Conical barrate centrifugal extractor

An extractor and drum technology, which is applied in the field of extraction equipment, can solve the problems of poor self-priming of the cylindrical structure, and achieve the effects of avoiding wear pollution, large economic benefits, and ensuring synchronous rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

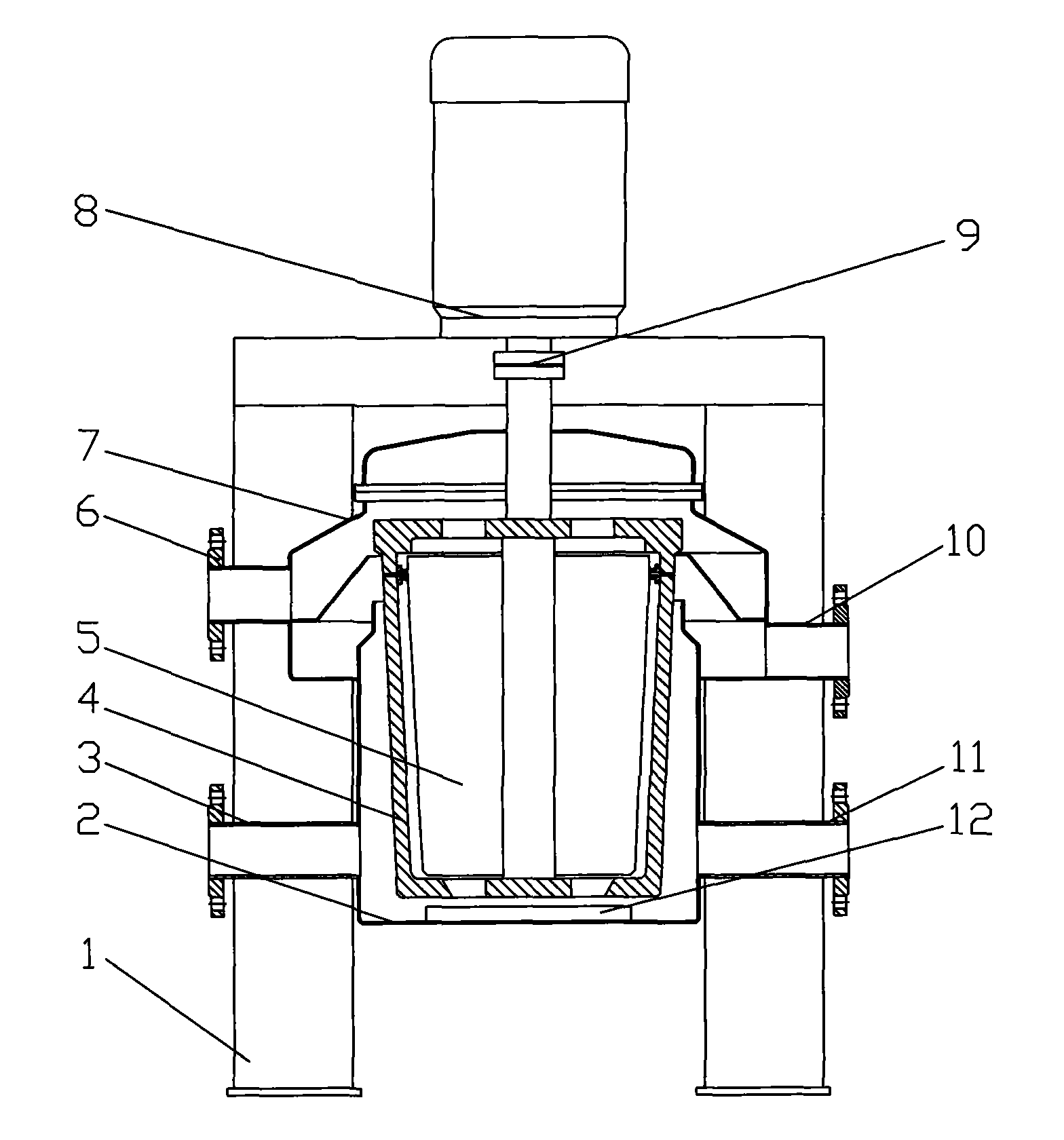

[0029] see figure 1 , a rotating drum 4 with blades 5 is arranged in the cylindrical housing 2, and each feed pipe and discharge pipe are respectively arranged on the side of the cylindrical housing 2, and the rotating drum 4 is set as a conical frustum body with a taper, and the conical frustum The body has a small lower bottom and a large upper bottom, and the size of the taper is properly set according to the density difference between the light and heavy phases. If the density difference is large, the taper can be appropriately smaller;

[0030] In order to ensure the synchronous rotation of the material and the drum, the blade 5 is set to have a taper that matches the drum 4, and the output shaft of the drive motor 8 is directly connected to the central shaft of the drum 4 with a coupling 9 to realize the drive motor. The direct drive form of the drum avoids problems such as wear and pollution caused by the belt drive.

[0031] The light and heavy phase materials are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com