Methane vapor reforming hydrogen production process and devices thereof

A methane water vapor, reforming hydrogen production technology, applied in the direction of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of the separation of adsorbent and catalyst, the service life of adsorbent is small, the service life of catalyst and so on, so as to achieve high equipment cost, The effect of reducing equipment costs and reducing material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

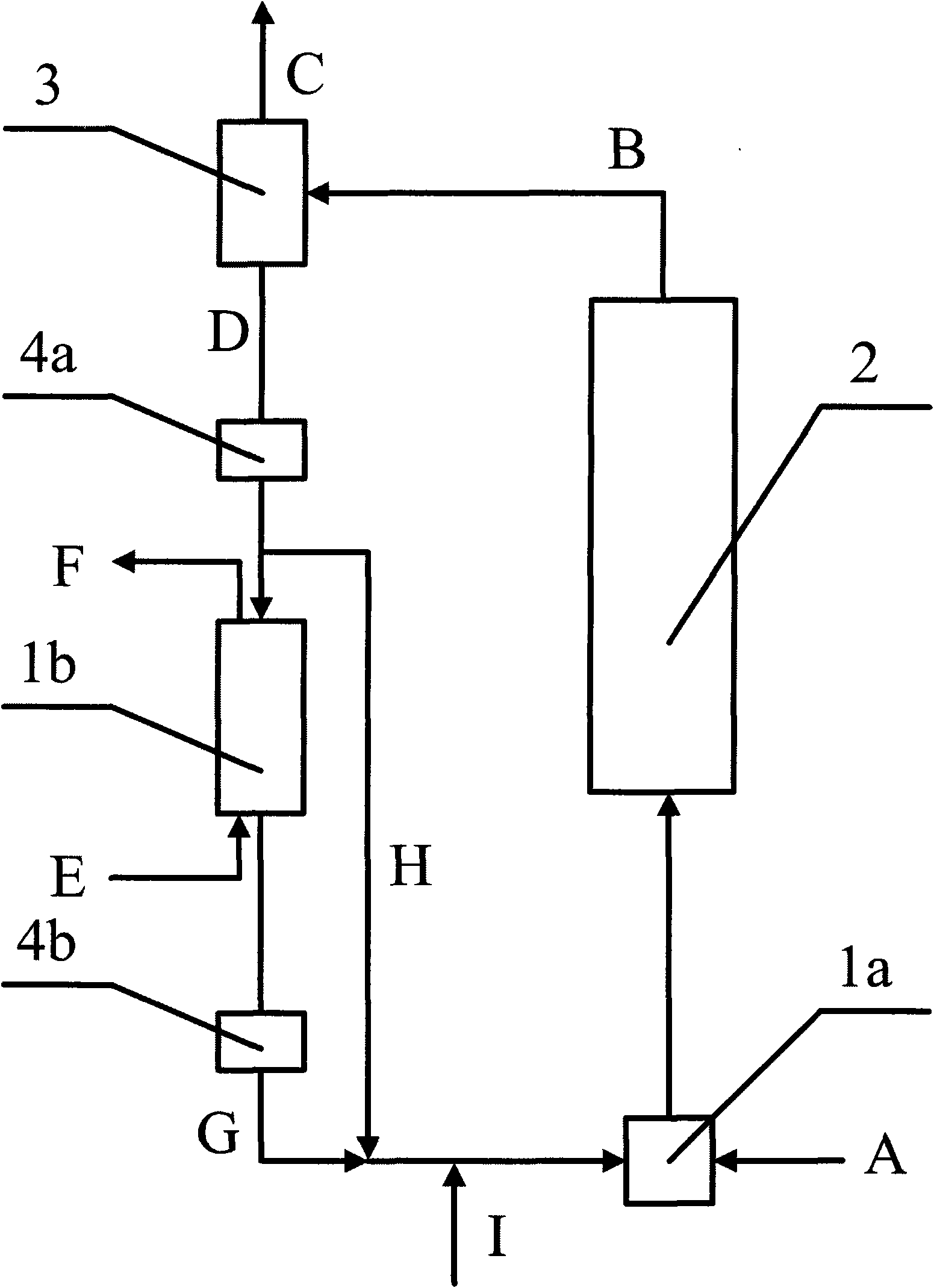

[0024] like figure 1 In the shown gas-solid-solid adsorption enhanced methane steam reforming hydrogen production device, the feed gas A and CaO particles are fully mixed in the mixer 1a. After mixing, the gas temperature is 650°C, the pressure is 15atm, and the adsorbent The volume fraction is 5%; the molar ratio of water vapor and methane in feed gas A is 4, and the total volume flow rate is 5m 3 / h; the diameter of the catalyst particle is a cylinder with a length of φ10mm and a length of 6mm, and there is a clover-like channel in the cylinder; the inner diameter of the gas-solid-solid reactor is 100mm, and the height of the catalyst bed is 400mm; the particle diameter of the adsorbent is 30 microns; During each cycle, 10% of the adsorbent enters the regeneration reactor to regenerate at 900°C, and the adsorbent enters the next cycle of operation after regeneration; the other 90% of the adsorbent does not pass through the regeneration reactor, and 89.5% of the adsorbent dire...

Embodiment 2

[0026] like figure 1 In the shown gas-solid-solid adsorption enhanced methane steam reforming hydrogen production device, raw material gas A and the mixture particles of CaO and MgO formed by calcination of dolomite are fully mixed in the mixer 1a, and the gas temperature after mixing is 600 ℃, the pressure is 10atm, the volume fraction of the adsorbent is 5%; the molar ratio of water vapor to methane in the feed gas A is 4, and the total volume flow rate is 5m 3 / h; the particle size of the catalyst particle is a cylinder with a length of φ20mm and a length of 15mm, and there is a clover-like channel in the cylinder; the inner diameter of the gas-solid-solid reactor is 100mm, and the height of the catalyst bed is 400mm; the particle size of the adsorbent is 25 microns ;During each cycle, 10% of the adsorbent enters the regeneration reactor to be regenerated at 900°C, and the adsorbent enters the next cycle of operation after regeneration; the other 90% of the adsorbent does n...

Embodiment 3

[0028] like figure 1 In the shown gas-solid-solid adsorption enhanced methane steam reforming hydrogen production unit, raw material gas A and CaO and Al 2 o 3 (Particulates mixed in a mass ratio of 1:1) The mixture is fully mixed in the mixer 1a, the gas temperature after mixing is 650°C, the pressure is 3atm, and the volume fraction of the adsorbent is 7%; in the feed gas A, water vapor and The molar ratio of methane is 2 and the total volumetric flow rate is 5m 3 / h; the particle size of the catalyst particle is a cylinder with a length of φ10mm and a length of 6mm, and there is a clover-like channel in the cylinder; the inner diameter of the gas-solid-solid reactor is 100mm, and the height of the catalyst bed is 400mm; the particle size of the adsorbent particle is 15 microns ;During each cycle, 10% of the adsorbent enters the regeneration reactor to be regenerated at 900°C, and the adsorbent enters the next cycle of operation after regeneration; the other 90% of the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com