Method for preparing ammonium chloride from waste in amino acid production

A technology of ammonium chloride and waste, applied in the direction of ammonium halide, etc., can solve the problems of inability to use in large quantities, limited digestion, environmental pollution, etc., and achieve the effects of low raw material prices, obvious value-added effects, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention separates and purifies the ammonium chloride from the wastes of amino acid production. The waste is in the form of a solid slag with a certain viscosity, which contains ammonium chloride, sugar, water and impurities.

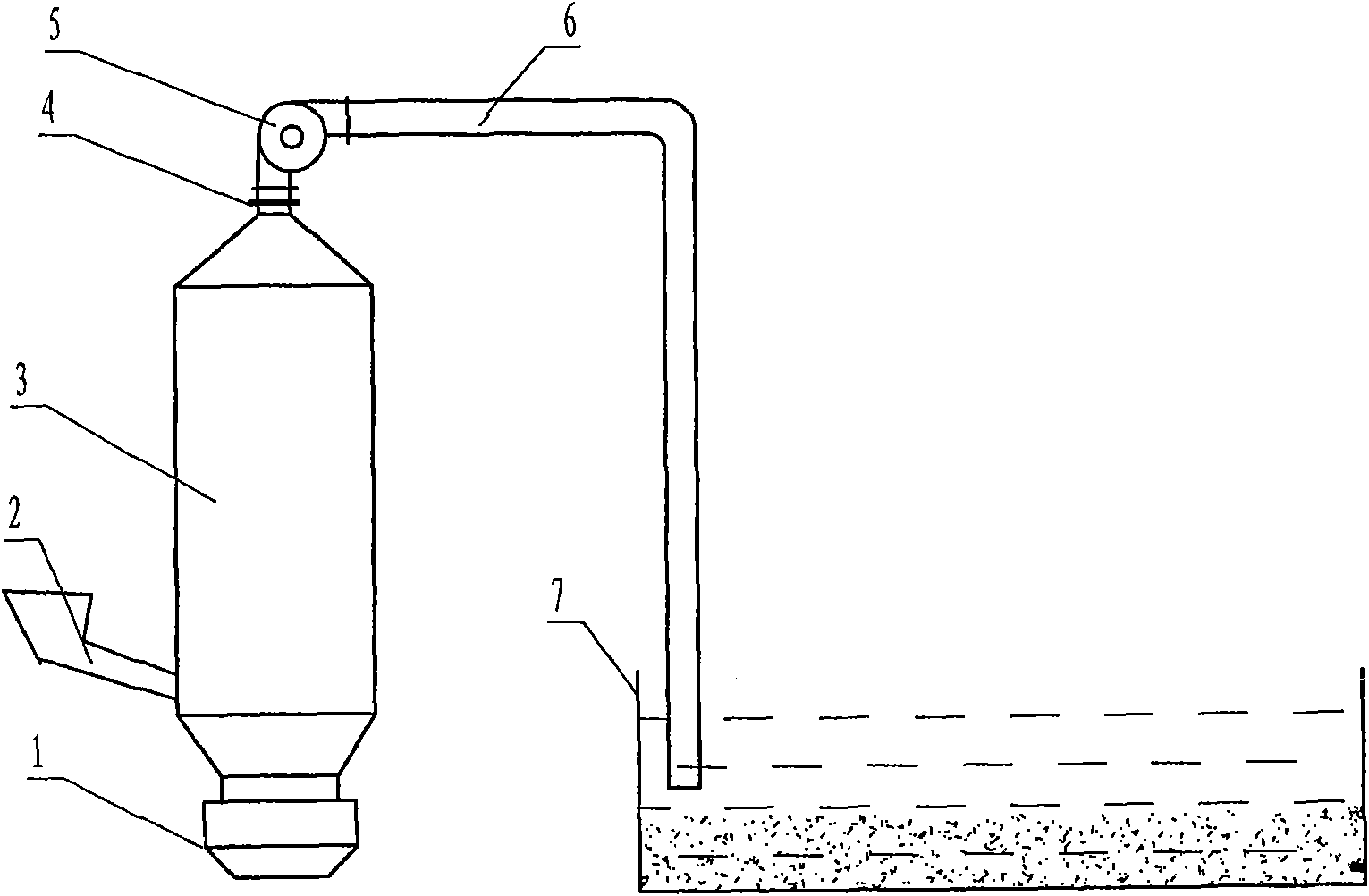

[0016] According to the sublimation and gasification of ammonium chloride at 340°C (heat of sublimation 314.2KJ / mol), and the carbonization of sugar at greater than 400°C, the sugar-containing ammonium chloride is put into the incinerator from the feed port 2 of the incinerator 3 for high-temperature incineration. During the process, ammonium chloride is sublimated into gas, the sugar is carbonized and carbon dioxide gas is released, and the impurities are incinerated and become ashes. The carbonized sugar is discharged from the lower part of the incinerator to the ash hopper 1; the mixed gas of ammonium chloride and carbon dioxide produced by incineration is passed through the exhaust fan. 5 and flue 6 collect and discharge in the water-sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com