Preparation of surface active agent of double long-chain alkyl amine oxide and applications thereof

A surfactant, double long-chain alkyl technology, applied in the field of colloid and interface chemistry, can solve the problem of inability to reduce the oil/water interfacial tension to ultra-low, and achieve the effect of improving oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of didecylmethyl amine oxide: react with didecylmethyl tertiary amine (product of Feixiang Chemical Co., Ltd.) and hydrogen peroxide in the presence of catalyst sodium edetate, the reaction medium is water, and the reaction temperature is 90 ℃, the molar ratio of hydrogen peroxide: tertiary amine is (1.1): 1, the catalyst consumption is 1% (relative to tertiary amine), the reaction time is 6 hours, and the conversion rate of tertiary amine is 80.5%. After the reaction, the aqueous phase is separated, and the upper layer is the product, which contains a small amount of unreacted tertiary amine.

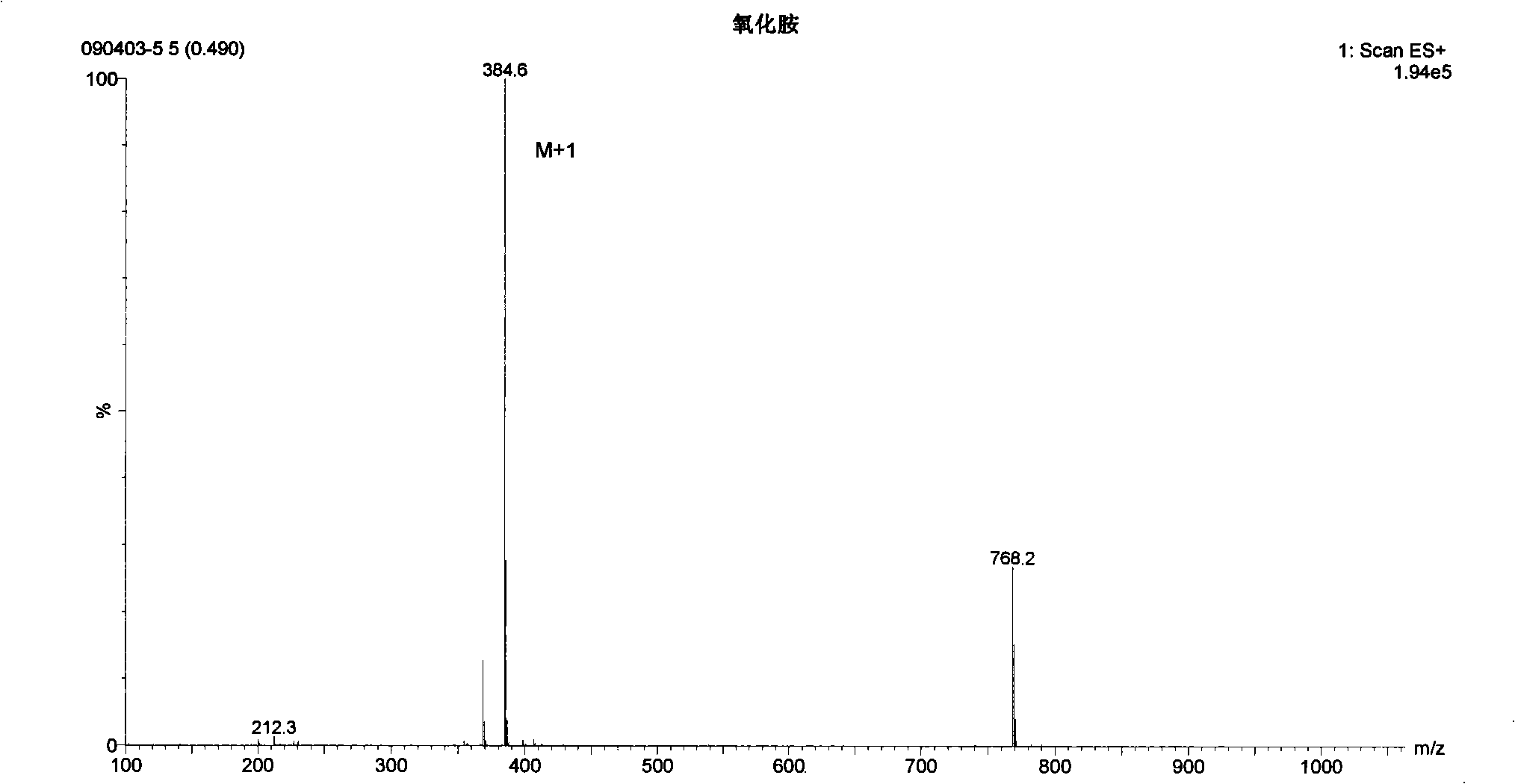

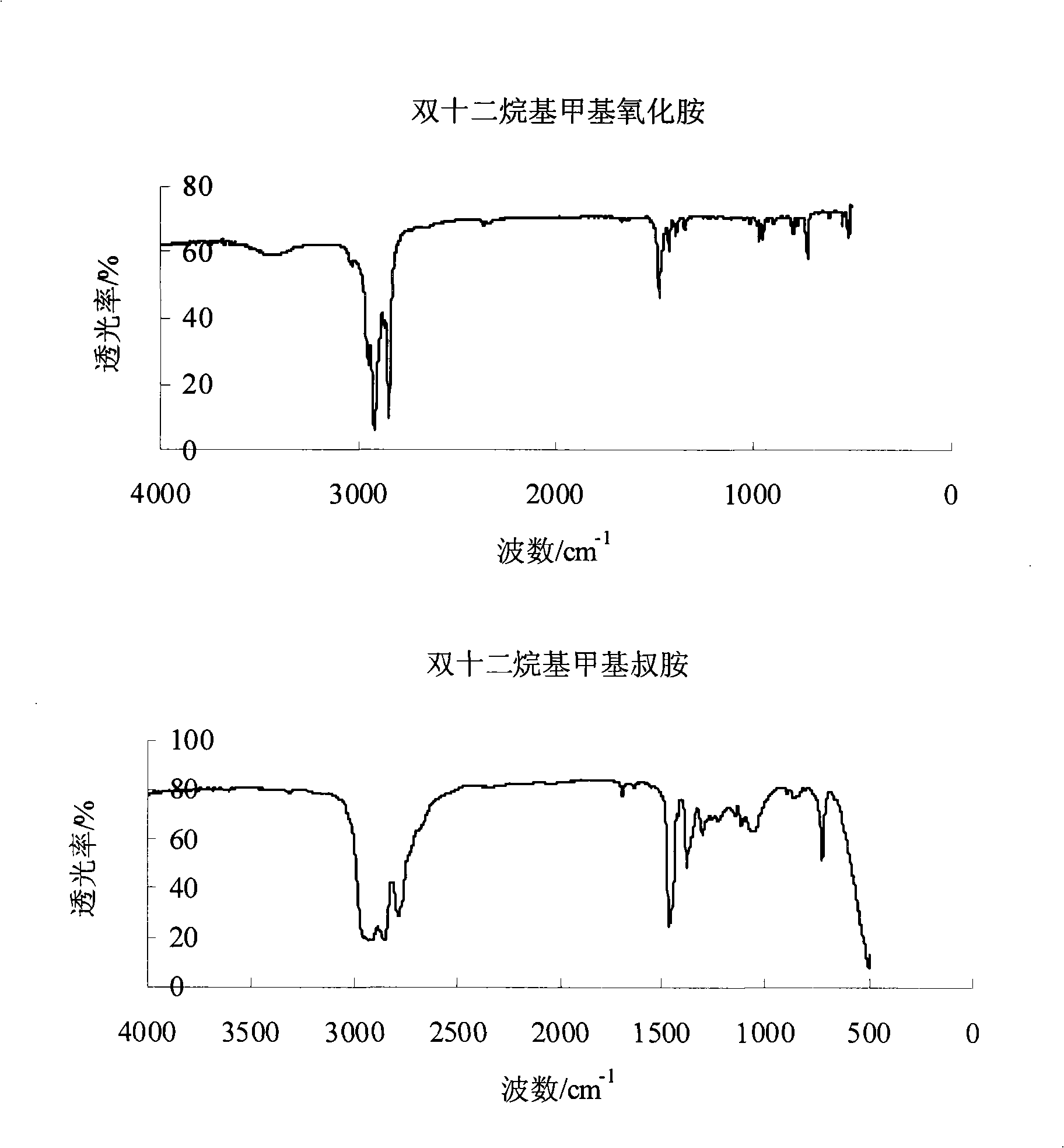

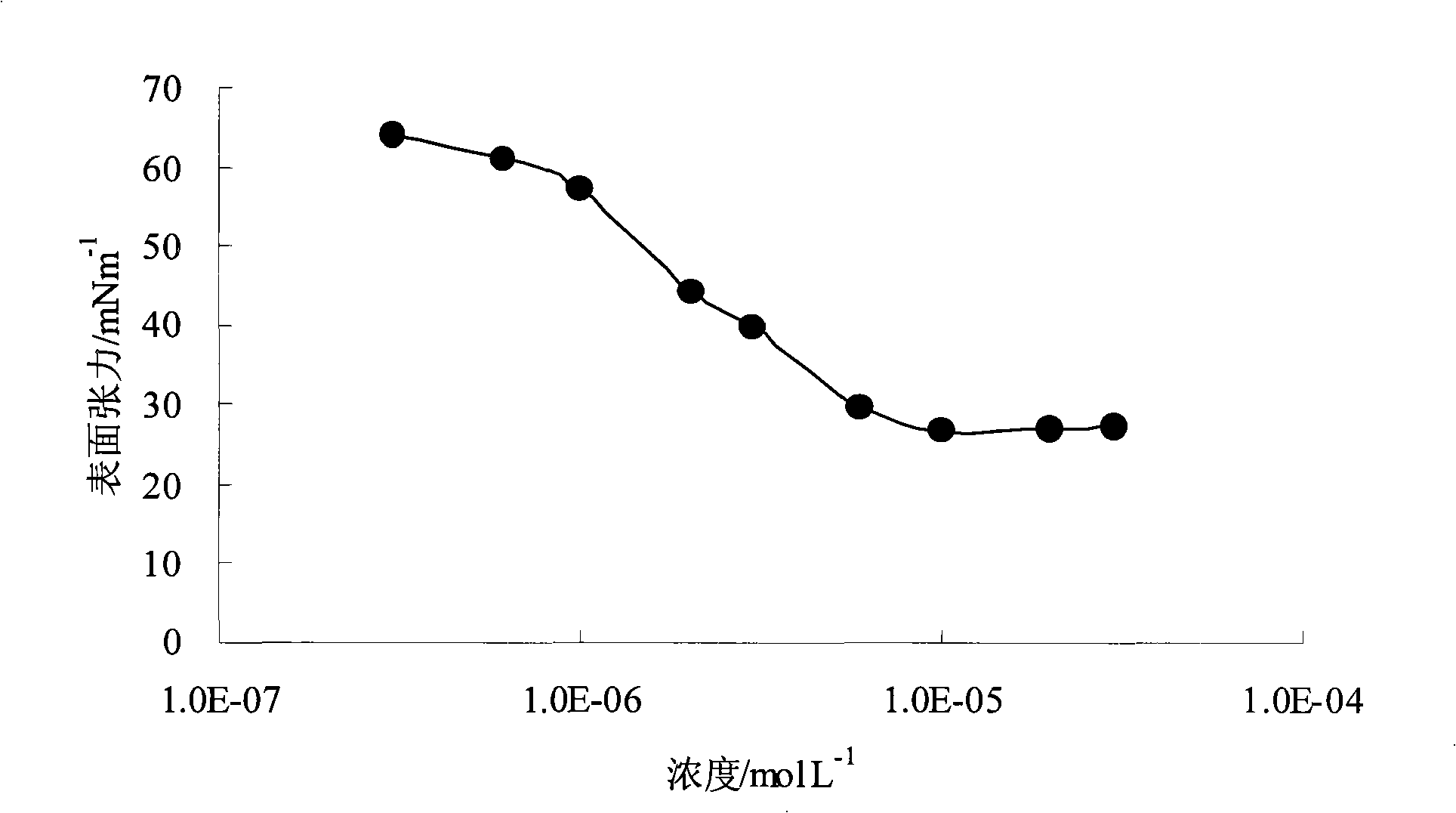

[0027] The preparation of didodecanylmethyl amine oxide: react with didodecanylmethyl tertiary amine (product of Feixiang Chemical Co., Ltd.) and hydrogen peroxide in the presence of catalyst sodium ethylenediaminetetraacetate, the reaction medium is water, and the reaction temperature is The temperature is 95° C., the molar ratio of hydrogen peroxide: tertiary a...

Embodiment 2

[0033] The prepared didecyl methyl amine oxide is compounded with a sulfonate type anionic surfactant, and the molar fraction of the didecyl methyl amine oxide is 0.5. The mixed surfactant was dissolved in Daqing formation water containing 1000ppm polyacrylamide, the total surfactant concentration (mass fraction) was 0.1% and 0.3%, respectively, and the interfacial tension with Daqing crude oil was measured at 45°C. Under the condition of no alkali and no addition of electrolyte, the equilibrium interfacial tension can be reduced to 10 -3 mN / m order of magnitude, such as Figure 4 shown.

Embodiment 3

[0035]The prepared didodecyl methyl amine oxide is compounded with a sulfonate type anionic surfactant, and the mole fraction of the didodecyl methyl amine oxide is 0.2. The mixed surfactant was dissolved in Daqing formation water containing 1000ppm polyacrylamide, the total surfactant mass fraction was 0.3%, and the interfacial tension with Daqing crude oil was measured at 45°C. Under the condition of no alkali and no addition of electrolyte, the equilibrium interfacial tension can be reduced to 10 -3 mN / m order of magnitude, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com