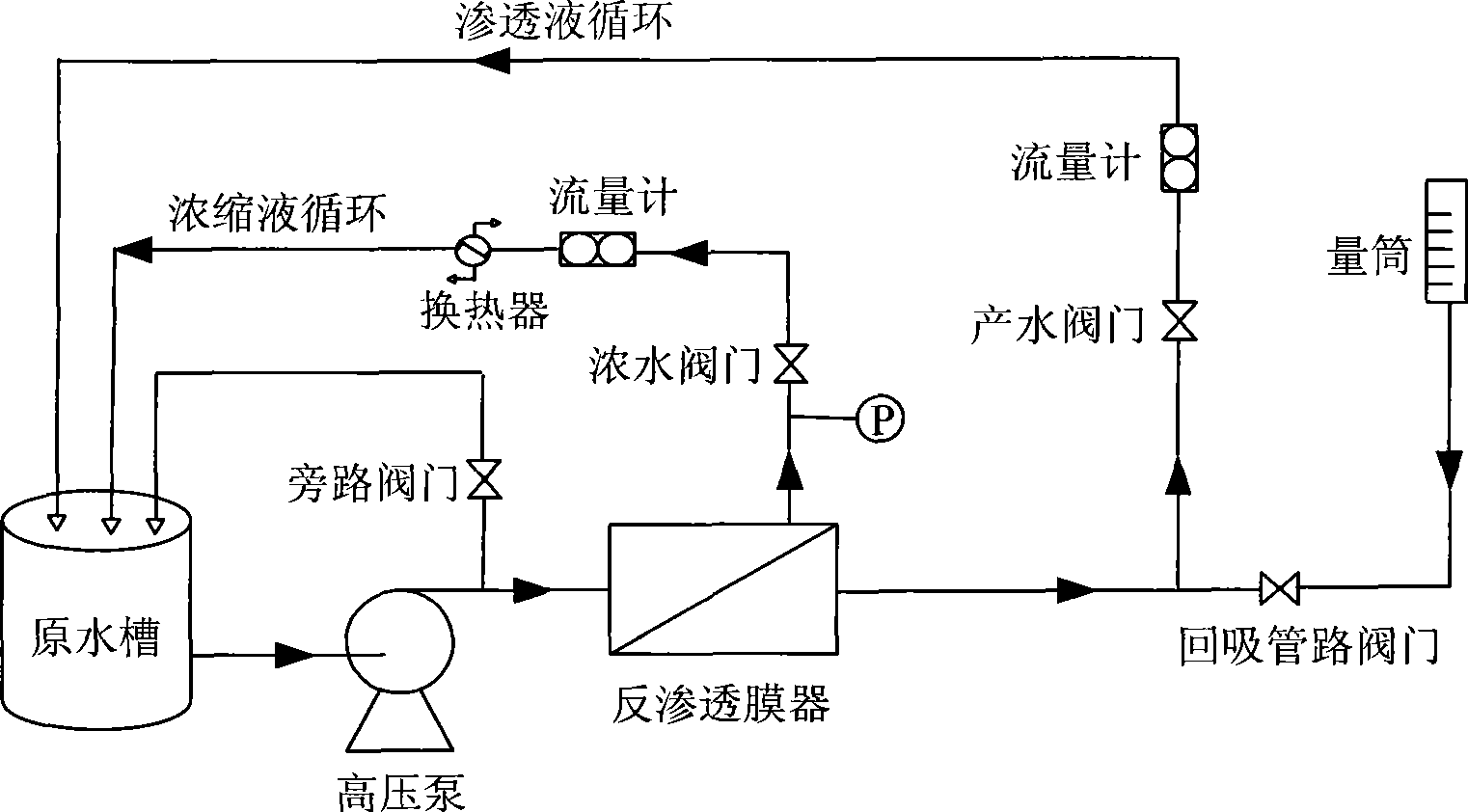

Method used

Image

Examples

Embodiment 1

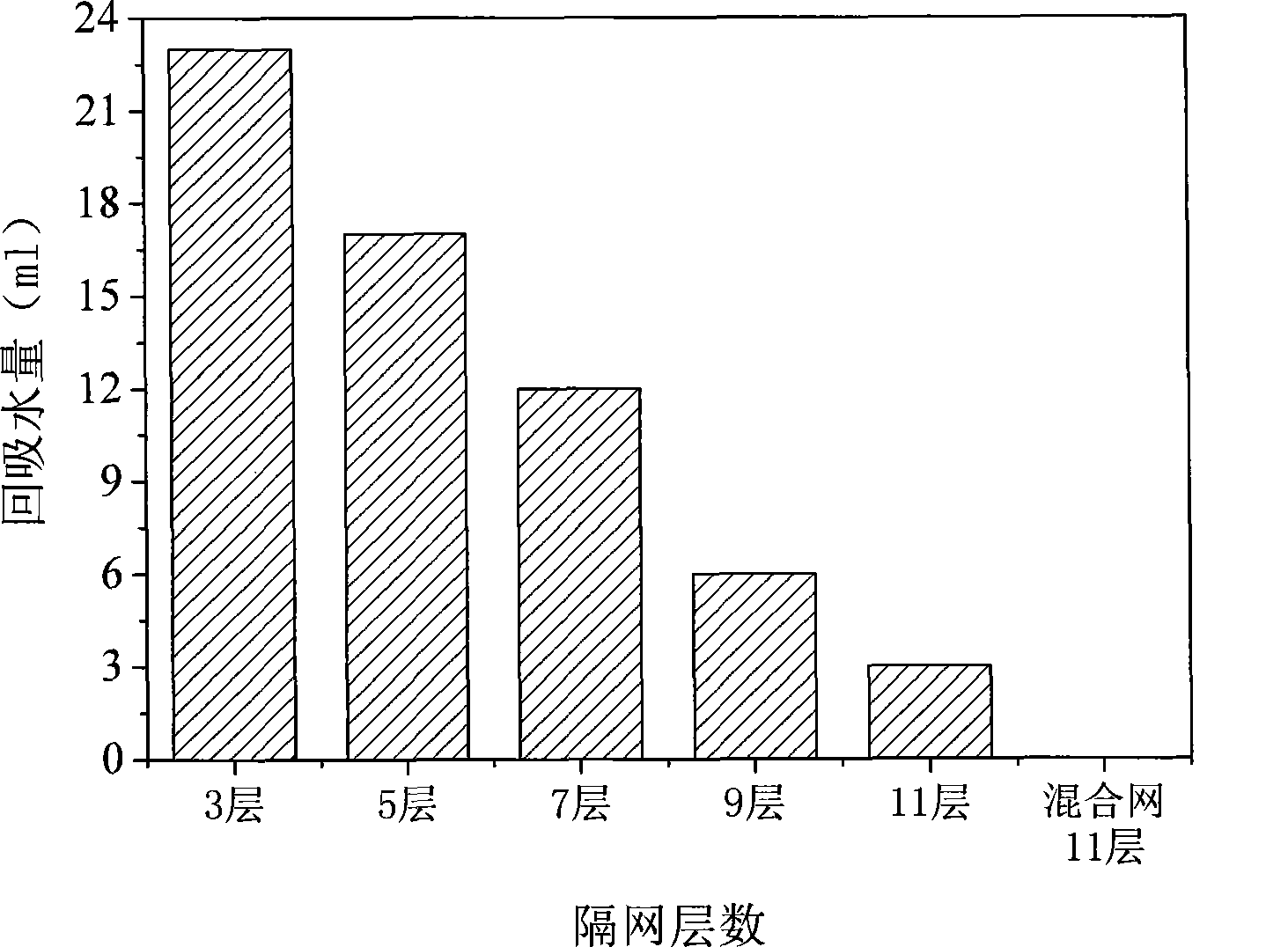

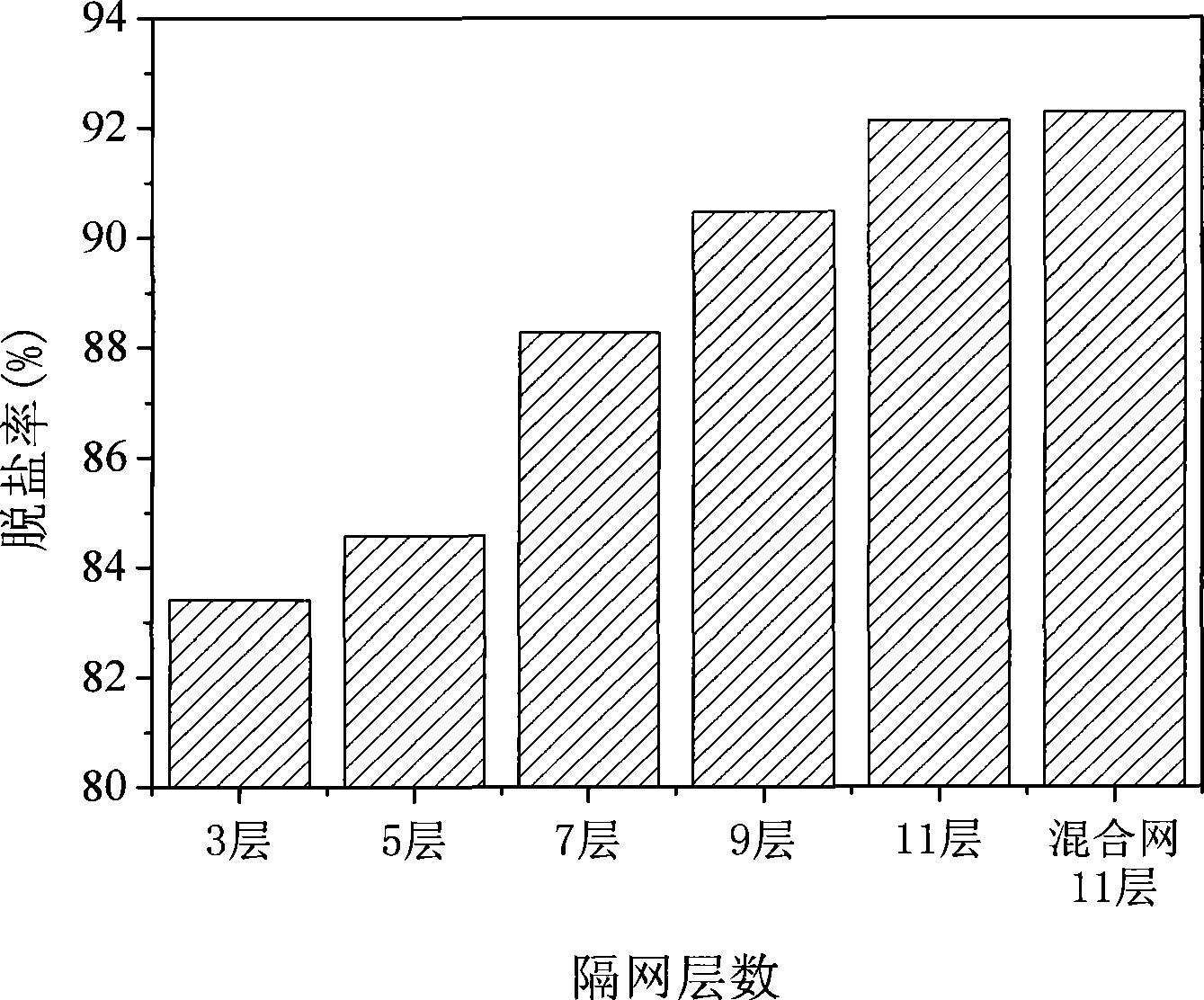

[0033] First, turn on the flat-panel reverse osmosis membrane equipment, and use one layer of water inlet screen, one layer of TW30-1812 flat reverse osmosis membrane and three layers of water production screen. Then the whole flat reverse osmosis membrane equipment is assembled. Subsequently, inject 20L of tap water filtered by activated carbon into the raw water tank, adjust the concentrated water valve in the reverse osmosis membrane system pipeline, the bypass valve and the cooling water flow in the heat exchanger, so that the system is at a temperature of 25 ° C and a pressure of Run for two hours under the conditions of 10bar and concentrate flow rate of 50L / h, record the conductance k of the influent water feed and product water conductance k perm , it can be concluded that the desalination rate of the reverse osmosis membrane is 83.4%. Then, reduce the system pressure to ≤2 bar, close the water production valve, open the suction line valve, turn off the diaphragm pum...

Embodiment 2

[0036] In this embodiment, the production water separation net is increased to five layers, and the entire flat reverse osmosis membrane equipment is fully assembled. Inject 20L of activated carbon-filtered tap water into the raw water tank, adjust the concentrated water valve, bypass valve and cooling water flow in the heat exchanger in the reverse osmosis membrane system pipeline, so that the system is at a temperature of 25°C and a pressure of 10bar. Run for two hours under the condition that the concentrate flow rate is 50L / h, record the conductance k of the influent water feed and product water conductance k perm , At this time, the desalination rate of the reverse osmosis membrane is 84.6%. Then, reduce the system pressure to ≤2 bar, close the water production valve, open the suction line valve, turn off the diaphragm pump, and record the liquid level drop of the measuring cylinder in the suction line within 20 seconds. At this time, the suction water volume is 17ml. T...

Embodiment 3

[0039]In the present embodiment, increase the water separation screen to seven layers. Inject 20L of activated carbon-filtered tap water into the raw water tank, adjust the concentrated water valve, bypass valve and cooling water flow in the heat exchanger in the reverse osmosis membrane system pipeline, so that the system is at a temperature of 25°C and a pressure of 10bar. Run for two hours under the condition that the concentrate flow rate is 50L / h, record the conductance k of the influent water feed and product water conductance k perm , At this time, the desalination rate of the reverse osmosis membrane is 88.3%. Then, reduce the system pressure to ≤2 bar, close the water production valve, open the suction line valve, turn off the diaphragm pump, and record the drop in the liquid level of the measuring cylinder in the suction line within 20 seconds. At this time, the suction water volume is 12ml. The result is as figure 2 and image 3 shown.

[0040] This example sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com