Perforated brick type filling support type reactor used in artificial liver

A reactor and perforated brick technology, applied in suction equipment, blood circulation treatment, etc., can solve the problems of easy generation of ineffective space, dead space, uneven distribution, etc., to reduce liquid flow resistance, strong comprehensive performance, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

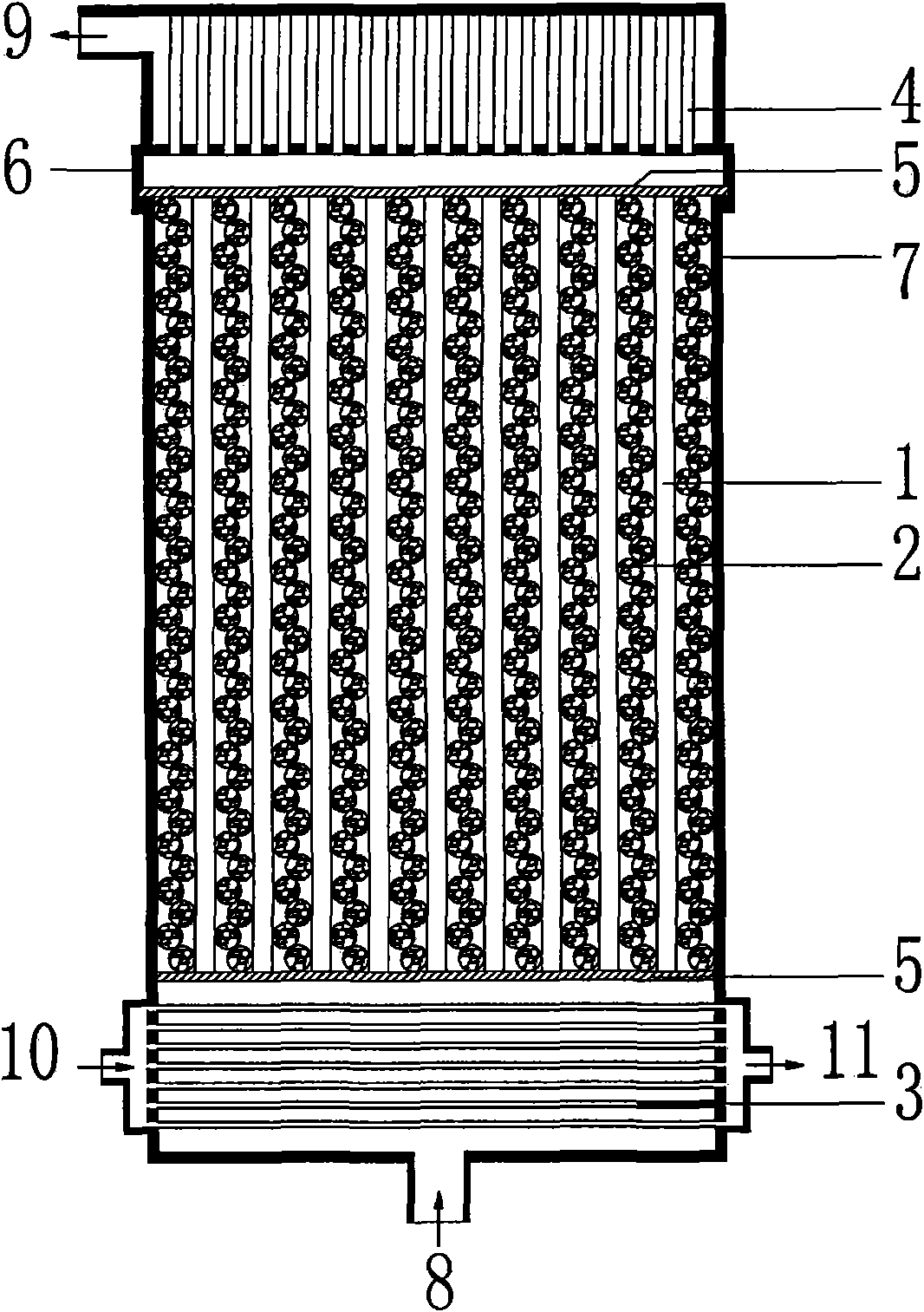

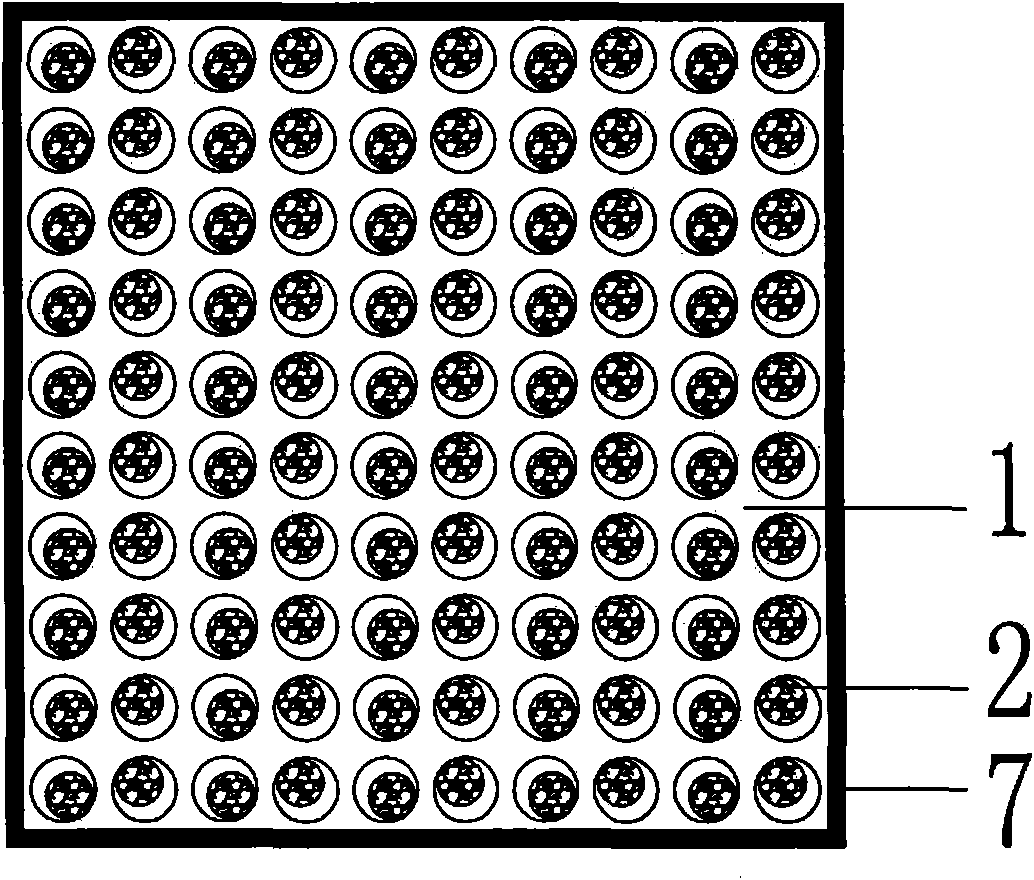

[0025] The artificial liver porous brick type filled bracket type reactor of the present embodiment comprises a cuboid transparent plexiglass reactor shell 7, and the reactor shell 7 is divided into three compartments by two dense grid-covered partition plates 5, from the bottom to the bottom. The above are the oxygenation cabin, the filling bracket cabin, and the immune barrier cabin. The oxygenation cabin and the filling bracket cabin are integrated, and the immune barrier cabin is an independent component, which is connected with the aforementioned whole through a sealed bayonet cover 6 .

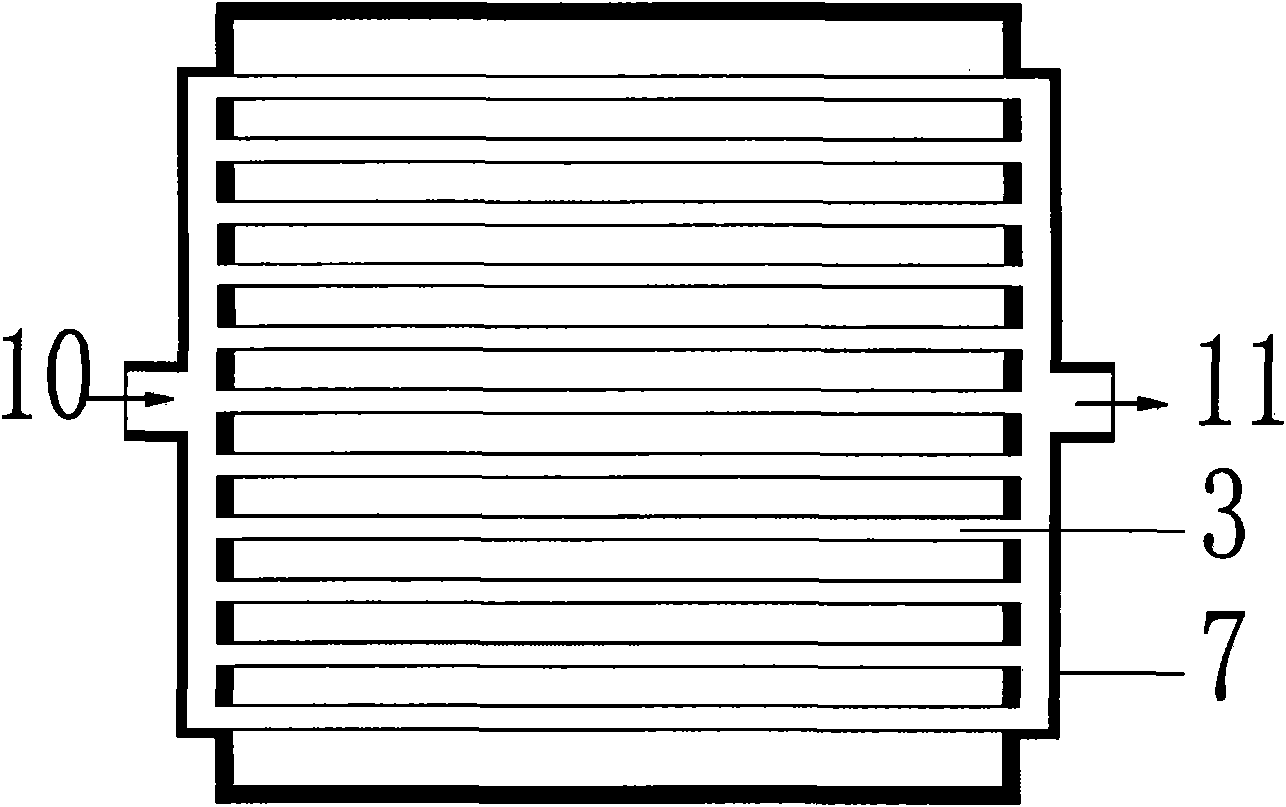

[0026] Air-permeable and impermeable hollow fibers 3 are arranged horizontally in the oxygenation chamber, and a liquid inlet 8 is arranged at the bottom of the chamber. The inside of the hollow fiber 3 is a gas channel, and the two ends are respectively connected with a gas inlet 10 and a gas outlet 11 . The hollow fiber 3 of the oxygenation chamber is a breathable and impermeable poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com