Method for preparing radix astragali homopolysaccharide

A technology of astragalus and polysaccharides, which is applied in the field of preparation of homopolysaccharides of astragalus, and achieves the effect of simple, fast and low-cost methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

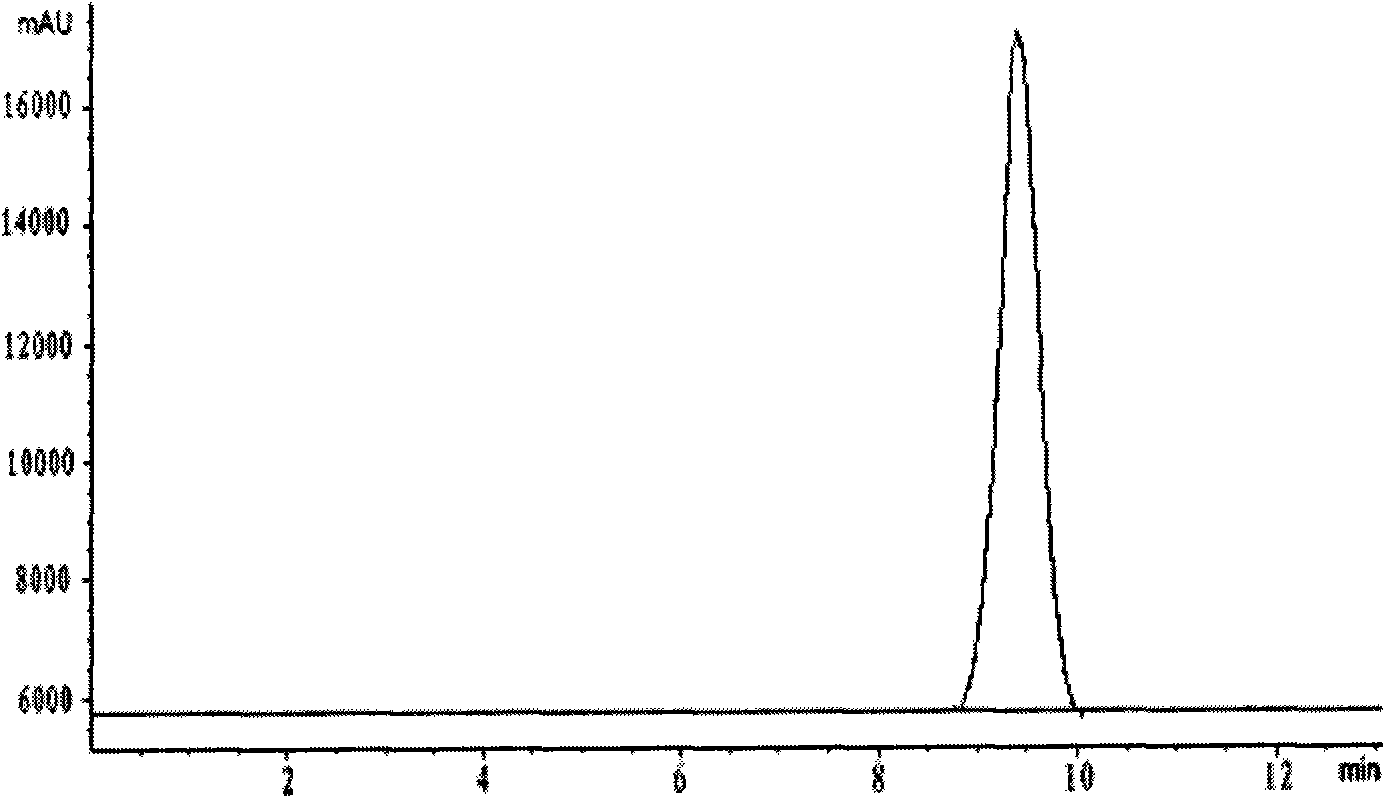

Image

Examples

Embodiment 1

[0024] Take 500g of astragalus crude powder, add 1500mL 95% ethanol (v / v) to reflux for defatting for 1.5h, filter, add 3000mL water to the residue and reflux extract three times, each time for 90min. The extract was filtered while hot, and the filtrates were combined and concentrated under reduced pressure to 1800 mL. Add 95% ethanol (v / v) to the concentrated solution at 4°C, stir, adjust the concentration of ethanol in the solution to 50% (v / v), and let stand overnight. Centrifuge to collect the precipitate, wash once with absolute ethanol, then wash once with acetone, repeat twice, and dry under vacuum at 60°C to obtain 25g of crude astragalus polysaccharide in the form of brown yellow powder, with an extraction yield of 5%.

[0025] Take 20g of crude polysaccharide to make 20g·L -1 Add 20g of pepsin to 1000mL aqueous solution, enzymatically hydrolyze at 37°C for 3h, boil for 10min to denature and precipitate excess protease, and remove by centrifugation. Add 250 mL of Se...

Embodiment 2

[0032] Take 500g of astragalus crude powder, add 1500mL of 95% ethanol (v / v) to reflux for defatting for 1.5h, filter, add 4500mL of water to the residue and reflux for extraction three times, each time for 90min. The extract was filtered while hot, and the filtrates were combined and concentrated under reduced pressure to 1800 mL. Add 95% ethanol (v / v) to the concentrated solution at 4°C, stir to adjust the alcohol concentration of the solution to 65% (v / v), and let stand overnight. Centrifuge to collect the precipitate, alternately wash twice with absolute ethanol and acetone, and vacuum-dry at 60° C. to obtain 50 g of crude astragalus polysaccharide in brown-yellow powder form, with an extraction yield of 10%.

[0033] Take 20g of crude polysaccharide to make 20g·L -1 Add 60g (m / m) of pepsin to 1000mL aqueous solution, enzymatically hydrolyze for 5h at 37°C, boil for 10min to denature and precipitate excess protease, and remove it by centrifugation. Add 200 mL of Sevage r...

Embodiment 3

[0037] Take 500g of Astragalus crude powder, add 1500mL 95% ethanol (v / v) to reflux for defatting for 1.5h, filter, add 6000mL water to the residue and reflux extract three times, each time for 90min. The extract was filtered while hot, and the filtrates were combined and concentrated under reduced pressure to 1800 mL. Add 95% ethanol (v / v) to the concentrated solution at 4°C, stir to adjust the alcohol concentration of the solution to 80%, and let stand overnight. Centrifuge to collect the precipitate, alternately wash twice with absolute ethanol and acetone, and vacuum-dry at 60° C. to obtain 75 g of crude astragalus polysaccharide in the form of brown yellow powder, with a yield of 15%.

[0038] Take 20g of crude polysaccharide to make 20g·L -1 Add 100g of pepsin to 1000mL aqueous solution, enzymatically hydrolyze at 37°C for 6h, boil for 10min to denature and precipitate excess protease, and remove by centrifugation. 150 mL of Sevage reagent (volume ratio of chloroform:n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com