FRP rib fibre cloth winding coaxial connection method

A technology of coaxial connection and fiber cloth, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problem that FRP bars do not have weldability, cold bending, extrusion strength and interlayer performance, and are not suitable for use Lashing lap joints and other issues to achieve the effect of light weight, small size and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

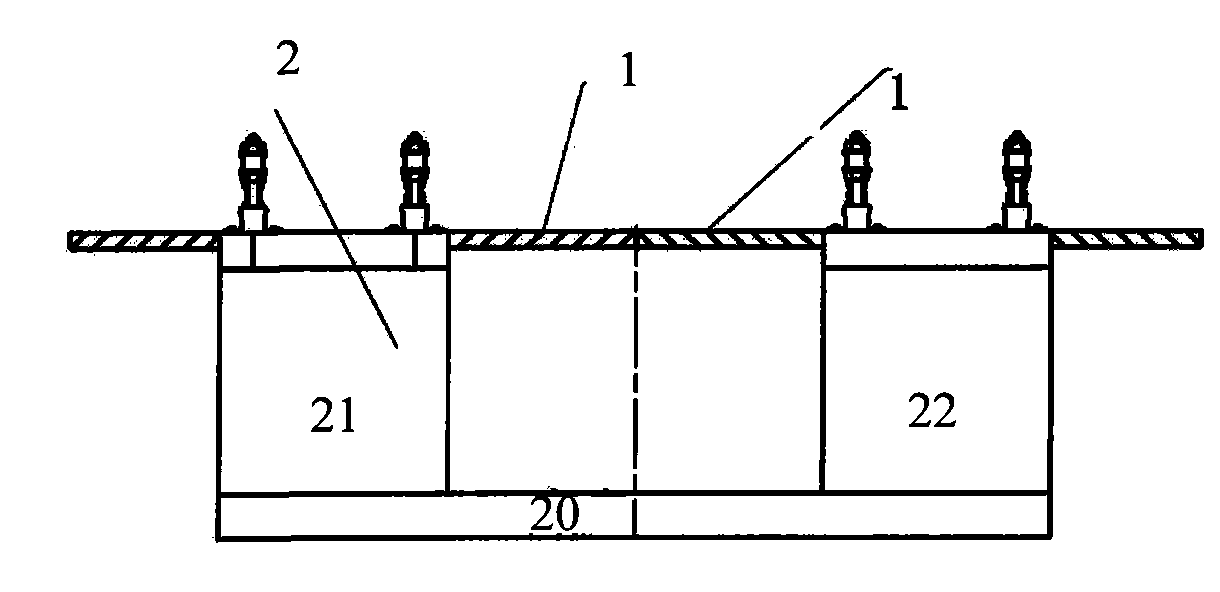

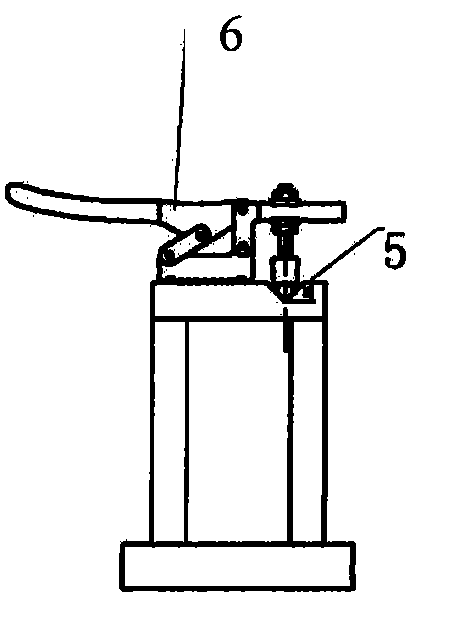

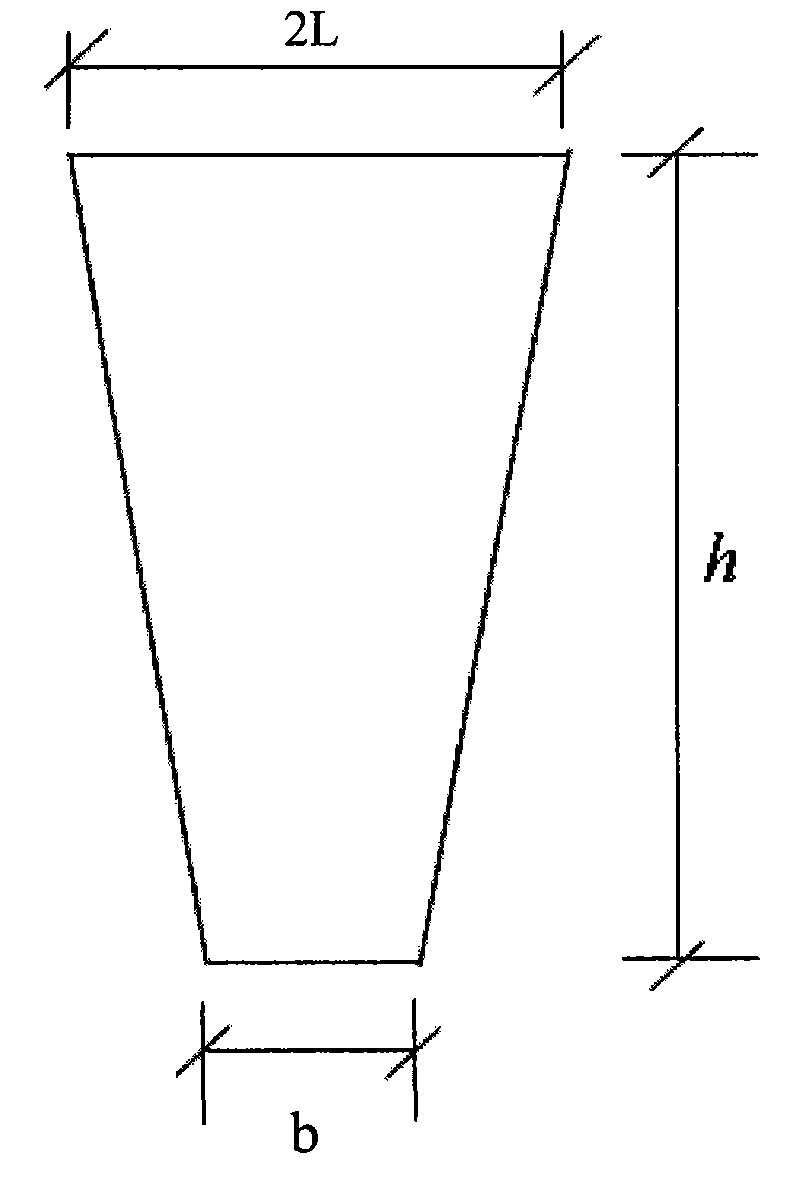

[0026] Two FRP bars 1 to be connected are placed on a special coaxial centering bracket 2 for connection (such as figure 1 ) for centering and positioning, and the ribs fixed on the bracket 2 are required not to slip or displace during the subsequent winding of the fiber cloth, and then select the appropriate fiber cloth 3 for winding according to the specifications and performance of the connected ribs 1 Specifications (you can choose unidirectional fiber cloth or non-weft cloth with a vertical and horizontal fiber ratio of 4:1, 7:1 or 11:1, and the fibers can be glass fiber, carbon fiber, aramid fiber, basalt fiber, etc.), and According to the fiber cloth 3 impregnated with resin wrapped around the joint part, the composite material obtained after solidification should have a tensile capacity not lower than that of the FRP tendon body, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap