Organic fibre brake pad with satisfactory radiating effect

An organic fiber and heat dissipation technology, which is applied in the field of automobile brake pads, can solve the problems of large damage to brake drums or brake discs, poor heat dissipation of organic brake pads, and easy corrosion of metal brake pads, etc., and achieve high-temperature thermal fading resistance Good, sensitive braking, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: cashew nut oil friction powder 9%, tire powder (60-80 order) 5%, chromite powder 4%, calcined petroleum coke 4%, flake graphite 3%, flake aluminum powder 5% by weight percentage , silicate fiber 4%, antimony sulfide 7%, brass fiber 7%, spray aluminum silicate fiber 3%, vermiculite powder (20-40 mesh) 9%, silicone modified phenolic resin 15%, recrystallization 10% of stone powder (600 mesh), 1% of polyacrylonitrile fiber, 3% of wood pulp fiber, 4% of viscose fiber, and 4% of bamboo carbon fiber are put into the high-speed disperser, stirred into powder, taken out, and put into the forming mold It is internally pressed and formed, then compounded with a steel back and placed in a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa, and kept for 15 minutes, then the brake pads are taken out, and the burrs are removed to become a finished product.

[0018] The silicate fibers used in this embodiment contain components and their proportions a...

Embodiment 2

[0019] Embodiment 2: cashew nut oil friction powder 5%, tire powder (60-80 order) 6.5%, chromite powder 8%, calcined petroleum coke 7%, flake graphite 7%, flake aluminum powder 6% by weight percentage , silicate fiber 7%, antimony sulfide 4%, brass fiber 4%, spray aluminum silicate fiber 5%, vermiculite powder (20-40 mesh) 12%, silicone modified phenolic resin 10%, recrystallization 7% of stone powder (600 mesh), 0.5% of polyacrylonitrile fiber, 6% of wood pulp fiber, 3% of viscose fiber, and 3% of bamboo carbon fiber are put into the high-speed disperser, stirred into powder, taken out, and put into the forming mold It is internally pressed and formed, then compounded with a steel back and placed in a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa, and kept for 15 minutes, then the brake pads are taken out, and the burrs are removed to become a finished product.

[0020] The silicate fibers used in this embodiment contain components and their proportio...

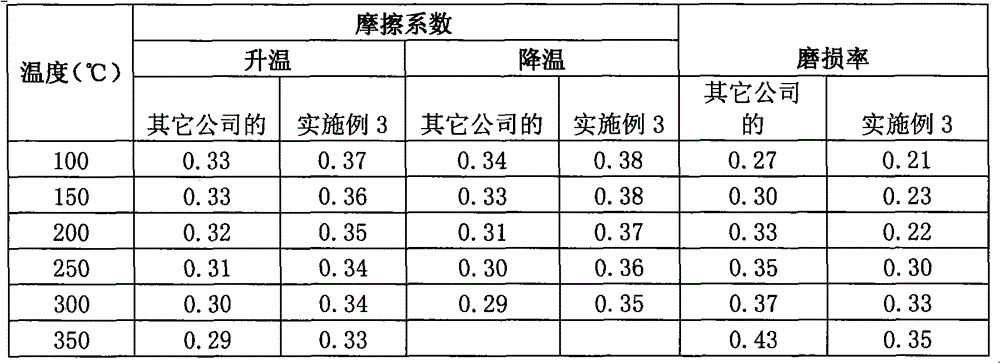

Embodiment 3

[0021] Embodiment 3: cashew nut oil friction powder 7%, tire powder (60-80 order) 5%, chromite powder 5%, calcined petroleum coke 5%, flake graphite 5%, flake aluminum powder 7% by weight percentage , silicate fiber 6%, antimony sulfide 6%, brass fiber 6%, spray aluminum silicate fiber 4%, vermiculite powder (20-40 mesh) 9%, silicone modified phenolic resin 11%, recrystallization Put stone powder (600 mesh) 9%, polyacrylonitrile fiber 0.8%, wood pulp fiber 4.2%, viscose fiber 4%, bamboo carbon fiber 6% into the high-speed disperser, stir it into powder, take it out, and put it into the forming mold It is internally pressed and formed, then compounded with a steel back and placed in a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa, and kept for 15 minutes, then the brake pads are taken out, and the burrs are removed to become a finished product.

[0022] The silicate fibers used in this embodiment contain components and their proportions are: SiO 2 53%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com