Modified EVA microporous elastomer composite material and preparation method thereof

A technology of microcellular elastomers and composite materials, applied in the field of elastomer composite materials, can solve the problems of inability to meet the use in special fields, poor uniformity of material cells, low tensile strength of EVA microcellular elastomers, etc., and achieves easy operation. , the effect of improved tensile modulus and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

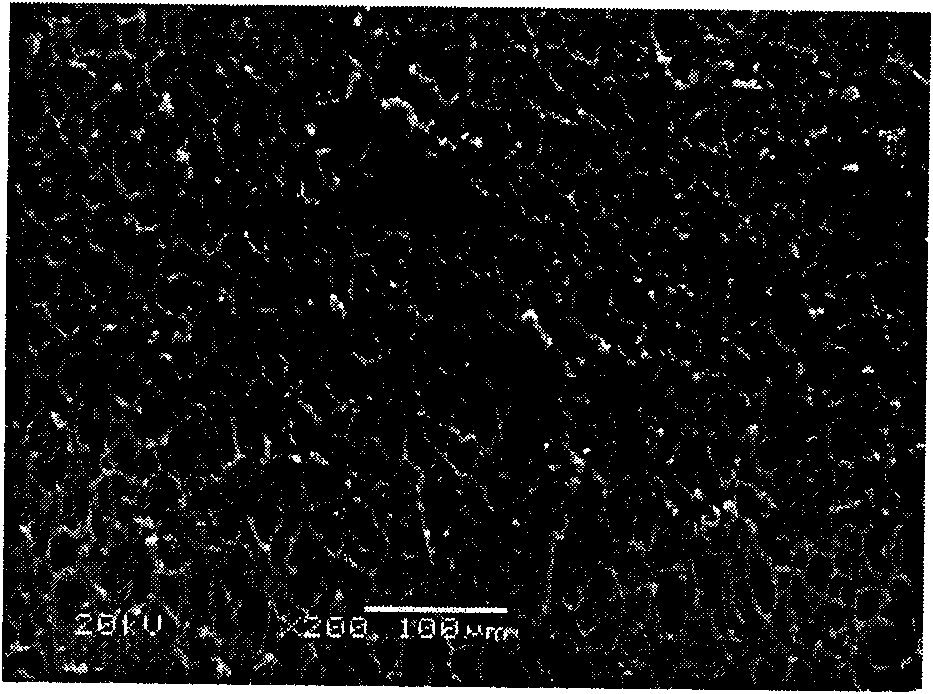

Image

Examples

Embodiment 1

[0041] The EVA of 200g is repeatedly kneaded for 5min through the triangular bag on the open double-roller kneader with a roll temperature of 90°C, and then the mass percentages are respectively 6%, 0.6%, 0.2%, 0.4% and 0.2%. Foaming agent, DCP, zinc oxide, zinc stearate and stearic acid are added in the EVA, and then continue to repeatedly knead for 25 minutes through the triangular bag on the open double-roller kneader;

[0042] Coat the inner wall of the metal mold with release agent evenly, and then heat the metal mold to 150°C; put the modified EVA material after kneading into the metal mold, seal the mold and put it in an oven, heat it to 150°C, and keep it warm After 20 minutes, demould after cooling to obtain EVA microporous elastomer material. The tensile strength of the prepared material was 1.97MPa, and the elongation at break was 84.39%.

Embodiment 2

[0044] EVA 200g, 20g of polyurethane and 15g of styrene-butadiene rubber were mixed repeatedly for 25 minutes on an open double-roll mixer with a roll temperature of 90°C, and then the mass percentages were respectively 6%, 0.6%, and 0.2%. , 0.4% and 0.2% de foaming agent, DCP, zinc oxide, zinc stearate and stearic acid are added in EVA, and then continue to repeatedly knead for 25 minutes through a triangular bag on an open double-roller kneader;

[0045] Coat the inner wall of the metal mold with release agent evenly, and then heat the metal mold to 150°C; put the modified EVA material after kneading into the metal mold, seal the mold and put it in an oven, heat it to 150°C, and keep it warm After 20 minutes, demould after cooling to obtain EVA microporous elastomer material. The tensile strength of the prepared material was 2.23MPa, and the elongation at break was 104.23%.

Embodiment 3

[0047] The polyurethane of EVA200g, 20g and the styrene-butadiene rubber of 15g are mixed repeatedly 25min through the triangular bag on the open double-roller kneading machine that roll temperature is 90 ℃, and then the organic montmorillonite that mass fraction is 1% is added to the modification In the EVA material, continue to repeatedly knead for 25 minutes through the triangular bag on the open double-roller kneader;

[0048] The mass percentage content is respectively 6%, 0.6%, 0.2%, 0.4% and 0.2% de foaming agent, DCP, zinc oxide, zinc stearate and stearic acid are added in the modified EVA material, then continue to open Repeatedly kneading for 25min through the triangular bag on the double-roller kneader;

[0049] Coat the inner wall of the metal mold with release agent evenly, and then heat the metal mold to 150°C; put the modified EVA material after kneading into the metal mold, seal the mold and put it in an oven, heat it to 150°C, and keep it warm After cooling f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com