Dual-layer steel truss-Ferris wheel combined bridge

A ferris wheel and steel truss technology, which is applied in the field of double-layer steel truss-ferris wheel combined bridges, can solve the problems of unfavorable lateral stiffness, processing and assembly risks of ferris wheel bridges, and increased bridge deck burden, so as to reduce processing and assembly risk, eliminate the unclear structural stress, and reduce the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Main parts and details of the present invention:

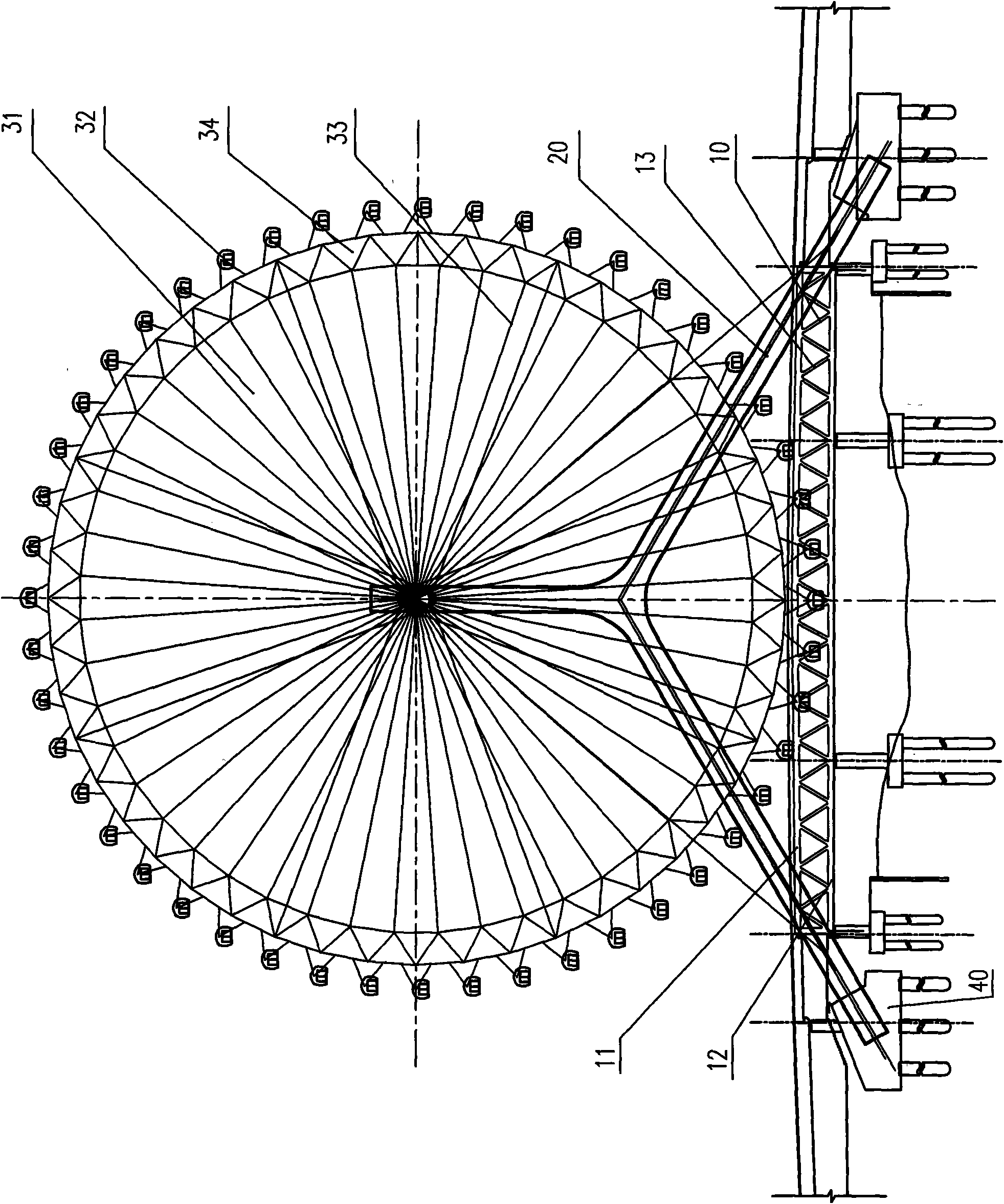

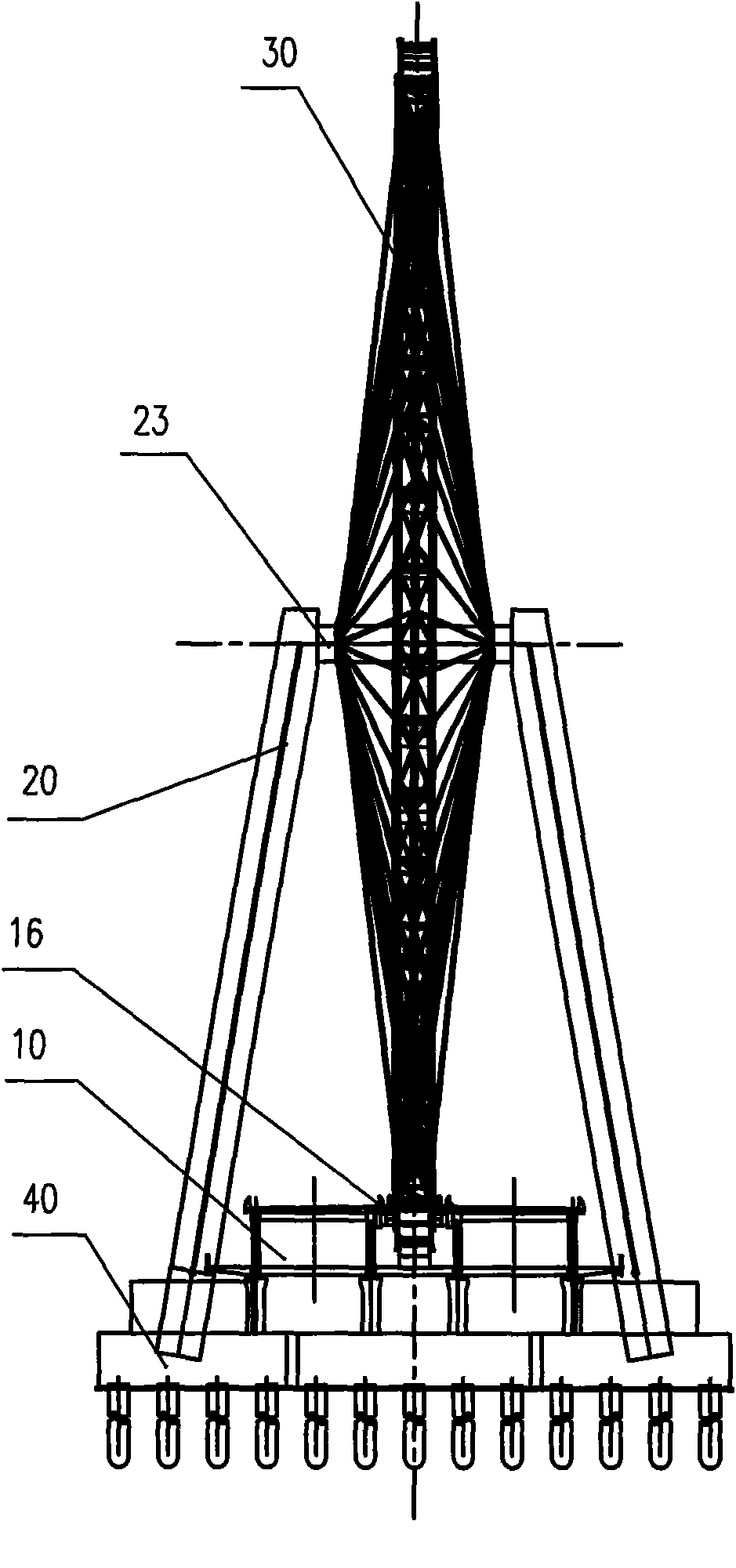

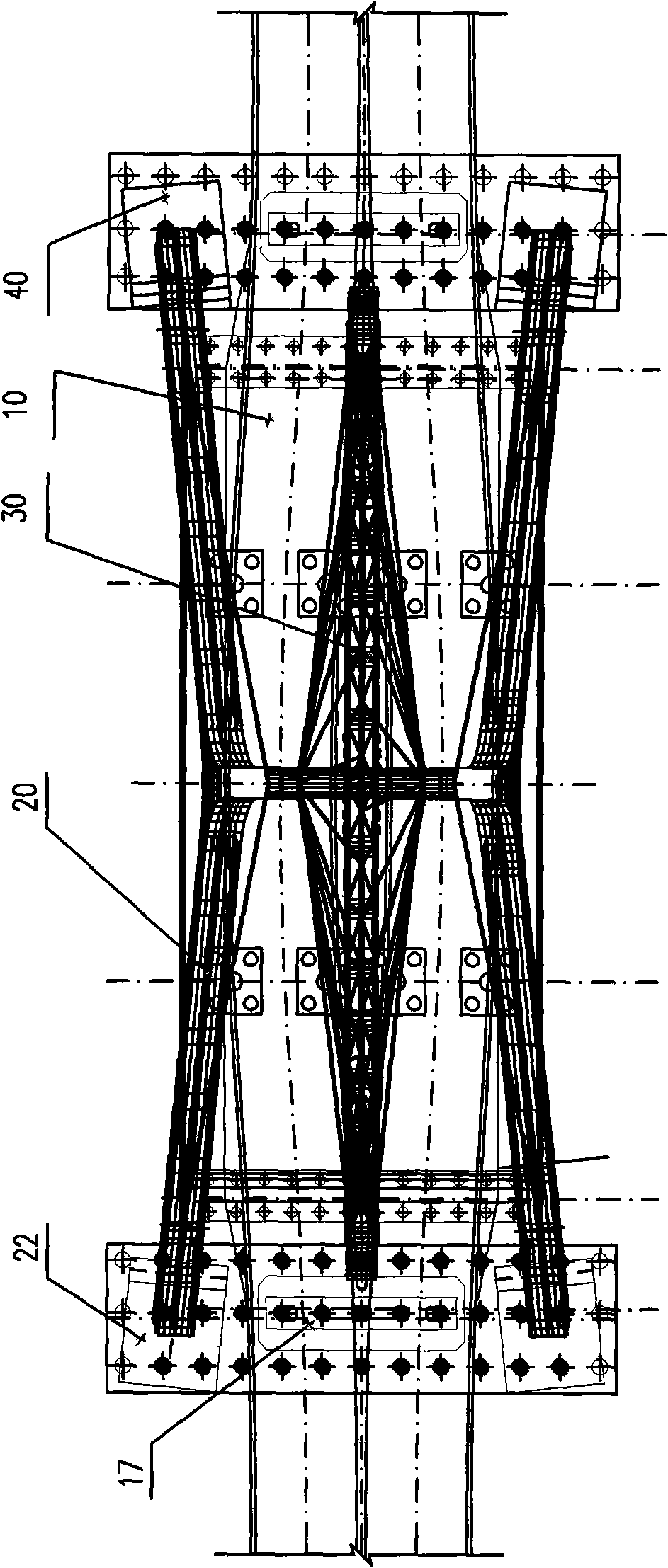

[0019] 10. Main bridge, 20. Supporting tower, 30. Ferris wheel, 40. Composite wheel bridge foundation, 11. Upper bridge, 12. Lower bridge, 13. Main truss, 16. Opening, 17. First foundation, 22 .Second foundation, 23. Support tower beam (central shaft), 31. Wheel disc, 32. Car, 33. Cable, 34. Tire.

[0020] Such as figure 1 , figure 2 and image 3 Shown, the technical scheme that the present invention's double-deck steel truss-ferris wheel combined bridge is realized is: comprise main bridge 10, support tower 20, ferris wheel 30 and composite type wheel bridge foundation 40; Described main bridge 10 adopts double The structural type of the steel truss girder of the first floor, the upper bridge 11 of the main bridge adopts a steel fiber concrete deck, the lower bridge 12 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com