High-humidity smoke sampling sulfur dioxide separating device

A technology of sulfur dioxide and separation device, which is applied in the direction of sampling device and test sample preparation, etc., which can solve the problems of sulfur dioxide dissolution loss and achieve the effect of reducing dissolution loss and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

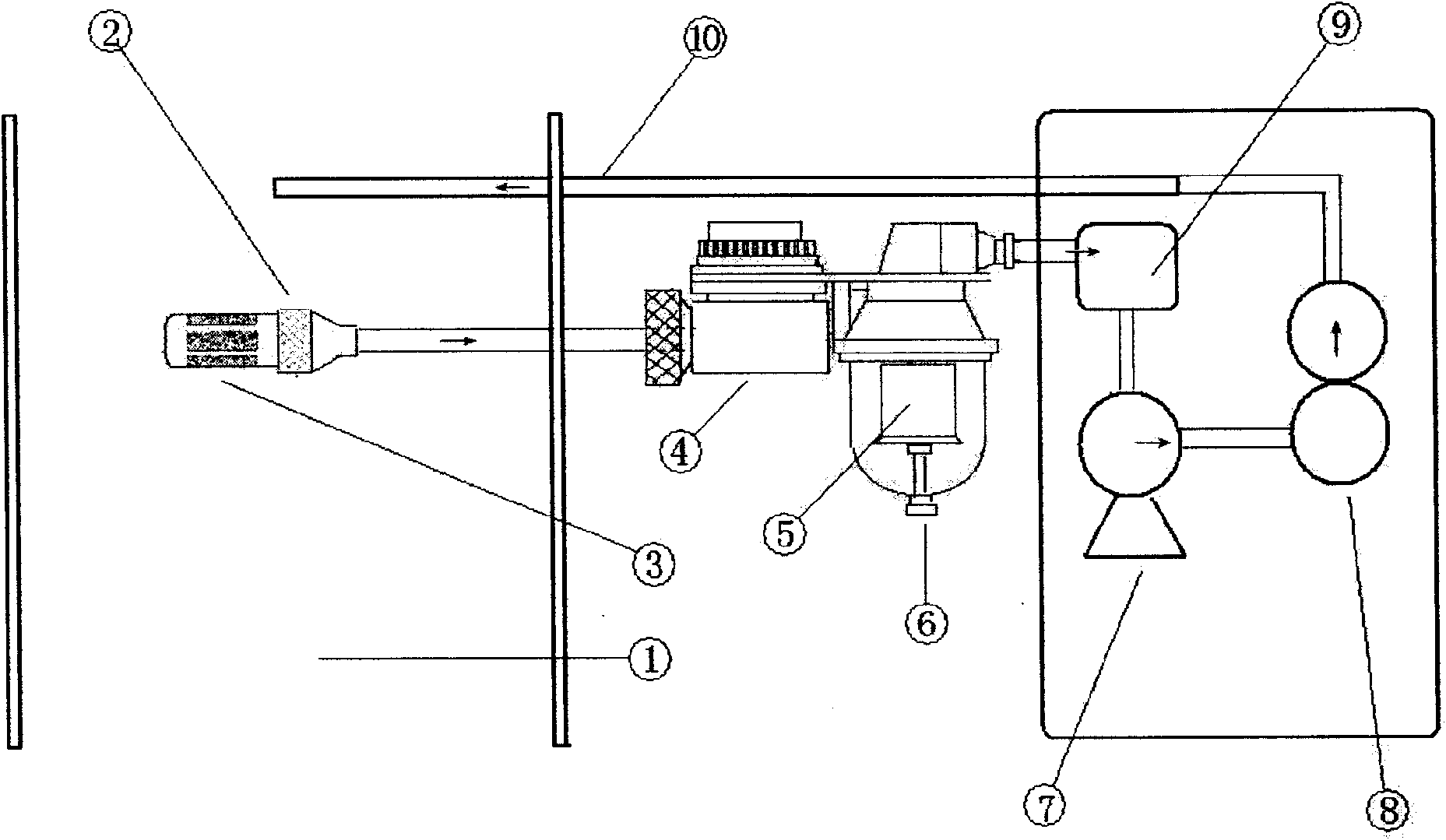

[0016] As shown in the accompanying drawings, insert the device of the present invention into the flue (1), start the suction pump (7), and the direction of the smoke in the pipeline is shown by the arrow in the figure. In the flue, the flue gas enters the sampling gun head (2) through the micropores of the hydrophobic and gas-permeable membrane (3), and the area of the hydrophobic and gas-permeable membrane must be large enough to maintain the gas sampling flow. Most of the water mist in the flue is blocked from the gun. When the flue gas containing a certain amount of water vapor reaches the overheater (4) through the sampling gun rod, the temperature rises sharply, and the chemical reaction of sulfur dioxide dissolving in water takes place reversibly, that is, the sulfurous acid is decomposed into sulfur dioxide and water:

[0017] h 2 SO 3 =SO 2 +H 2 o

[0018] And the hydrophobic gas-permeable film (5) of the water-gas separator (6) following it has blocked most of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com