Compound oil displacement agent containing double-long-chain-alkyl sulphobetaine and application thereof

A long-chain alkyl sulfobeet and long-chain alkyl technology, which is applied in the field of oil displacement in oil extraction, can solve the problem of not being able to effectively reduce the interfacial tension of Daqing oilfield/formation water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

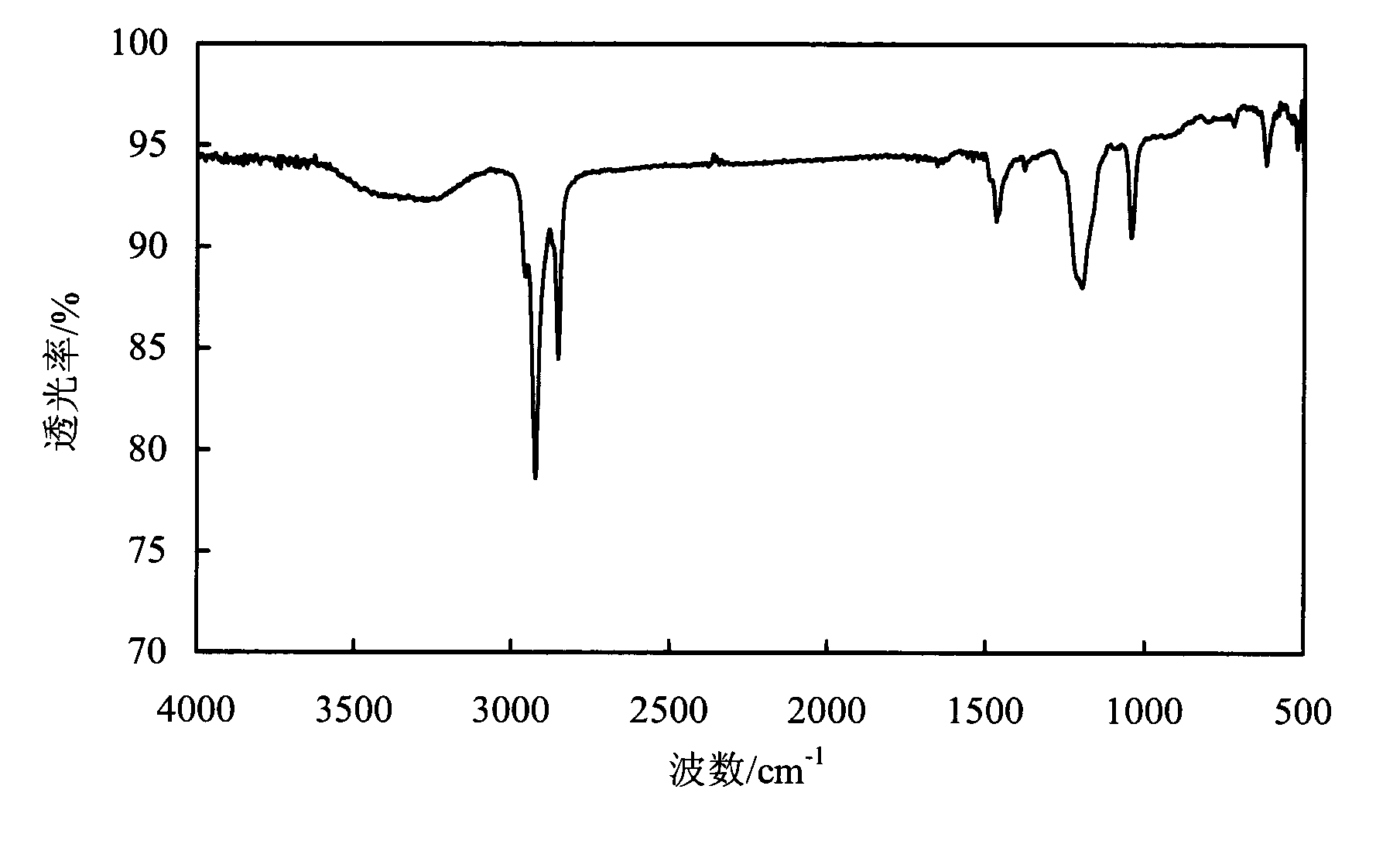

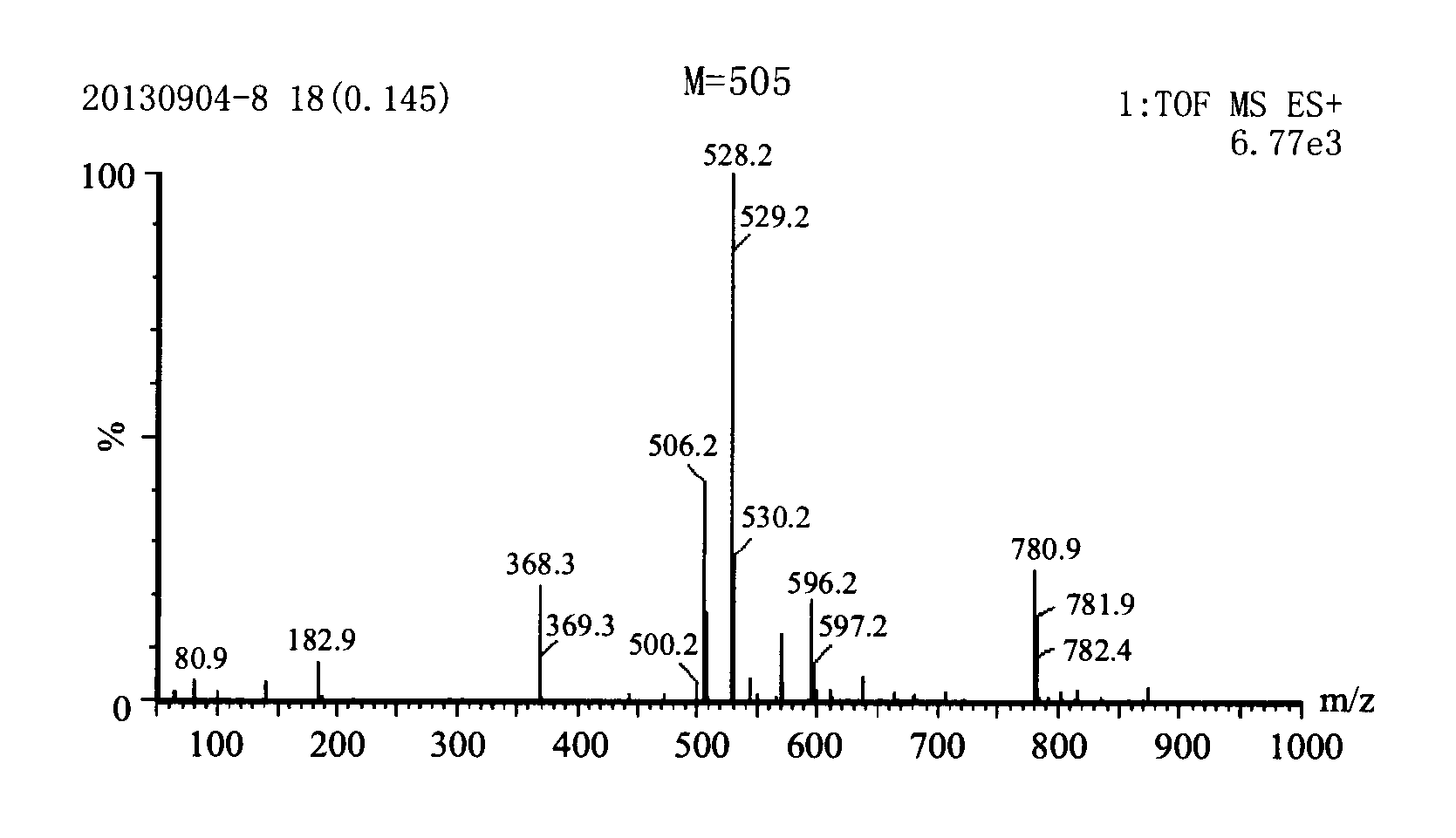

[0048] Embodiment 1 didodecylmethyl hydroxypropyl sultaine (diC 12 HSB) preparation

[0049] Use didodecanylmethyl tertiary amine (A) as raw material (Solvay Fine Chemical Co., Ltd.), react with 3-chloro-2-hydroxypropanesulfonate sodium (B) (Solvay Fine Chemical Co., Ltd.) , the molar ratio is A:B=1:1.1, and the reaction medium is a mixed solvent of isopropanol / water (volume ratio=6:1). A certain amount of sodium carbonate (B:Na 2 CO 3 =1:0.05) and 1.5% (based on tertiary amine) KI as catalyst. In a 500mL three-neck flask equipped with a stirring bar, a thermometer and a condenser tube, add 23.58g of sodium 3-chloro-2-hydroxypropanesulfonate, add 140mL of water / isopropanol mixed solution, and stir until completely dissolved. Then add 0.1mol (36.7g) diC 12 A and the required amount of sodium carbonate and potassium iodide. Heat up to 85°C, reflux for 48 hours, diC 12 A conversion rate can reach 90.2%. After the reaction was finished, the solvent was removed by rotary ev...

Embodiment 2

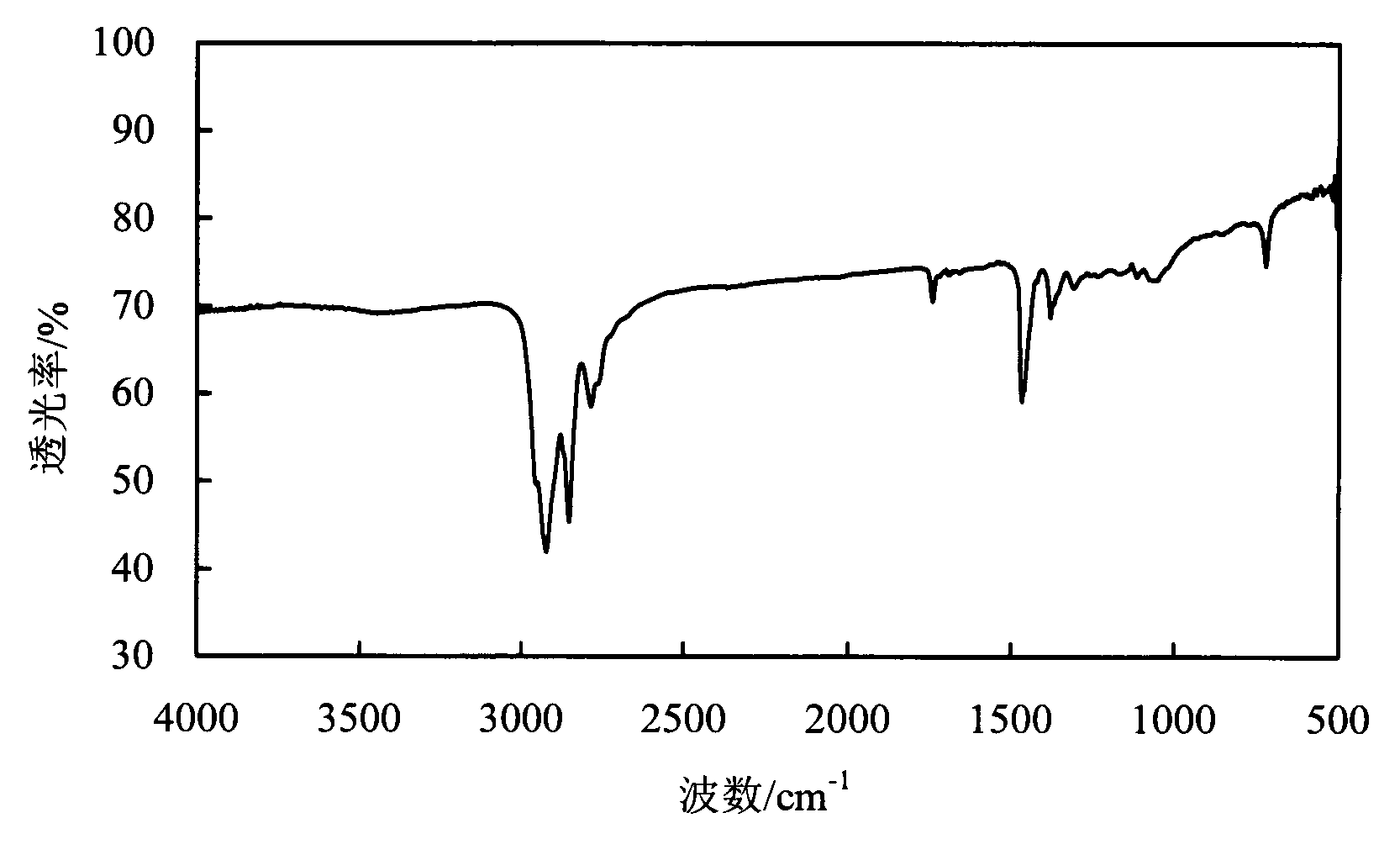

[0053] Embodiment 2 didodecyl methyl propyl sultaine (diC 12 SB) Preparation

[0054] Using didodecylmethyl tertiary amine (A) as raw material (Solvay Fine Chemicals Co., Ltd.), react with 1,3-propanesultone (D) (Jiangsu Mengde Electroplating Chemicals Co., Ltd.), mol The ratio is A:D=1:1.2, and the reaction medium is 1,2-dichloroethane. Add 0.1 mol of tertiary amine and 40 mL of 1,2-dichloroethane into a 250 mL three-necked flask equipped with a stirring bar, a thermometer and a condenser, start stirring, and raise the temperature to 50°C. A solution of 0.12 mol of 1,3-propanesultone dissolved in 40 mL of 1,2-dichloroethane was added dropwise into the reaction flask within half an hour. Heating the reactant to the reflux temperature of 80°C, reacting for 12 hours, adjusting the pH of the reaction mixture to weak alkaline with sodium hydroxide solution, diC 12 The conversion rate of A can reach 93%. After cooling, filter with suction, collect the product, add acetone and h...

Embodiment 3

[0058] The surface activity of embodiment 3 products

[0059] wxya 12 HSB and diC 12 SB has poor water solubility, but can be dissolved in toluene. At 25°C, by measuring the toluene / water interfacial tension ( Figure 5 ), get diC 12 The critical micelle concentration (cmc) of HSB is 1.8×10 -5 mol / L, saturated adsorption capacity Г ∞ 7.5×10 -10 mol / cm 2 , the corresponding molecular area is 0.22nm 2 / molecular. Similarly, to get diC 12 The cmc of SB is 4.5×10 -6 mol / L, saturated adsorption capacity Г ∞ 1.0×10 -9 mol / cm 2 , the corresponding molecular area is 0.17nm 2 / molecular. It can be seen that due to the lack of a hydroxyl group, diC 12 Hydrophilicity of SB compared to diC 12 The HSB is even lower, so the surfactant is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com