Anti-fogging surface treating agent and anti-fogging resin sheet

A surface treatment agent and anti-fog technology, which is applied in the field of containers endowed with anti-fog properties, can solve the problems of difficulty in obtaining high anti-fog properties and reduced anti-fog properties, and achieve high anti-fog properties and maintain anti-fog properties. Fog, high anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

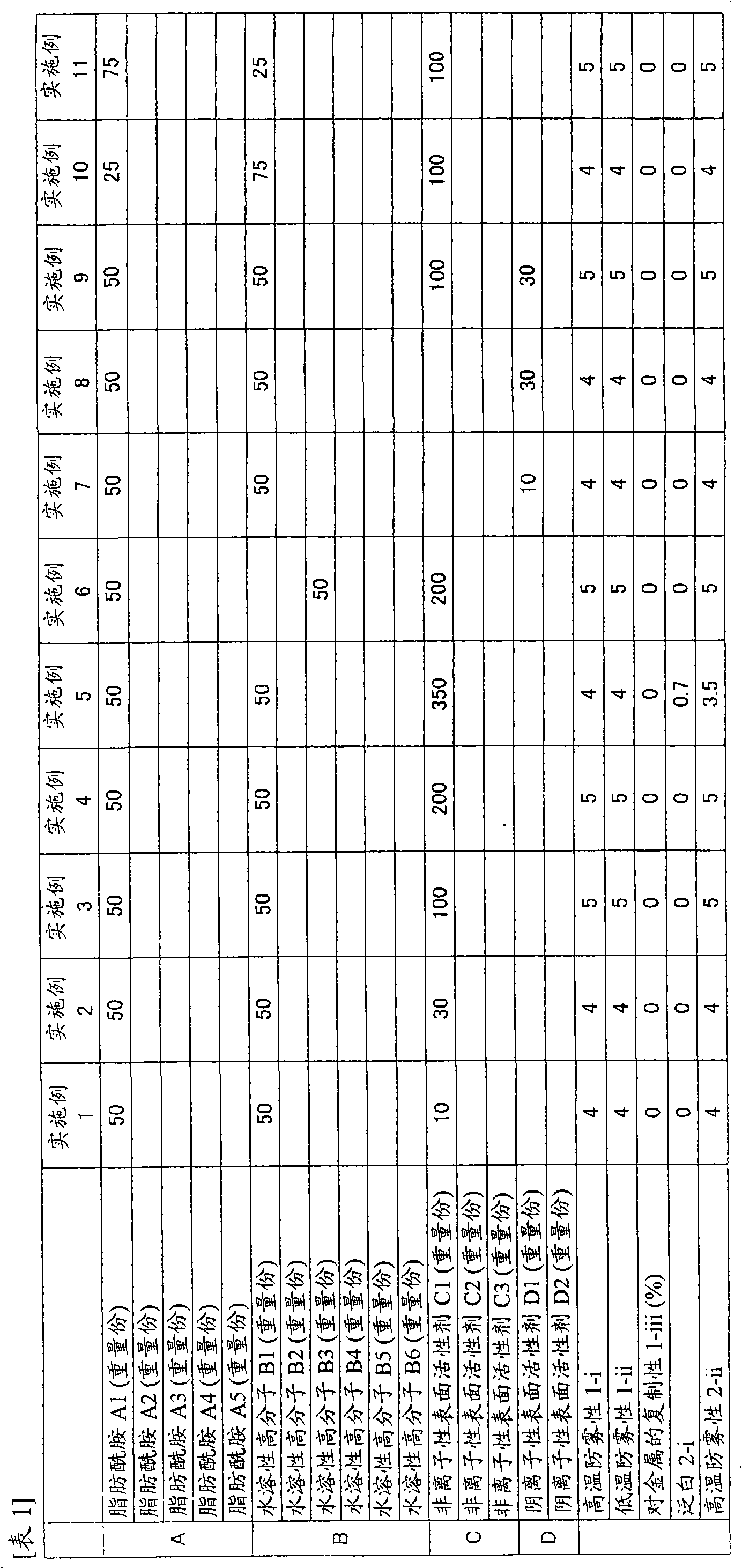

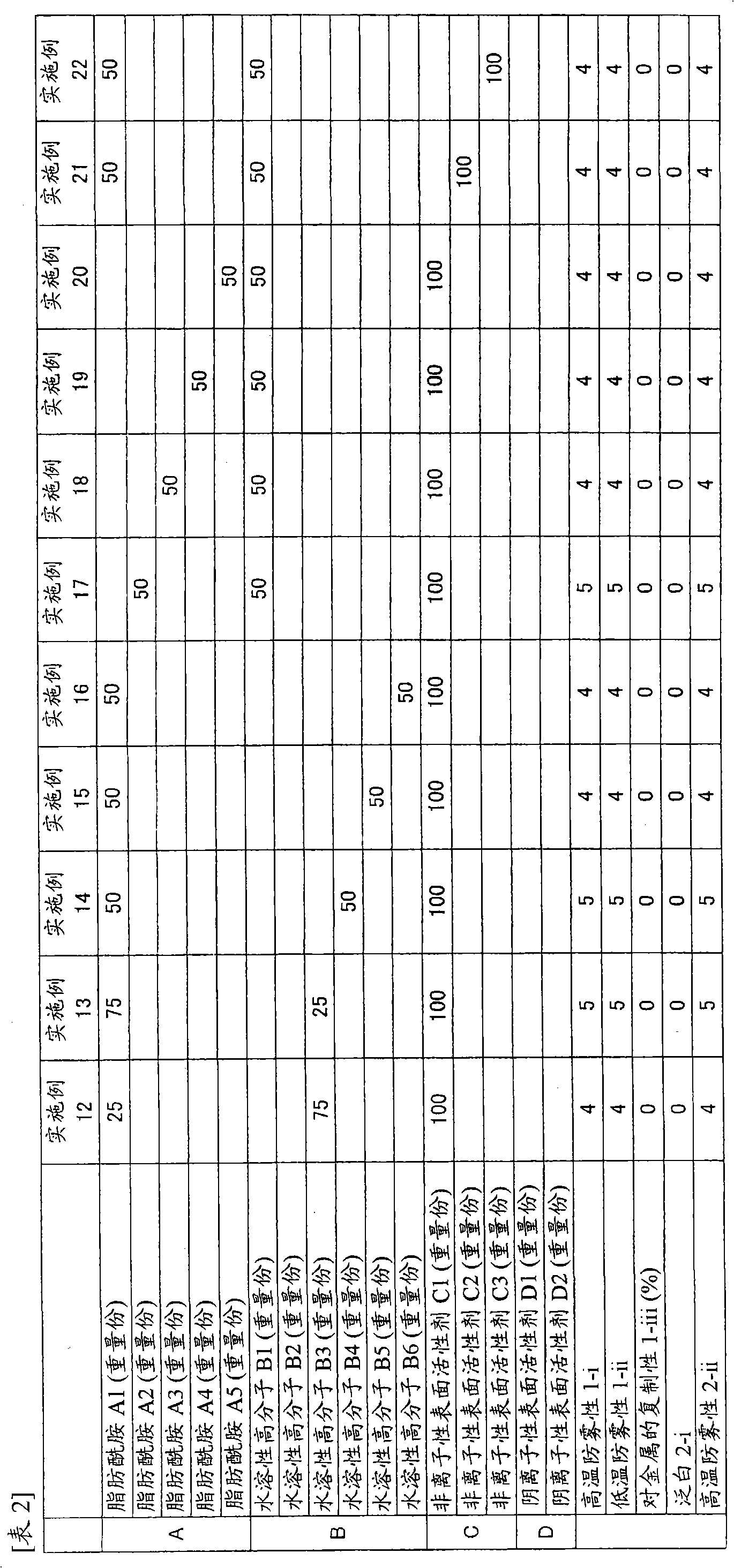

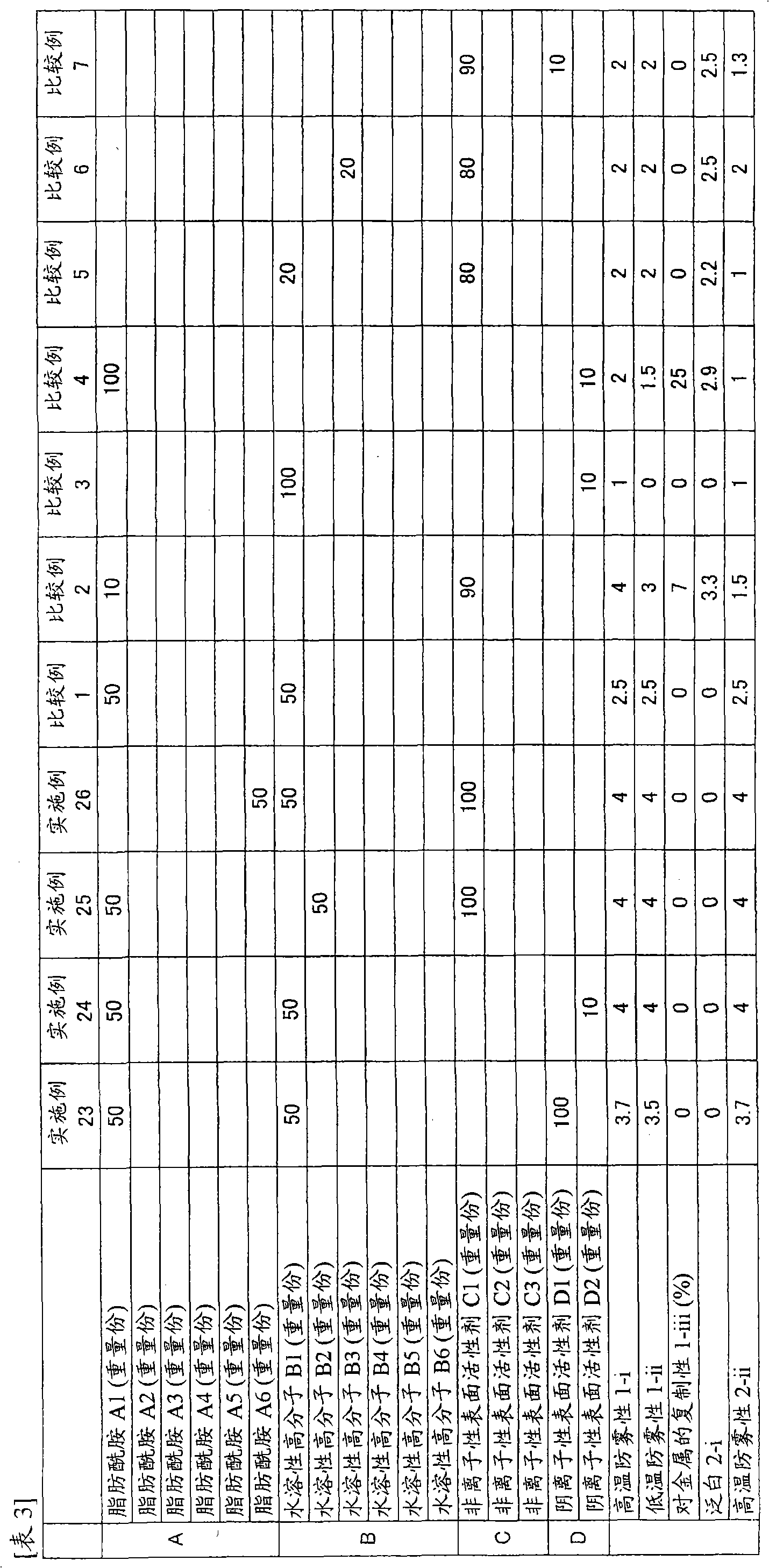

Embodiment 1~26 and comparative example 1~7

[0147] Prepare a water-based surface treatment agent (anti-fog treatment agent) so that the solid content ratio of each component (the weight ratio of each component after drying) satisfies the ratio (parts by weight) shown in the table. Here, the concentration of the treatment agent differs depending on the evaluation item, and the concentration of the treatment agent indicates the concentration (% by weight) of the solid content. Next, on the corona discharge-treated surface of a biaxially stretched polystyrene sheet having a sheet thickness of 0.25 mm, a specified amount of a water-based surface treatment agent (anti-fog treatment agent) corresponding to the following evaluation characteristic items was applied, and used Drying was performed at 80°C for 2 minutes with a hot air dryer to form an anti-fog layer.

[0148] The properties (initial properties) of the obtained anti-fog resin sheet and the properties of the sheet obtained by laminating and pressing the anti-fog res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com