Metal phosphide used as lithium ion secondary battery cathode material and preparation method thereof

A metal phosphide and secondary battery technology, applied in phosphide, electrode manufacturing, battery electrodes, etc., can solve problems such as difficulty in finding suitable positive electrode materials, no significant improvement in cycle performance, and increased difficulty in lithium-poor positive electrode materials. It is conducive to large-scale promotion and application, has great practical significance in production, and is easy to control the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

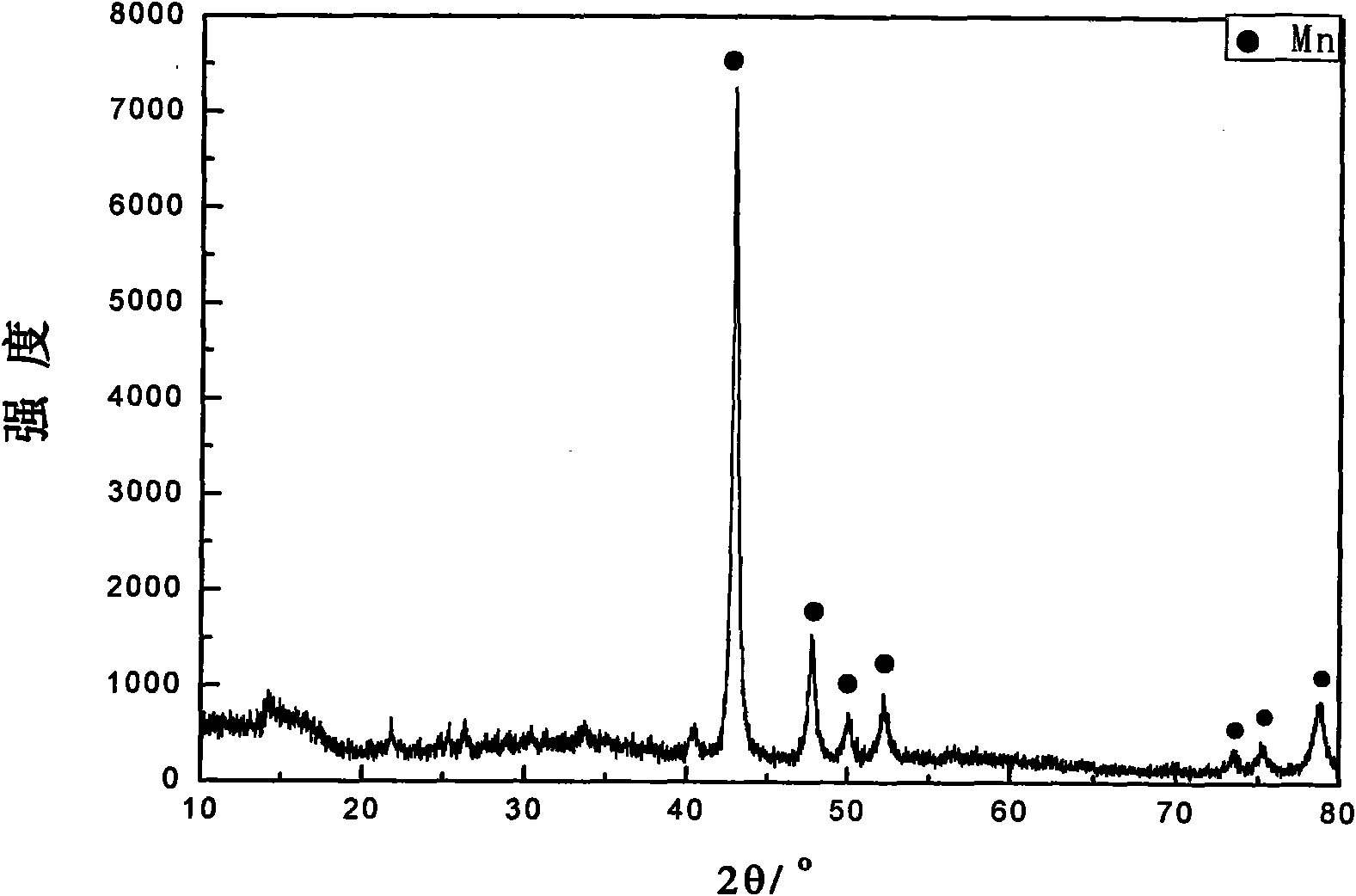

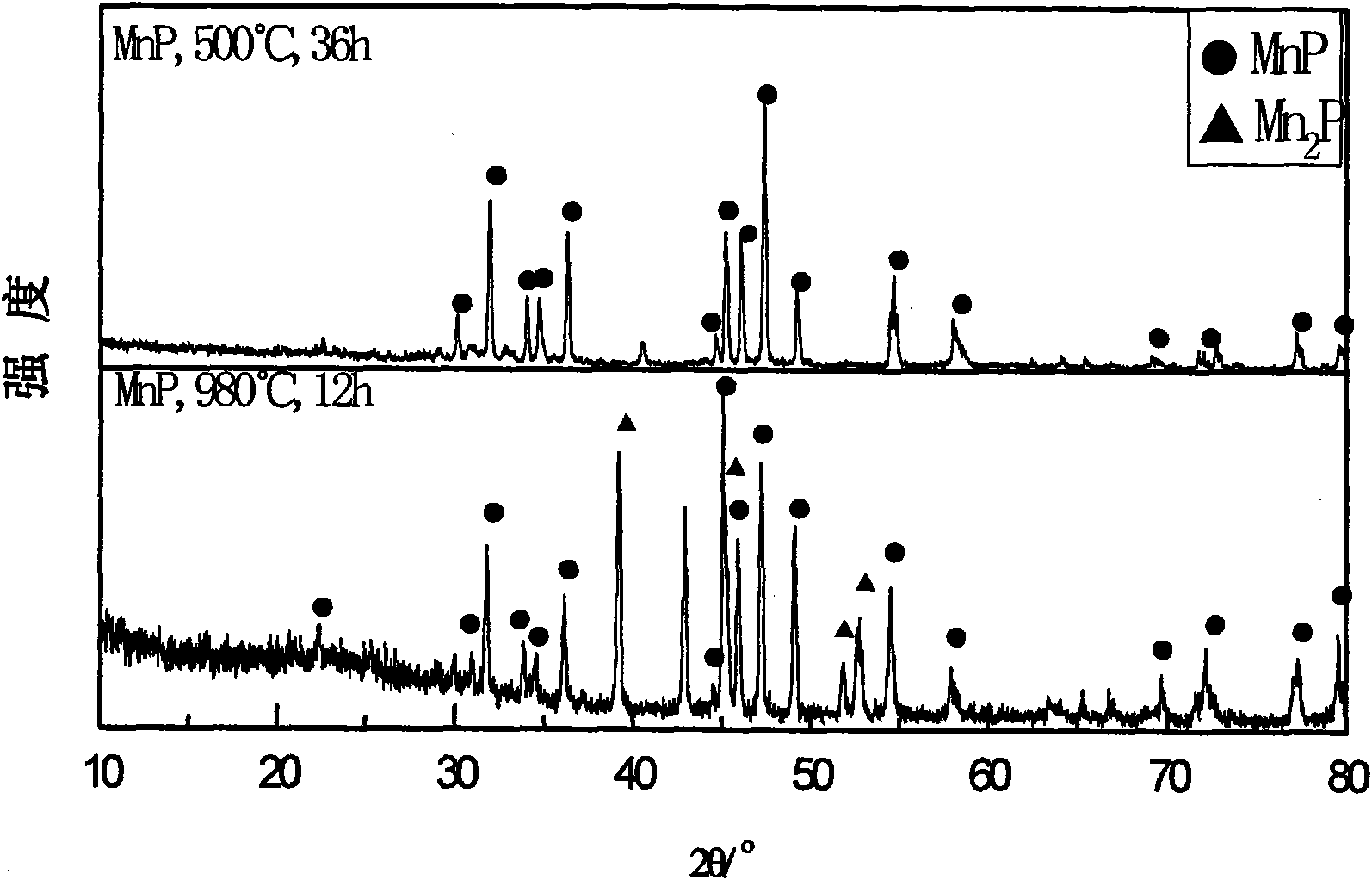

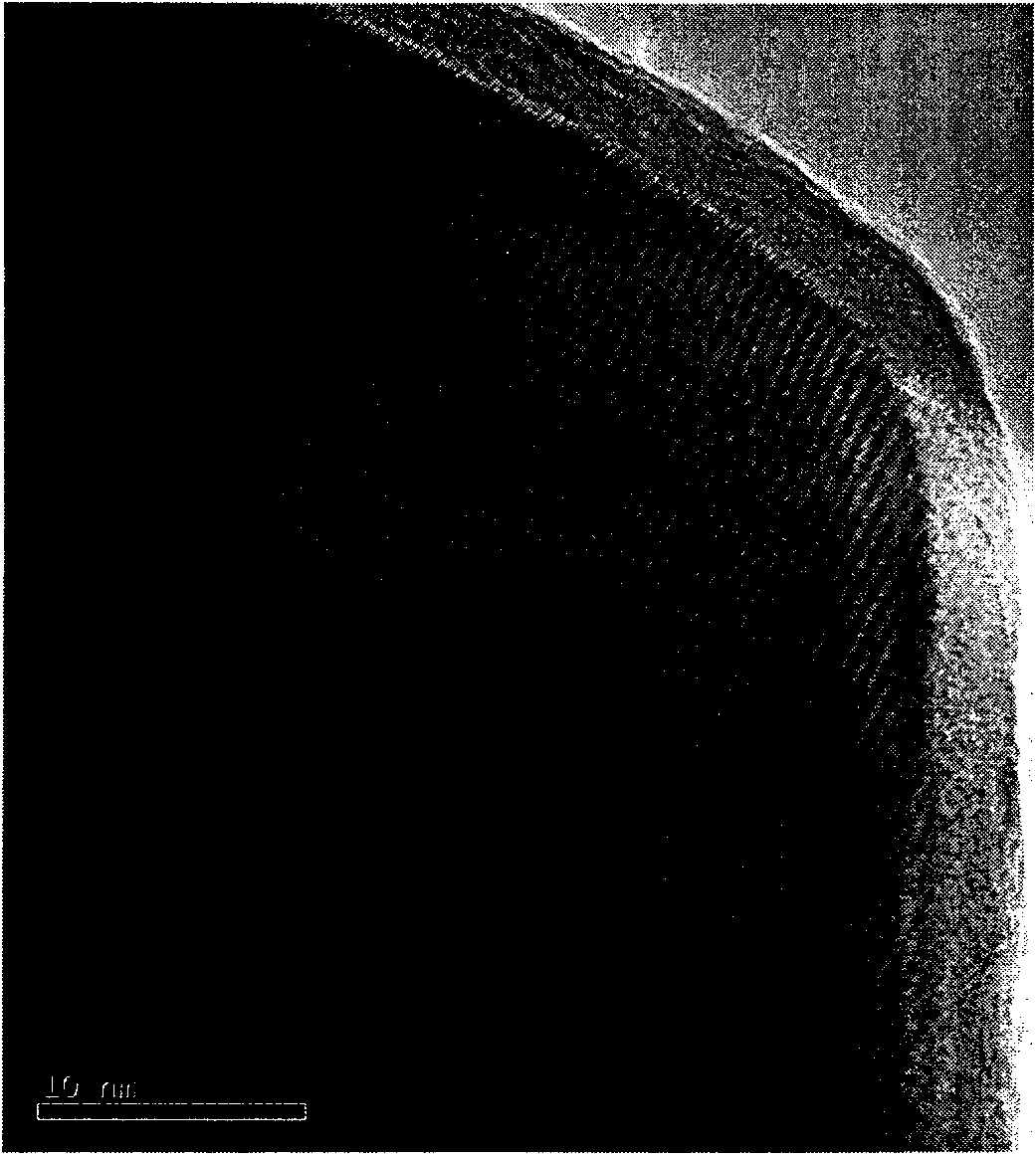

[0035] The ratio of manganese to phosphorus (Mn:P) is 50%:50%. Weigh manganese powder and red phosphorus powder according to the stoichiometric ratio Mn:P=50%:50% (that is, the molar ratio of manganese to phosphorus is equal to 1:1), and put them into a sealed ceramic ball mill jar with a ball-to-material ratio of 5:1. Under an argon atmosphere, ball milling was performed. The ball mill was ball milled at room temperature at a speed of 400 rpm for 40 hours. The phase structure after ball milling is shown in figure 1 . It can be seen from the figure that manganese Mn still appears in crystalline state after ball milling, while phosphorus P appears in amorphous state. Apart from this, no other phases are formed. The powder obtained after ball milling was pressed into tablets and placed in a tube furnace. In an argon atmosphere, the temperature was gradually raised to 980°C. At this temperature, pre-fired for 12 hours. After naturally cooling to room temperature, the pre-c...

Embodiment 2

[0039] The ratio of manganese to phosphorus (Mn:P) is 25%:75%. The preparation method of this embodiment is the same as that of Example 1. Weigh manganese powder and red phosphorus powder according to the stoichiometric ratio (Mn:P=25%:75%) (that is, the molar ratio of manganese to phosphorus is equal to 1:3), and put them into a sealed ceramic ball mill jar with a ball-to-material ratio of 8. : 1. Under an argon atmosphere, ball milling was performed. The ball mill is at room temperature with a rotating speed of 400 rpm, and the ball milling time is 40 hours. The phase structure after ball milling and figure 1 Similarly, manganese Mn still appeared in crystalline state after ball milling, while phosphorus P showed amorphous state without other phases formed. The powder obtained after ball milling was pressed into tablets and placed in a tube furnace. In an argon atmosphere at atmospheric pressure, gradually raise the temperature to 950°C. At this temperature, pre-fired ...

Embodiment 3

[0042] The tin-phosphorus feed ratio (Sn:P) is 15%:85%. The preparation method of this embodiment is the same as that of Example 1. Weigh tin powder and red phosphorus powder according to the stoichiometric ratio (Sn:P=15%:85%) (that is, the molar ratio of tin to phosphorus is equal to 3:17), and put them into a ceramic ball mill jar with a ball-to-material ratio of 10:1 . Under an argon atmosphere, at a rotational speed of 100 rpm, the ball milling time was 50 hours. The phase structure after ball milling and figure 1 resemblance. At room temperature, the powder obtained after ball milling was pressed into tablets and placed in a tube furnace. In an argon atmosphere at normal pressure, the temperature was gradually raised to 400°C. At this temperature, pre-baking was performed for 30 hours. After naturally cooling to room temperature, the pre-calcined product was ground into powder, pressed into tablets and placed in the tube furnace again. In an argon atmosphere at at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com